Hydraulic oil is one of the most common fluids found in a hydraulic system and it is crucial that it is regularly checked and maintained.

Hydraulic oil is one of the most common fluids found in a hydraulic system and it’s imperative that it’s regularly checked and maintained.

Hydraulic oil features and functions:

- Viscosity: how well the fluid flows in certain temperatures;

- Low temperature fluidity: ease of flow under low temperatures;

- Thermal and oxidative stability: preventing contamination through a sludge build-up;

- Hydrolytic stability / water tolerance: preventing contamination through water;

- Cleanliness and filterability: regular maintenance ensures reduced contamination;

- Demulsibility: ability of the component to filter out water from the oil;

- Anti-wear features that improve the life of components;

- Corrosion control: preventing corrosion of the components;

- Biodegradability and managing environmental impact.

What does hydraulic oil contain?

Hydraulic oil includes mineral oil and esters. The latter is a carbon-based compound, which is created by substituting the hydrogen of an acid with an alkyl. Other main elements in hydraulic oil include: glycol, silicone and ethers. The latter is a highly flammable, volatile liquid containing an oxygen atom which links two alkyl.

Other chemical additives are added to most hydraulic oils in order to maintain or improve the performance of both the oil and the equipment within the hydraulic system. They can prevent corrosion, rusting and also water contamination. It is vitally important to always choose the appropriate oil for your system. In fact, the wrong oil can cause performance issues and in more severe cases, permanent damage to your system and components.

When oil should be avoided

Most hydraulic components and systems use oil-based hydraulic fluids. There are, however, circumstances when oil should be avoided. For example in applications with potential ignition sources; sparks, open flames, hot metal. In such hazardous environments, a leak from a high-pressure hydraulic system could create an explosion or a serious fire. The term “ATEX” comes from the French “atmosphere explosibles” and is the name commonly given to the framework for controlling explosive atmospheres.

Which type of oil should be used?

There are many different types of oil for a wide range of applications and it is important to choose the right oil for your system.

There are three main groups of equipment and areas that hydraulic oil can be found in: mobile, industrial and aviation. Each one of these requires different types of hydraulic oil depending on the conditions they are operating in and the demands placed on the equipment.

Hydraulic oil for low temperatures

There are many different oils for applications that are utilised in harsh, cold environments. Moreover, anti-freeze additives are often added to the oil to ensure it doesn’t freeze.

Heat-resistant hydraulic oil

If the temperature of oil is increased it has a lower viscosity, meaning the oil will flow easier. This increases the risk of leaking of the loss of the oil’s properties. In the event that the system is exposed to high temperatures additives are added to the oil in order to maintain a viscosity suitable for the system.

Oil for high pressures

If oil is placed under a large amount of stress in high pressure conditions, it still needs to be able to function and enable a hydraulic system to run smoothly. This is where heavy-duty oil is necessary, usually containing additives that prevent wear. These types of hydraulic oil can be found in a wide range of applications including those used in the construction industry.

Environmentally-friendly oil

Some applications may pose a potential risk of oil spills or leaks. This could lead to environmental contamination. And therefore, most environmentally-friendly oils are biodegradable and comprise of rapeseed and other vegetables oils.

Hydraulic Oil Viscosity

The hydraulic oil viscosity depends on how smoothly it flows. For example, if viscosity increases, then it will take longer for the oil to pass through the hydraulic system. Moreover, high viscosity means the oil is thicker and is more difficult to transport through a system. On the other hand, lower viscosity means the oil is easier to pass through the system.

The measurement of viscosity in hydraulic oil is taken in Centistokes (cSt) and most commonly at temperatures of 40°C and 100°C.

Viscosity and temperature

Hydraulic oil viscosity is vital when choosing the right hydraulic oil for your system. In hydraulics, there’s a direct relationship between hydraulic oil viscosity and its temperature. For instance, if the temperature of the oil increases then the viscosity decreases. Similarly, when you put cooking oil into a pan and heat it up, the oil moves faster the longer it is heated. A temperature drop makes the oil move less easily and it becomes more viscous.

Hydraulic oil viscosity needs to be able to work effectively to enable smooth operation no matter the temperature. This is particularly important as applications become more demanding.

Viscosity index

The viscosity index helps us to measure the change in temperature in hydraulic oil. A lower viscosity index means that the oil may be more susceptible to change than if it were a higher viscosity index. Moreover, if the viscosity is high, the oil will be better suited to an application which is used in harsher environments, exposed to a variety of operating temperatures.

The viscosity must be accurate for your application and the temperature. This is true even if the oil has properties include anti-wear, anti-oxidisation or anti-corrosion. An incorrect viscosity could result in damage to hydraulic equipment, problems during operation and reduced service life.

