For the Royal Shakespeare Company, raising the roof is second nature – but raising the stage required support from Hydraulics Online

The Royal Shakespeare Company (RSC) welcomes over one million visitors annually to its Stratford-upon-Avon theatres, drawn by its world-class productions, enchanting Christmas shows, and interactive workshops. Celebrated for staging some of the finest theatrical interpretations of Shakespeare’s plays, the RSC continues to push creative boundaries in live performance.

So when the company prepared to stage Wendy and Peter Pan at its flagship Royal Shakespeare Theatre, the team set out to create something truly magical for its family audiences. Behind the scenes, delivering that magic required precision engineering – and that’s where Hydraulics Online entered the spotlight.

“Nobody could beat Hydraulics Online on price.” – Gill Leefe, Control Systems Engineer, RSC

Control Panel Systems for Heavy Lifting

At the Royal Shakespeare Company (RSC) in Stratford-upon-Avon, Control Systems Engineer Gill Leefe oversees the operation of the theatre’s custom hydraulic system – powered by a dedicated mains supply and designed for heavy-lifting stage automation.

“There are important safety considerations when using hydraulic equipment and we have to be very careful,” says Gill. “But they’re incredibly useful in theatre – especially when big, heavy things need to move.”

One of the most striking uses of the system came during the production of Wendy and Peter Pan, where Hydraulics Online’s custom-built hydraulic control panel played a pivotal role.

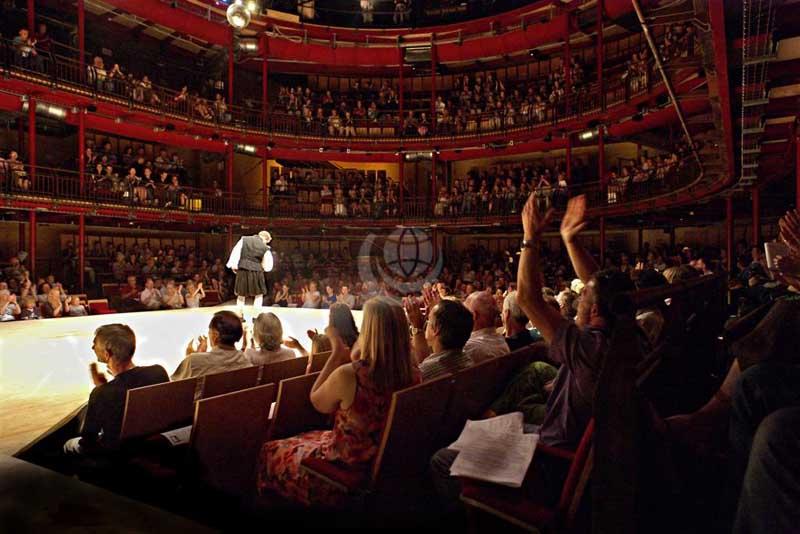

“While Wendy is searching for the Lost Boys, the stage begins to rise – revealing Tinkerbell underneath,” Gill explains. “In that elevated space, another piece of set emerges to unveil the hidey-hole, with eleven boys dancing. The effect is breathtaking.”

Two independent controllers were seamlessly linked to a central hydraulic control panel, orchestrating the synchronised movement of complex stage elements. One actor was securely strapped to a moving set piece, while a second platform lifted multiple performers – making flawless hydraulic performance absolutely essential.

Sometimes I operated that show and from where I sat I could see the front row of kids. When the stage began to lift up they would jump out of their seats, wondering what was going on. Then I could see the expressions of wonder on their faces; they were really excited. It was an absolutely brilliant moment.

These systems proved their durability beyond one production. The same equipment was used at London’s Barbican Theatre for King Lear starring Sir Antony Sher. After its run, the rig returned to Stratford-upon-Avon for full reconditioning.

When Gill needed to replace a Parker dual-driver multifunction proportional valve, a quick online search pointed straight to Hydraulics Online – a trusted supplier capable of sourcing precision components for high-spec theatrical applications.

Great Service That Delivers Centre Stage

“The team at Hydraulics Online were really efficient and friendly.” – Gill Leefe, Control Systems Engineer, Royal Shakespeare Company

Sometimes we are not the easiest people to deal with because we can generate a lot of paperwork; taking on a new supplier can be a lengthy process for us, but Hydraulics Online worked very quickly and made it really easy for us – Gill Leefe, Control Systems Engineer, RSC.

For the Royal Shakespeare Company, taking on a new supplier involves detailed paperwork and rigorous approvals – but Hydraulics Online made the process refreshingly simple. Despite the administrative challenges, the team responded quickly, professionally, and with complete ease.

Gill did explore alternatives for sourcing a suitable part, but came to a clear conclusion:

“I called around for alternative quotes, but nobody could match Hydraulics Online on price.”

The hydraulic control panel valve arrived ahead of the expected lead time, and the service throughout was flawless.

Hydraulics Online were very efficient and pleasant to deal with throughout and their price is the best. I will definitely be using Hydraulics Online again and would recommend them,

Now fully installed, the equipment continues to power performances – bringing theatrical magic to future RSC productions for years to come.

We are the first choice for customers in over 130 countries worldwide, supplying a vast selection of hydraulic brands and components. You are guaranteed impartial, technical advice and optimal solutions. Every time.

Discover more Success Stories from Hydraulics Online…

Success Story: Materials Handling

Rather than carrying multiple spare parts for different machines, this materials handling equipment provider turned to Hydraulics Online for a smarter, more flexible solution.

Read MoreHydraulics Online designed a solution that could do this for us – and overnight, we went from a six-week lead time to being able to offer a lead time measured in hours.

Ghost Bus Tours – "Who you gonna call?"

Routemasters are iconic British buses – engineering legends with unmistakable charm. But at over fifty years old, keeping them on the road is no easy task. When the power steering ram failed on one of Ghost Bus Tours’ vehicles, David, Head of Transport, was told by several suppliers it “couldn’t be repaired.”

In search of a second opinion, he contacted Hydraulics Online.

Read MoreAfter speaking with them, I knew these guys knew what they were talking about…

Lights, Camera, Action!

In live broadcasting, time is of the essence – and there’s no such thing as a second take. Adrian Croome, founder of Off Road Jib and a veteran of more than 25 years in television, had spent years manually levelling heavy camera rigs between sets and locations. He knew there had to be a better way – but assumed the solution would be too complex or costly to pursue.

Read MoreI didn’t know where to start and thought it would be too complicated and way too expensive to make it a reality.