Hydraulic engineering is based on scientific principles that govern how pressure behaves in liquids – and how hydraulic systems can multiply smaller forces into much larger ones.

Liquids are made up of closely packed particles, making them virtually incompressible. As these particles move, they collide with one another and with the walls of their container. Because of this, when a force is applied to a liquid, the resulting pressure is transmitted equally in all directions.

This principle is known as Pascal’s Law, named after the French mathematician Blaise Pascal. It means that if pressure is applied at one point in a confined liquid, it spreads out evenly to all other points.

Pressure is calculated using the equation:

Pressure (P) = Force (F) ÷ Cross-Sectional Area (A)

Where:

P = Pressure in pascals (Pa),

F = Force in newtons (N)

A = Cross-sectional area in metres squared (m2)

For example: A force of 100N is applied over an area of 5m2. What is the pressure?

P = F ÷ A

P = 100 ÷ 5

P = 20 Pa

Hydraulic Engineering

Pressure in a liquid is transmitted equally in all directions. This means that when a force is applied to one point of the liquid, it spreads to all other points within that liquid. Hydraulic engineering is based on this principle—and takes advantage of the fact that applying a small force over a small cross-sectional area can transmit pressure to generate a much larger force over a larger cross-sectional area.

Imagine connecting two syringes of different sizes with tubing and filling the system with water…

An “effort force” applied to syringe A increases the pressure of the water inside its tube. Since water is virtually incompressible, this pressure spreads evenly through the liquid and into syringe B. The water then pushes against the plunger in syringe B with equal pressure, exerting a “load force” on it.

However, syringe B has a plunger with a larger cross-sectional area than syringe A. As a result, the load force produced is greater than the original effort force applied to syringe A. This phenomenon is known as a “force multiplier.” It’s important to note that the larger syringe moves a shorter distance than the smaller one.

Hydraulic systems use this principle to multiply small forces into larger ones. A car braking system is a perfect example of this concept in everyday life.

We can now look at the diagram of a hydraulic jack to calculate the force on piston B.

To begin, we calculate the pressure of the liquid inside Piston A, using the familiar formula:

Pressure (P) = Force (F) ÷ Cross-Sectional Area (A)

Where:

- P = Pressure in pascals (Pa)

- F = Force in newtons (N)

- A = Cross-sectional area in square metres (m²)

Substitute the given values:

P = 30 ÷ 0.2 P = 150 Pa

Next, we calculate the force in Piston B. Since this is a closed hydraulic system, the pressure is transmitted equally in all directions—meaning the pressure in Piston B is also 150 Pa.

