Taking the proper precautions during hydraulic cylinder storage is essential to preserving performance and preventing avoidable damage…

Fact: prevention is better than cure. So, here are some top tips to help ensure your storage procedures are up to scratch – and your cylinders stay in perfect condition until they’re called into service.

Keep a Clean and Dry Storage Area

Protecting hydraulic cylinders begins with the environment. Always store cylinders – regardless of size – in a clean, dry space, and ideally indoors, where humidity, dust, and temperature fluctuations are controlled.

Doing so:

- Prevents corrosion and pitting on polished rod surfaces

- Minimises exposure to airborne contaminants that could enter seals

- Preserves cleanliness of ports and threads for faster, trouble-free installation later

- Avoids condensation and moisture buildup that could degrade seals and fluids over time

Even simple precautions like raising cylinders off concrete floors or using desiccant packs in enclosed storage can make a difference. It’s one of those habits that pays dividends in reliability and service life.

Cover Exposed Metal to Prevent Corrosion

One of the most effective ways to preserve hydraulic cylinders during storage is to protect exposed metal surfaces from rust and wear, especially the chrome rod. Key protection practices are to:

- Apply grease to internal components and threads to prevent oxidation and moisture intrusion

- Wrap oil-infused tape around the exposed chrome rod for long-term corrosion resistance

- Retract the rod fully before applying tape to avoid damaging the rod seal

- Use protective covers or end caps to shield mounting surfaces, fittings, and flanges from dust and impact

By creating a physical and chemical barrier against moisture, contaminants, and temperature fluctuation, these steps help ensure your hydraulic cylinder storage strategy keeps components in top condition and ready for future use.

Temperature Control in Hydraulic Cylinder Storage

Temperature plays a critical role in preserving cylinder integrity during storage. When cylinders are empty, they’re typically filled with air. If this air contains moisture and the ambient temperature drops below dew point, condensation forms inside the cylinder – leading to rust, pitting, and seal degradation. These issues compromise performance and dramatically reduce service life once the cylinder is reinstalled.

Best practices for temperature-related storage are to:

- Clean the cylinder thoroughly before storage to remove any contaminants or moisture

- Fill with clean oil to displace air and inhibit internal corrosion

- Be mindful of seasonal shifts:

- A cylinder stored in winter and reactivated in summer may experience thermal expansion or viscosity changes

- Always verify fluid condition before reinstallation

A stable temperature environment – ideally indoors – is key to minimising thermal stress and protecting internal components. In the context of hydraulic cylinder storage, temperature awareness isn’t just about comfort – it’s about safeguarding reliability.

Filtered Oil Precautions for Safe Hydraulic Cylinder Storage

Introducing filtered oil into a hydraulic cylinder during storage can be beneficial – but only if done with the proper safeguards to avoid unwanted pressure buildup and ensure long-term safety. Essential safety measures are:

- Monitor temperature variations Sudden ambient shifts can cause static pressure increases. Never allow these to exceed the cylinder’s operating pressure

- Fill only through the rod-port with the rod fully retracted This method avoids trapped pressure spikes and ensures safe internal fluid distribution

- Use service port plugs or blanks rated for cylinder pressure These components maintain system integrity during storage and prevent unregulated leaks or breaches

- Clearly label all service ports with warnings This ensures safe handling by operators, technicians, or anyone accessing the cylinder post-storage

- Provide a safe method to release pressure before opening service ports Pressure checks should be mandatory prior to disconnecting or servicing any sealed storage unit

- Prevent pressure intensification during reinstallation Cylinders exposed to long-term storage and alternating temperatures can develop trapped pressure. Always inspect and relieve before use

These practices aren’t just good storage hygiene – they’re necessary for protecting hardware, ensuring operator safety, and making sure your hydraulic cylinder storage meets professional standards.

Protecting Hydraulic Cylinders Starts with Smart Storage

Safe and effective hydraulic cylinder storage isn’t just about keeping cylinders out of harm’s way – it’s a proactive strategy for preserving performance, extending lifespan, and avoiding costly downtime. With clean environments, proper sealing, temperature awareness, and filtered oil precautions, you create a foundation that ensures every cylinder is ready when needed. Prevention truly is better than cure – and in hydraulics, careful storage is the cure that keeps systems strong.

