Description

Parker Drive Controlled Pumps – Parker DCP pumps – are variable-speed hydraulic pump systems which provide high energy efficiency. They provide speed-controlled, full-system solutions that are tailored exactly to a predefined circle in advance. They provide high energy efficiency, reduced noise emissions and lower component costs.

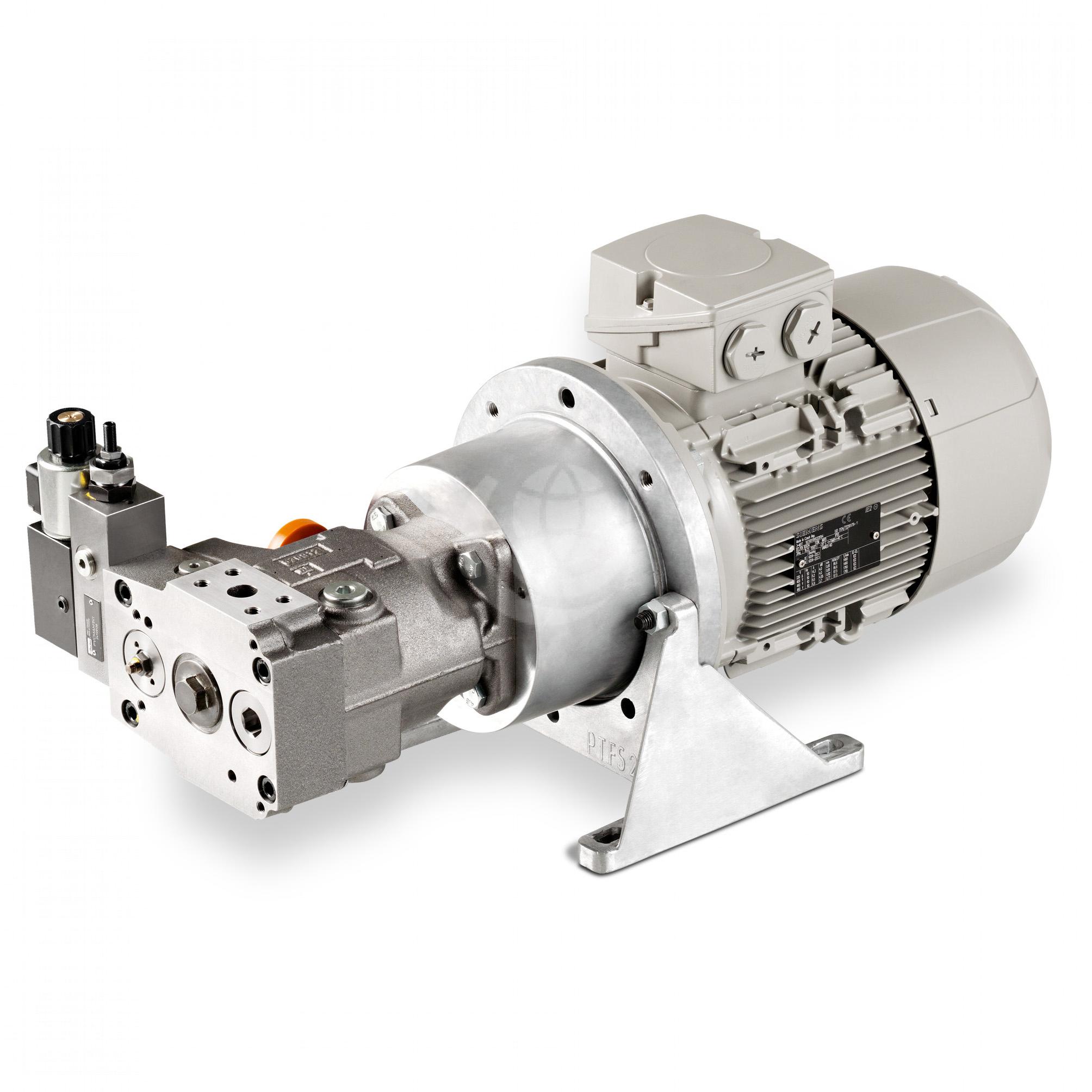

Parker DCP pumps essentially consist of three components:

- an AC drive unit (frequency controller and electronics)

- an asynchronous or synchronous motor

- a hydraulic pump.

The pump can be either a vane pump – in single or multiple design – or a variable displacement axial piston pump.

DCP pumps enable the central, regulated hydraulic supply of all drives. Thus they provide the exact power that is required in the cycle at all times.

Features and benefits include:

- Less motor and cooling power required – ensures significant energy savings

- Speed reduction at partial load – reduces noise emissions, increases component lifetime

- Smaller components with higher energy density – reduces investment costs

- Optimum adjustment to cycle requirements – higher precision and dynamics

Download the Parker DCP Brochure >>>

Contact us for further technical details and configuration options.