Hydraulic fluid contamination is responsible for the majority of system failures, making contamination control essential for optimal performance and longevity.

In this article, the first in a series produced in collaboration with Ikron, we explore the three main types of hydraulic fluid contamination and their impact on system reliability.

Contaminants in hydraulic systems are categorised into three primary types:

- Solid contaminants (particles and debris)

- Liquid contaminants (water and other fluids)

- Gaseous contaminants (air and other entrapped gases)

This classification serves as a critical first step in contamination analysis, helping to identify the likely source of hydraulic oil contamination and guide appropriate corrective actions.

Solid Contamination

Maintenance Activities

Improper maintenance practices can introduce abrasive substances into hydraulic fluid:

- Component replacements, disassembly, and reassembly may introduce contaminants if performed without proper cleanliness.

- Fluid refilling or replacement can allow foreign particles to enter if not executed with precision.

Ensuring rigorous contamination control across manufacturing, operation, and maintenance is crucial for system longevity and optimal performance.

Liquid Contamination in Hydraulic Fluid

Among the various forms of hydraulic fluid contamination, water is the most common and can significantly impact system performance.

How does water enter the system?

Water infiltration can occur through multiple pathways, including:

- Improper oil tank storage, allowing moisture accumulation.

- Leaks in water/oil heat exchangers, introducing unwanted fluids.

- Condensation, forming in storage tanks and hydraulic reservoirs due to temperature fluctuations.

- Ventilation system exposure, where water vapour enters through unprotected openings.

- Moisture absorption through cylinder rods, particularly in humid environments.

- Cross-contamination, from liquids used in machine cleaning processes.

Effects and Acceptable Limits

The risk of hydraulic fluid contamination is especially high in machines operating in humid conditions or utilizing water-based substances in their processes. While trace amounts of dissolved water may have minimal impact, excessive moisture can degrade fluid properties, accelerate component wear, and lead to system failure.

For reference, an upper limit of 300 PPM (parts per million) is generally acceptable to maintain system reliability.

Gaseous Contamination in Hydraulic Fluid

Among the various forms of hydraulic fluid contamination, air intrusion is a common issue that can affect system performance.

Dissolved Air in Hydraulic Fluids

Under normal conditions, hydraulic fluids contain dissolved air at the following approximate percentages:

- 3–4% in glycol-water mixtures

- 5–6% in water-oil emulsions

- 7–9% in synthetic fluids

- 8–10% in mineral oils

These levels can increase due to several factors, including:

- Pump suction line leaks, allowing air ingestion.

- Faulty seals, enabling air penetration into the system.

- Low oil levels, exposing fluid to excessive aeration.

- Filling and maintenance activities, inadvertently introducing air.

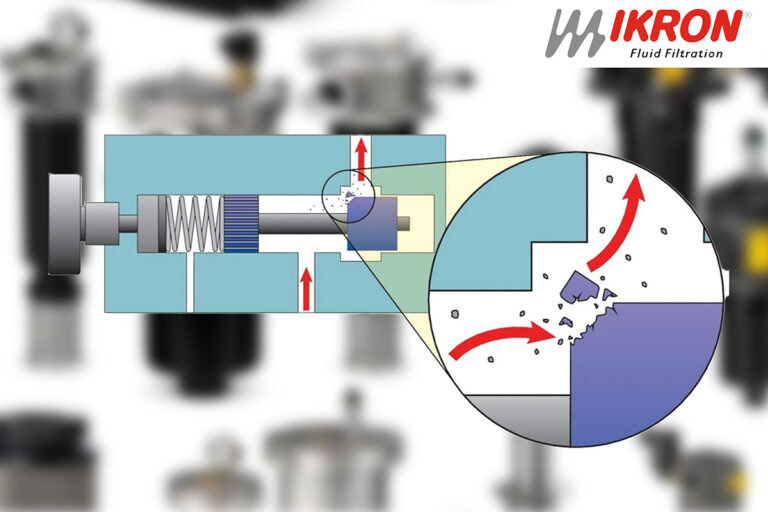

Impact of Air Contamination

Excessive gaseous contamination can lead to cavitation, foaming, and reduced lubrication efficiency, ultimately compromising hydraulic system reliability.

We are the first choice for customers in over 130 countries worldwide, supplying a vast selection of hydraulic brands and components. You are guaranteed impartial, technical advice and optimal solutions. Every time.

Discover more Free Educational Content from our Fluid Power Technical Knowledge Hub…

Hydraulic Contamination Causes and Effects

Hydraulic contamination causes up to 70% of hydraulic system failures, making it a key challenges in fluid power management. But how do contaminants form, infiltrate hydraulic systems, and lead to such widespread failure?

In this article, produced in collaboration with Ikron we explore how contaminants enter systems and impact performance.

Learn MoreThe Ultimate Hydraulic Oil Guide

Hydraulic oil is one of the most common fluids found in a hydraulic system and it is crucial that it is regularly checked and maintained. There are also many different types of available and it is important to choose the right oil for your system.

Learn MoreAn Introduction to Hydraulic Pressure and Flow

Understanding of the key principles of fluid dynamics is, essential for anyone who wishes to build or maintain hydraulic systems. One of the first concepts to understood is how the movement of fluids is quantified, namely flow.

Learn More