The iconic rising bascules of London’s Tower Bridge are stuff of folklore. The bridge has so many amazing real-life and fictional stories associated with it. However, perhaps its most interesting story is its engineering.

London’s iconic Tower Bridge has been the subject of some amazing stories over the years…

In 1952, bus driver Albert Gunter was happily driving the number 78 bus over Tower Bridge towards Shoreditch when the road in front of him seemed to drop away. Realising his bus was on a rising bascule, Gunter slammed his foot on the accelerator and cleared the gap.

It seemed that on that day, the watchman had failed to ring the warning bell and close the gates before the bridge opened. Luckily, Gunter cleared the gap and landed all of the twenty passengers on board, back to earth safely.

In the latter part of the twentieth century, rumours persisted that Tower Bridge was part of an elaborate ruse. American businessman Robert McCulloch bought London Bridge in 1968 for a cool $2.4 million as a focal point for a development in Arizona. It was suggested McCulloch made the investment thinking the bridge he was buying was, in fact, Tower Bridge. However, this notion seems to be roundly disproved by a picture of McCulloch standing on the old London Bridge when signing the purchase paperwork!

In the 1990s, Tower Bridge was at the centre of a diplomatic incident after Tony Blair took Bill Clinton to lunch at the Pont de la Tour restaurant beside the Thames…

On route back to the American Embassy, the US president was stranded on one side of the bridge, with his security detail on the other after the bascules began to rise! An old sailing barge had booked the bridge opening and the White House hadn’t been informed. Although Scotland Yard ordered the bridge be closed so the President could rejoin his security detail, the police officers were informed that river traffic takes precedence over road traffic by law – and the Clintons were forced to wait!

The ground-breaking engineering of Tower Bridge

Fascinating though these stories are, here at Hydraulics Online we think that some of the most interesting stories about Tower Bridge relate to its engineering and its operation.

Excitingly for hydraulics fans like us, throughout its entire history and through multiple upgrades, one thing has remained constant: the lifting of Tower Bridge’s iconic bascules is – and has always been – powered by hydraulics.

It was ground-breaking back in 1894 and, thanks to Bosch Rexroth, is still ground-breaking today: updated over recent years, Tower Bridge now features modern hydraulic systems with cutting-edge technology that leverages the innovations of the Industrial Internet of Things (IIoT).

Why a drawbridge couldn’t work

Did you know that the bridge’s designer originally conceived Tower Bridge as a drawbridge? Early designs show this was the case. When the architect Sir Horace Jones first submitted his design, he intended the roads to lift as they would on a drawbridge on a mediaeval castle.

However, it soon became clear that the roads would be too heavy to lift as a drawbridge. The towers would not withstand the forces if the bridge was opened using chains suspended from the towers. Instead, the two halves of the road across the river would be lifted using a “bascule” mechanism.

Each bascule moves around an off-centre pivot. Each side of the bascule is evenly balanced, so no pressure needs to be put on the towers during the opening and closing of the road. The use of the bascules also means that less energy is required to open the road. The hard work is undertaken by eight large cogs, four on each side.

