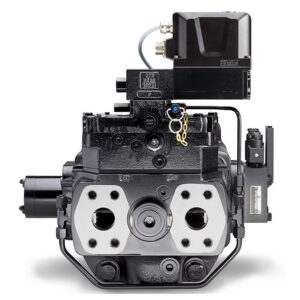

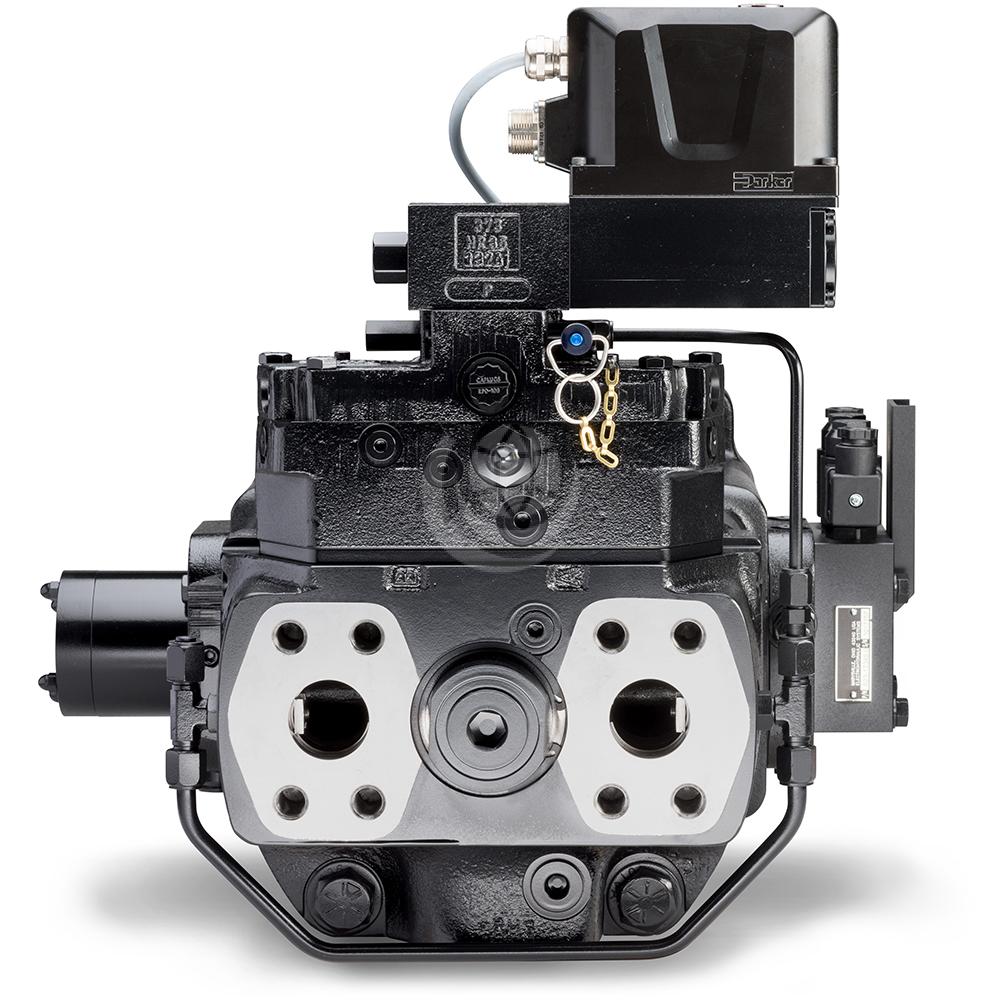

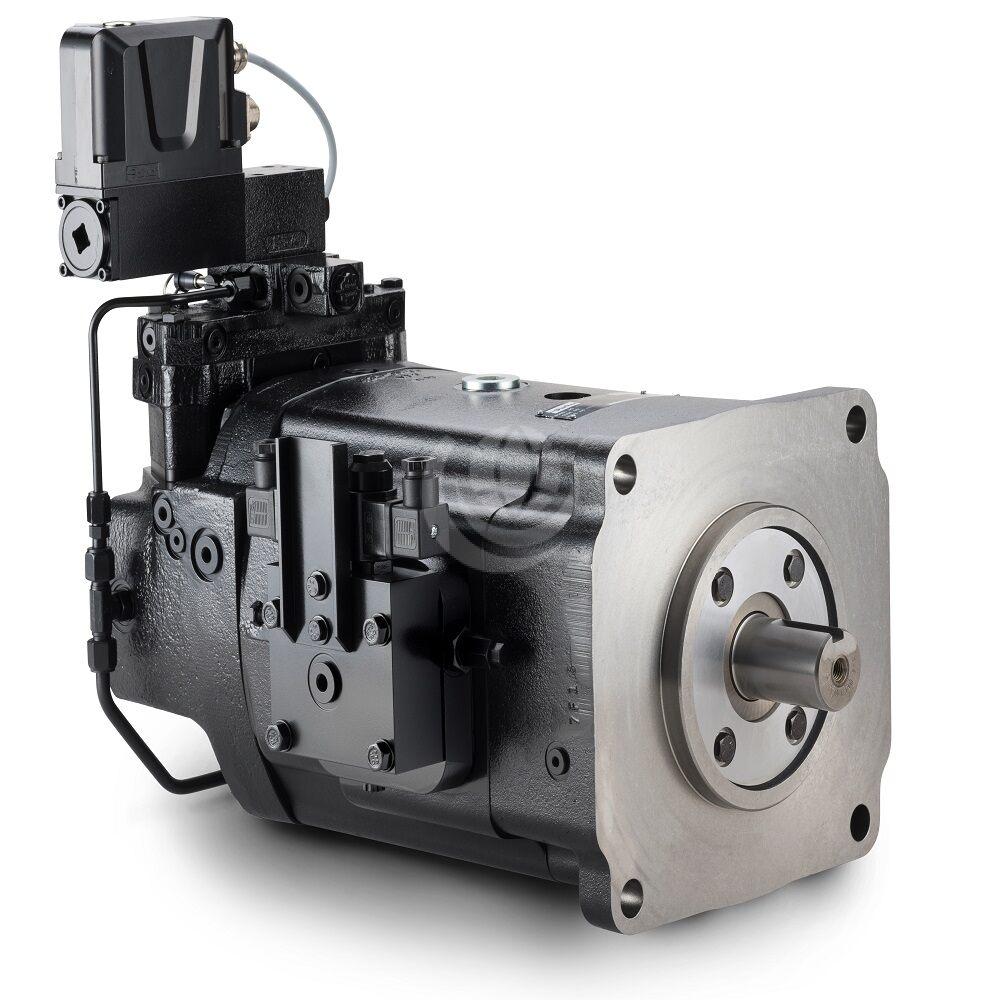

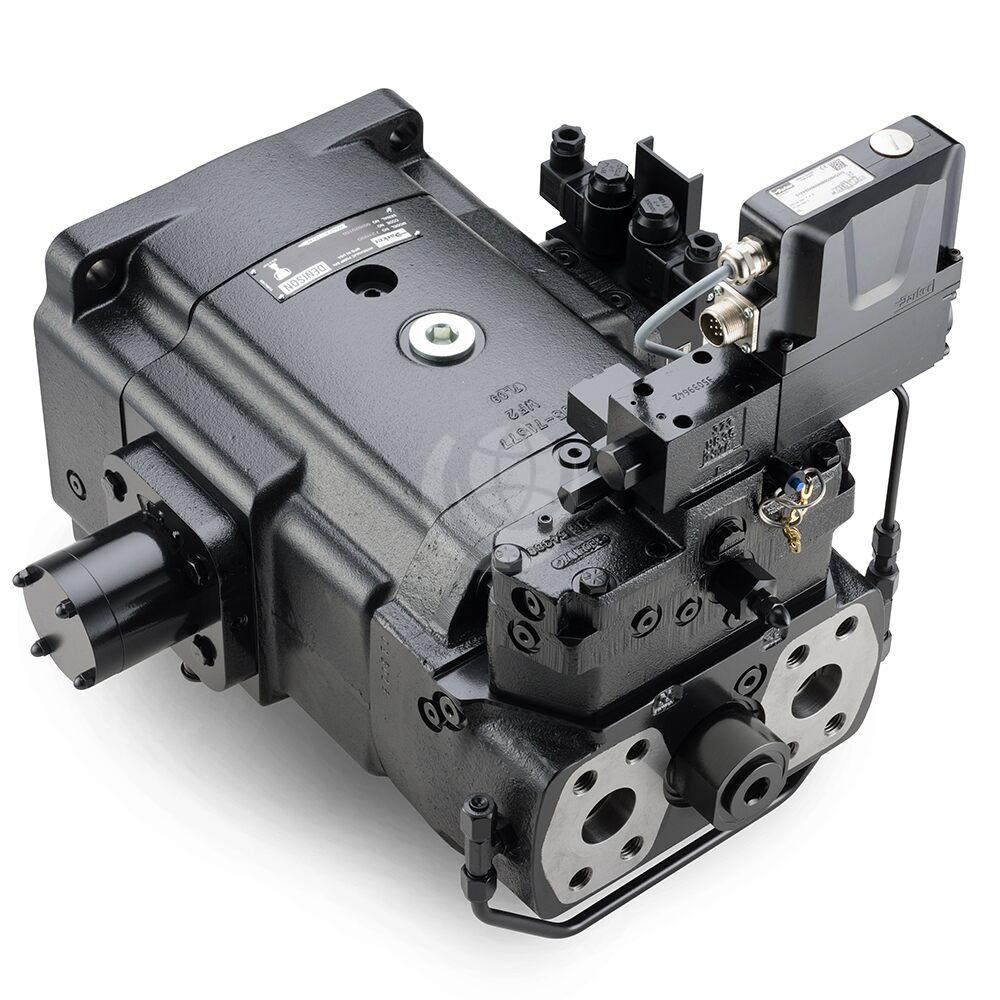

Parker Denison, formerly Denison Hydraulics, is a leading industrial manufacturer providing highly engineered hydraulic fluid power systems.