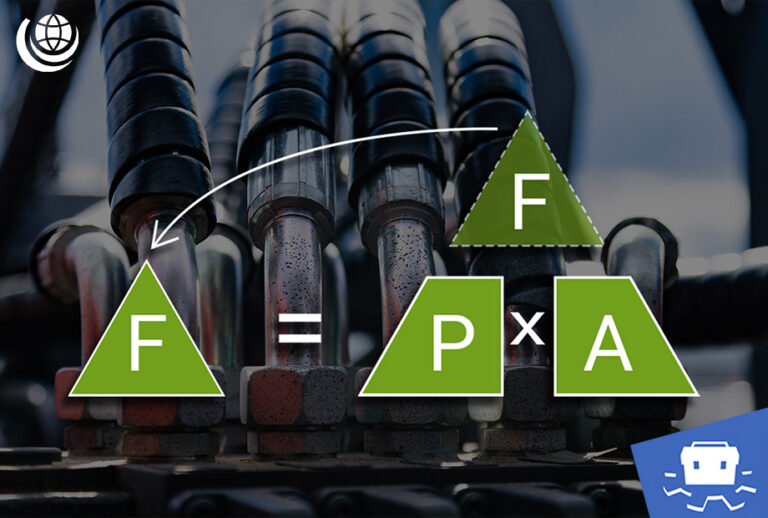

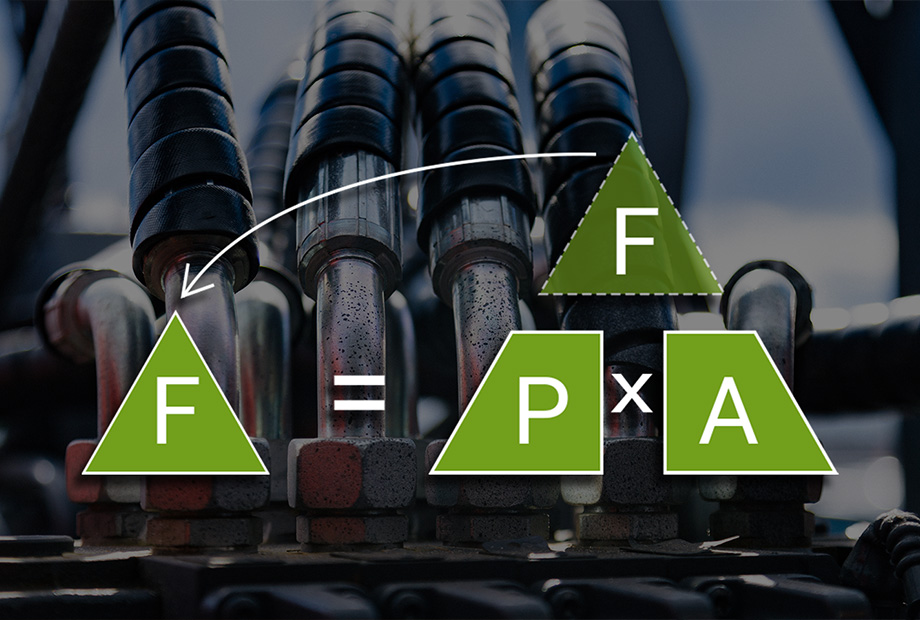

Using the same formula, rearranged:

Force (F) = Pressure (P) × Cross-Sectional Area (A)

Given that the cross-sectional area of Piston B is 1.0 m²:

F = 150 × 1.0 F = 150 N

This shows that the hydraulic jack can lift a load force five times greater than the original effort force of 30 N applied to Piston A.

Applications of Hydraulics

Hydraulic systems allow smaller forces to be multiplied into larger forces. Car braking systems are a perfect example of how this principle is applied in everyday life.

Slowing down or stopping a car travelling at speed requires a significant force. In a hydraulic braking system, a relatively small force from the driver’s foot is multiplied to create a greater force, acting evenly on all four brake pads.

When the driver presses the brake pedal, this effort force applies pressure to the brake fluid inside a small piston. That pressure is transmitted through the fluid in all directions.

Next to each brake disc is a larger piston with a greater cross-sectional area. The pressure acts on this larger piston to produce a greater load force on the brake pads. These pads then press against the brake discs, causing the car to slow down.

Hydraulic systems are everywhere around us and can be found in a wide range of applications, including: fairground rides, lifting equipment (such as passenger and goods lifts, diggers, and dentist chairs), winches on fishing boats, wind turbines, factories, security gates and barriers, commercial vehicle tail lifts, horse boxes, piling rigs, and aircraft—including the droop nose on Concorde.

We are the first choice for customers in over 130 countries worldwide, supplying a vast selection of hydraulic brands and components. You are guaranteed impartial, technical advice and optimal solutions. How can we help?

Find more hydraulics for beginners in our Fluid Power Technical Knowledge Hub…

An Introduction to Hydraulic Pressure and Flow

Hydraulic systems are based on the principles of fluid dynamics – the branch of science dealing with the movement of fluids.

One of the first concepts that must be understood is how physicists quantify the movement of fluids, namely flow.

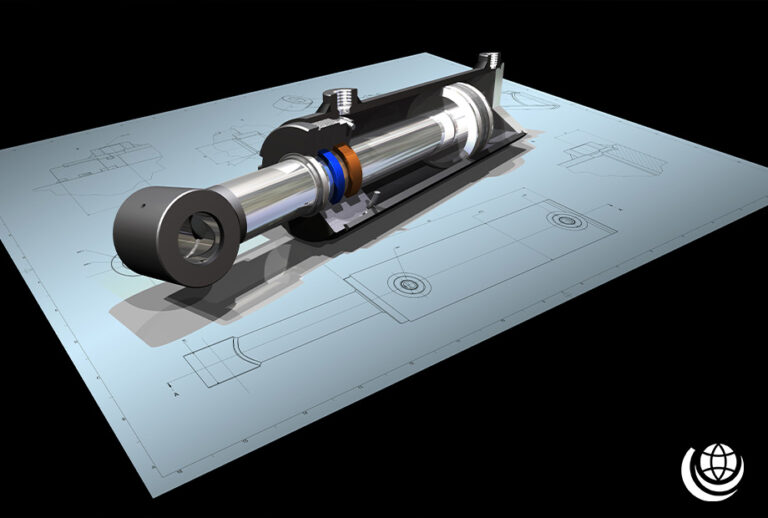

Learn MoreThe Vital Role of Hydraulic Cylinder Seals

Hydraulic cylinder seals are commonly found in applications where components are exposed to liquids. They play a vital role within the hydraulic system, as they enable the transfer of liquid power into linear motion.

Despite their durability, seals can fail or cause serious damage if the settings are not correct.

Learn MoreHydraulics Online Ebook Library

If you liked our “Hydraulics For Beginners” page, then check out our free hydraulics ebooks!

They cover a range of beginner- friendly topics including the history of hydraulics and a glossary containing the definitions to almost 500 hydraulic-related words and phrases!

Learn more