Hydraulics power the bridge opening and closing

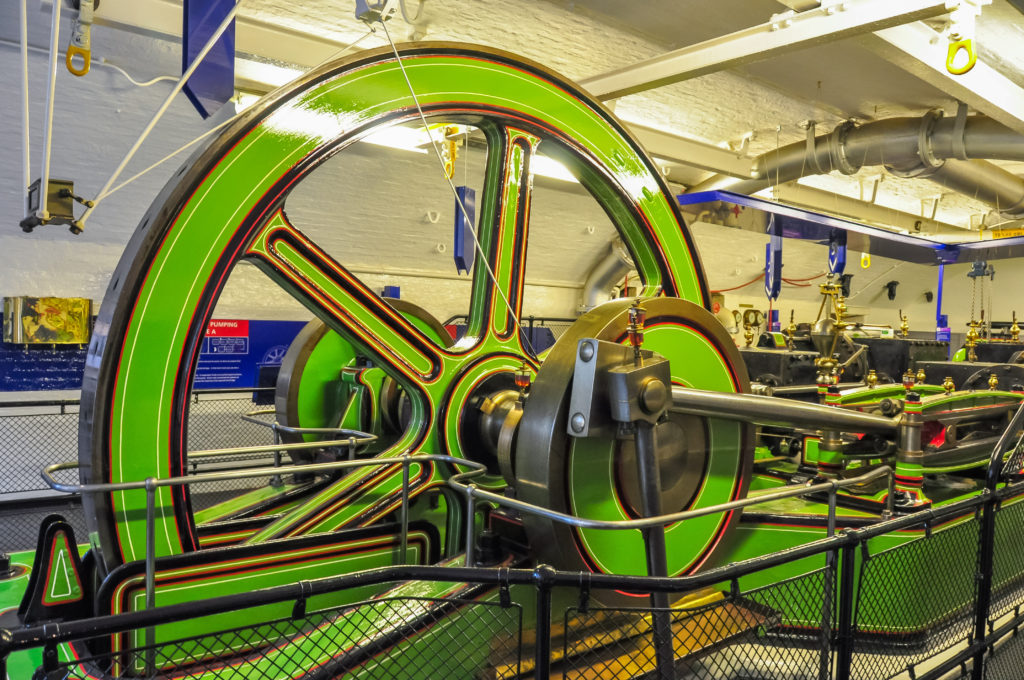

Each of the eight cogs used to pivot the bascule measures around a metre wide. Their rotation opens and closes the bridge. The power to rotate the cogs was originally supplied by a steam-powered hydraulic system.

Steam was the energy of choice for most of the 1800s. The three large boilers in the Tower Bridge engine room were supplied by the London Hydraulic Power Company. At the time, the company supplied hydraulic systems across London to power cranes, lifts, workshop machinery and even at the theatre!

The golden age of steam

The Tower Bridge steam engines powered a set of hydraulic pumps, which pushed water into large storage containers called accumulators. The accumulators hold the water under high pressure – thereby storing the energy, a bit like giant batteries.

The water would be released into the drive engines when the bridge was required to open. The drive engines powered the pistons which turned the cogs. The cogs then connect to a rack on the rear of each of the bascules to open them so that ships can sail up the river.

In the first year after the bridge was first built, more than 6,000 ships sailed through the open bascules of Tower Bridge. However, as the river traffic declined over the 20th century, steam was no longer an efficient way to power the bridge’s mechanism.

Switching to an electric hydraulic system

By 1970, the bridge was opened only a few hundred times each year. Keeping the coal-fired furnaces running to produce the steam required to power the hydraulic system was no longer an efficient way of working. Furthermore, the city had clean air objectives to meet.

Instead, it was determined that a new oil-based hydraulic system powered by electricity would be cleaner and more economical. The bridge operators turned to industrial specialists Bosch Rexroth to help make the switch to the new hydraulic system. The old steam room was retired but the hydraulic system was preserved and you can still view it if you take a tour of the bridge today.

Leveraging the continual advances in hydraulic technology

The installation of the new electro-hydraulic system was begun in 1974. Electric pumps were used to pump the hydraulic oil around the new hydraulic system. Just as in the old system, this hydraulic energy would then be used to turn the big cogs that open the bascules.

The steam system continued to operate until the new electric-powered hydraulic system was installed and fully tested. The work was completed in 1976. At that point, the switch to the new system was made and the old steam-powered hydraulic system became little more than a tourist attraction.

Since the 1970s, hydraulic technology has continued to advance. During that period, Bosch Rexroth has worked with the City of London and Tower Bridge teams to continually enhance the hydraulics that power the bridge’s iconic movement. Over the last forty years that Bosch Rexroth have helped to maintain this wonderful London landmark, the hydraulic motors have been replaced for more efficient, modern motors. In the late 1980s, enhancements were made to the pump control, with fail-safe features and full back-up capabilities.

The system has been further upgraded recently to bring the bridge’s control system fully into the digital age and utilise the advances of the Industrial Internet of Things. This includes enhanced interfaces for monitoring and the delivery of operational efficiencies for an improved maintenance and service programme.

What's Next?

»

»

See it Yourself!

You can see the original hydraulic systems when you visit Tower Bridge.

In the meatime, you can visit the official site here to learn more about this world-renowned attraction.

Bosch Rexroth

If you’d like to see a selection of products from Bosch Rexroth, the brand behind Tower Bridge’s modern hydraulic systems click here.

Bosch RexrothThe UK's Hydraulic Landmarks and Attractions

Or for more inspiration about the wonderful world of hydraulics, read about other amazing hydraulic landmarks and attractions here.

Read more