We’re a 'truly integrated hydraulics supplier', offering thousands of possibilities, trusted by customers in 130 countries worldwide… how can we help?

Learn more about Hydraulic Cylinders in our Fluid Power Technical Knowledge Hub….

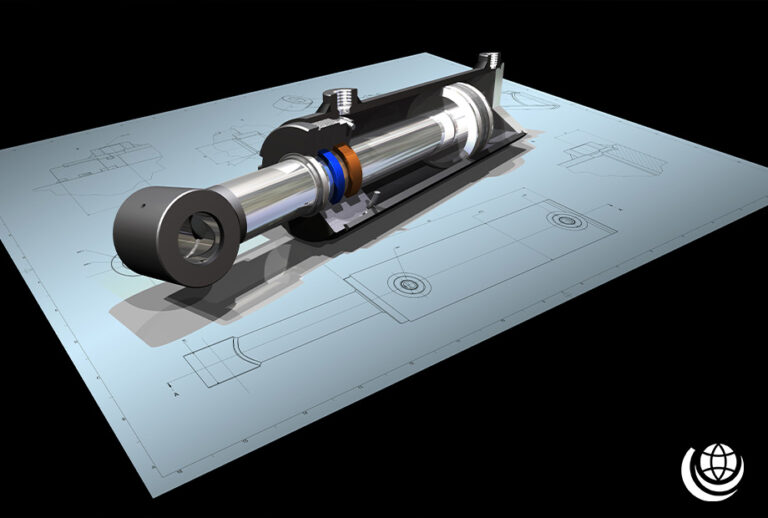

Ultimate Guide to Hydraulic Cylinders

Often called the ‘muscles’ of hydraulic systems, cylinders transform fluid power into precise linear motion—lifting, lowering, pushing, pulling, and locking heavy loads with ease.

This guide explores how they work, the different types available, and what to consider when specifying or maintaining them.

Learn MoreThe Vital Role of Hydraulic Cylinder Seals

Hydraulic cylinder seals are essential to system performance -keeping fluid contained, pressure stable, and components protected. But even the most robust seals can fail if operating conditions aren’t right.

This guide explores how seal failure happens, what to watch for, and how to prevent costly damage across demanding applications.

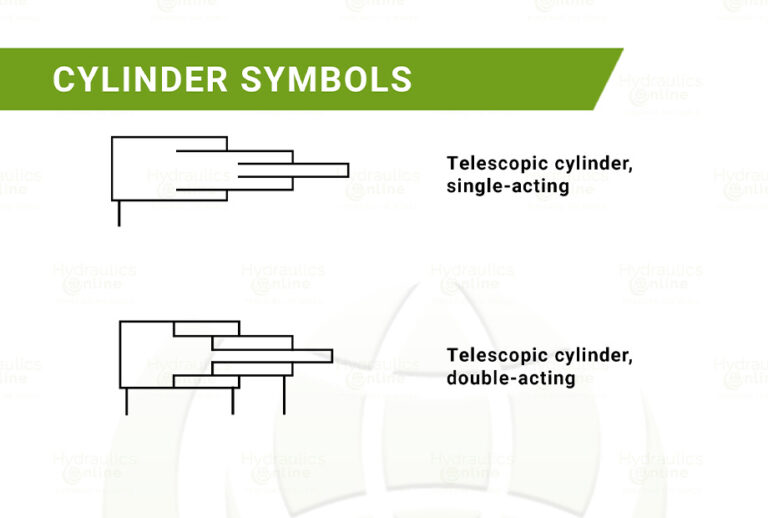

Learn moreLearn about Hydraulic Cylinder Symbols

Hydraulic cylinders play a critical role in fluid power systems, and each type has its own symbol in technical drawings.

This PDF breaks down the most commonly used cylinder symbols – helping you navigate schematics with confidence and accuracy.

Download pdf