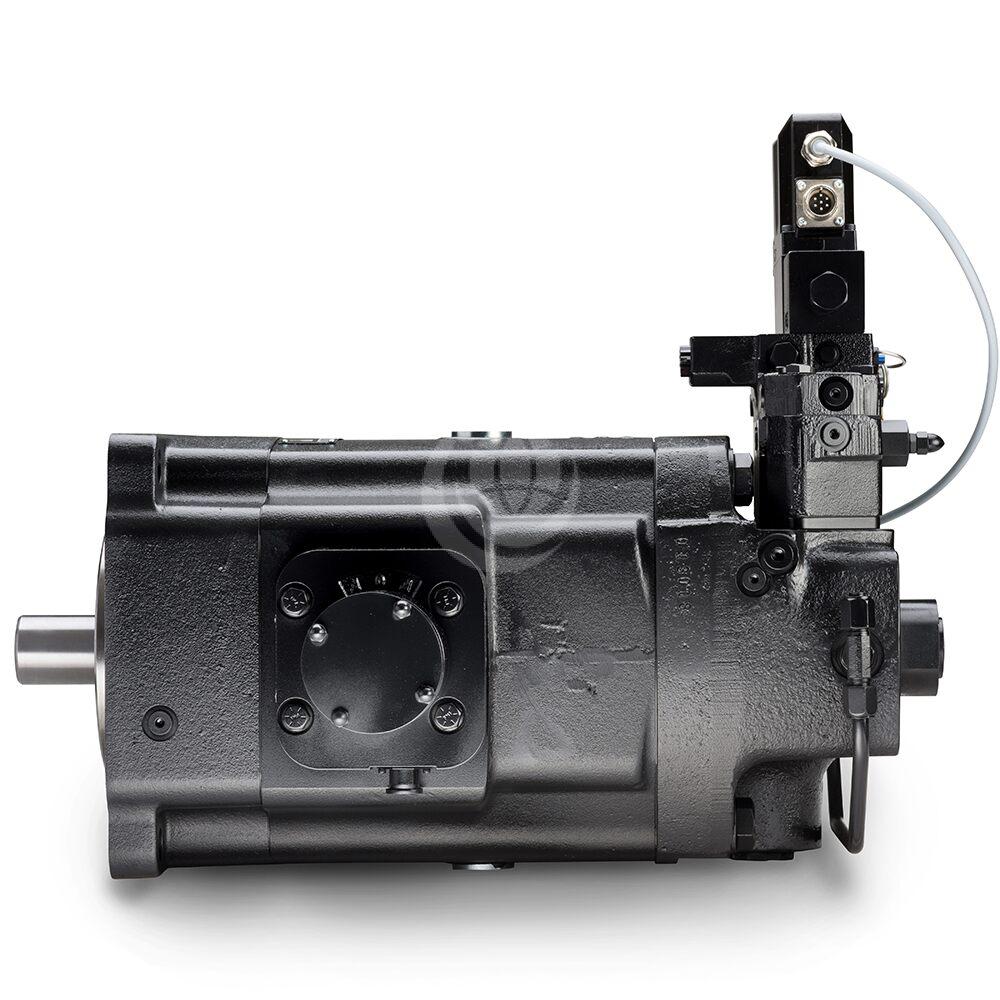

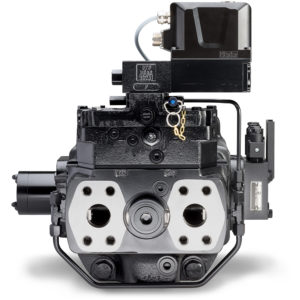

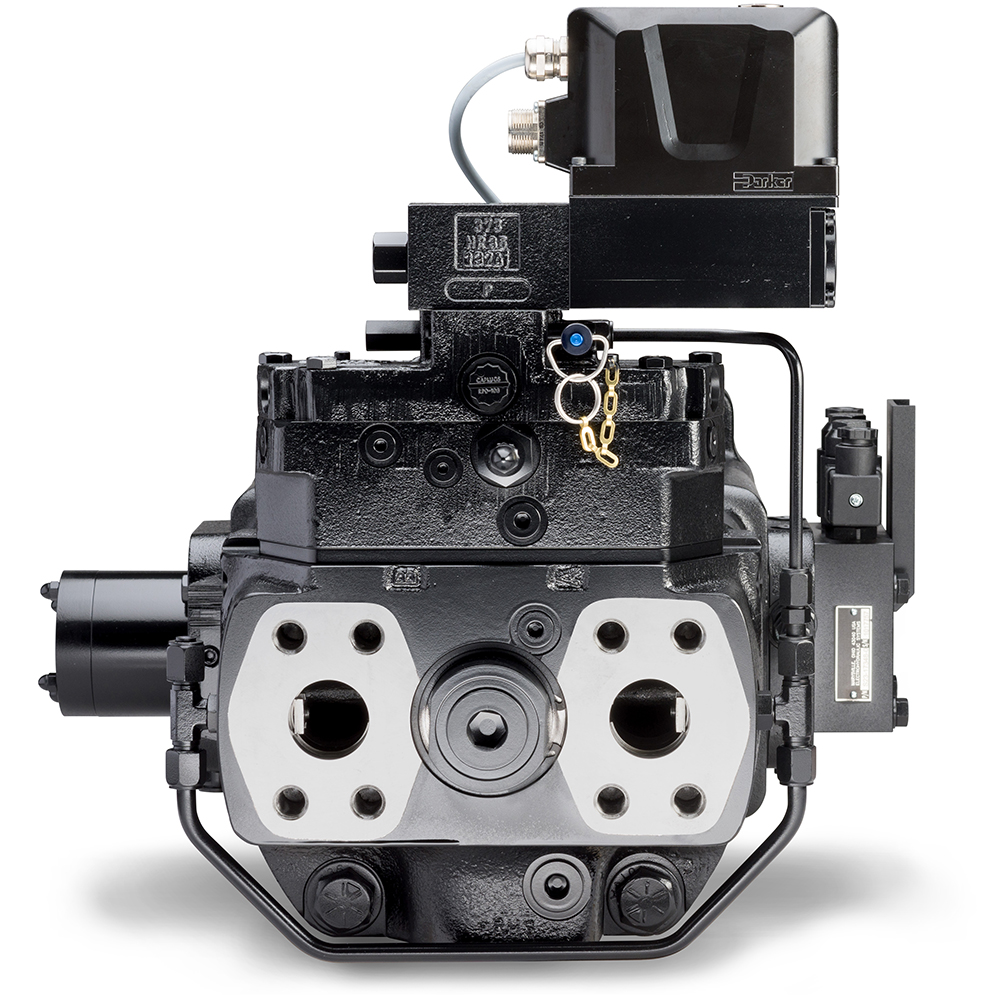

Recognised for their exceptional performance, Denison Hydraulic pumps, motors and valves are the equipment of choice in some of the harshest environments around the world. Parker Denison are also well-known for their large hydraulic piston pumps, offered under their Gold Cup and Premier Series brands.

Denison hydraulic pumps have a multitude of applications, ranging from: construction mobile equipment, demolition, agricultural, mining and utilities industries. In addition the pumps can be used in industrial manufacturing and marine equipment.

Meanwhile, Denison valves are used in a variety of commercial settings, including: injection moulding, metal and material forming, mobile crane equipment, and marine systems, such as ship-mounted winches. They are one of the few hydraulic manufacturers of flange-mounted pressure control valves. The design enables the valve to attach directly to another hydraulic component. This is in contrast to more traditional valve designs, where the associated hydraulic components connect using hydraulic lines. The latter is more expensive and less effective at controlling leaks than flange mounting.

Please contact us for further technical guidance or if you cannot see the Parker Denison hydraulic equipment that you need – we’ll be happy to help!

Parker Denison Hydraulics Product Range

Parker Hydraulics News and Insights

Subscribe to our newsletter to receive more free technical guides, product insights and resources…

Get in Touch

"*" indicates required fields