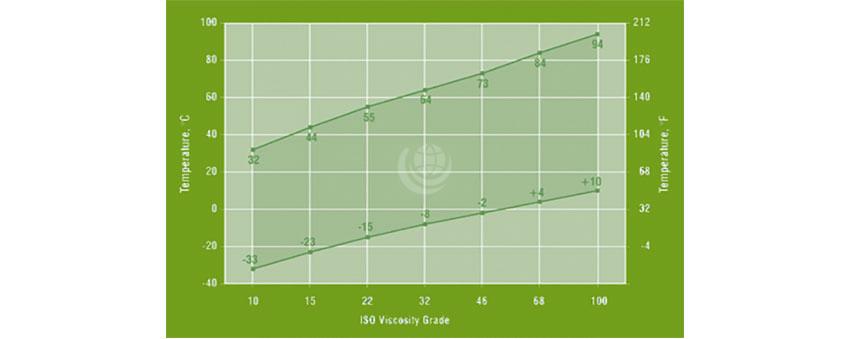

The table below shows the classifications of viscosity against different temperature ranges:

Pumps and viscosity requirements

Different pumps require different viscosities. There are three main types of pump that can be found within a hydraulic system: vane pumps, piston pumps and (internal and external) gear pumps. Each pump is utilised in different ways for different applications.

Vane Pumps

There are rotors inside vane pumps that include slots attached to a shaft that is rotating erratically to a cam ring. When in operation, the vanes can wear out, due to the constant contact between two surfaces. Because of this, vane pumps are usually less cost-effective when it comes to maintenance, however they are useful for keeping a stable flow. Vane pumps work best with viscosities ranging between 14 to 160 centistokes (cSt) at normal operating temperatures.

Piston pumps

Piston pumps are more suited to harsh conditions. They are manufactured for durability and are able to operate at higher pressures, usually up to 6,000 psi. Piston pumps work best with viscosities ranging between 10 to 160 centistokes (cSt) at normal operating temperatures.

Gear Pumps

Although gear pumps are classed as the most inefficient out of all of the pumps, they are still able to function through a large amount of contamination. They work by expelling fluid once it has been pressurised between the meshing teeth in the pump. Gear pumps come in two variations: internal and external.

Internal gear pumps are usually available in a variety of viscosities, ranging up to 2,200 cSt. With high efficiency and reduced noise, these pumps typically operate under pressure from 3,000 – 3,500 psi.

Although external gear pumps are less proficient than there counterpart, they still offer easy maintenance, stable flow and are cost-effective when it comes to purchasing and repairs. Similarly to the internal gear pumps, external gear pumps produce pressure between 3,000 – 3,500 psi – however, their viscosity range only reaches 300 cSt.

Hydraulic oil life

It’s important to maintain healthy hydraulic systems and components and there are proven methods to help you look after your hydraulic oil.

Modern hydraulic systems are typically a lot smaller and more compact than they used to be. This means that less oil is used during operation. Pumps can also produce a lot more output, subsequently producing higher pressures. Less oil within the system also means higher fluid temperatures – which in turn, increases oxidation and thermal stress on the additives on the oil. However, engineers still want the most cost-effective oils that last as long as possible and still operates faultlessly.

The hydraulic oil longevity depends on a few influences: the quality of the oil, working conditions and possibly even contamination. However, within the right environmental factors, a high quality oil should be able to last at least six months. And with the right maintenance and up-keep, the hydraulic oil life should be able to last even longer.

Oil Temperature

Hydraulic oil life can be greatly impacted by the temperature of the oil during operation. The most common temperature in most industrial applications is around 60°C. However it may fluctuate and even rise to 85°C, which is normal. If the oil temperature remains at 85°C for a long period of time, there is a risk of restricting the life of your oil, as the oxidising process is enhanced. For every 10°C that the temperature increases, the more the oxidation increases and thus, significantly reducing the hydraulic oil life.

Oxidation

Oxidation is the process of the conversion of hydrocarbon molecules in to carboxylic acids. As we’ve said before, higher temperatures can reduce the life of the hydraulic oil, as it quickens the oxidation process. The by-products made from oxidation eventually form a varnish, which subsequently can block filters and suction strainers. If oxidation becomes a big issue, changing the oil immediately is the best course of action.

Moreover, contaminants (such as water, air, dirt, fuel, and other oils or lubricants) are a common issues that can have a detrimental effect on hydraulic oil life.

How to make your oil more cost-effective

1). Ensure that any oil you have in your system is of high quality and from a supplier who can provide technical support when needed;

2). Keep an eye on operation conditions. Make sure the fluid is always kept clean;

3). Always ensure oil is changed if oxidation or contamination become too much.

Whilst there are ways the user can help preserve oil life, there are also various methods of ensuring long hydraulic oil life within the oil itself. For instance the usage of additives. The additives used in the oil are dependent on what the oil is used for in the system. This allows the oil to perform in diverse conditions.

- Anti-wear: lengthens the service life of hydraulic components and machinery;

- Cold flow: these additives enable a system to operate in extremely cold environments;

- Anti-foaming: an anti-foaming agent for hydraulic oil reduces foaming within the fluid which is sometimes caused by detergents. This foaming can reduce the lubricating quality of the product thus causing damage;

- Anti-oxidant: allows for longer periods of use without an oil change and also reduces sludge deposits;

- Anti-rust: forms a protective coating which reduces the risk of rust damage from oxygen contact.

Hydraulic filters and oil life

A hydraulic filter is an essential component of any hydraulic system. Moreover, selecting the right hydraulic filter is absolutely vital to protect oil life and ensure that particle contaminants are removed from the hydraulic fluid before components are jammed or damaged through abrasive wear.

We have widespread, competitive access to both leading and niche hydraulic filtration equipment manufacturers from around the world, including ATEX approved – “explosion proof”– hydraulic filtration components.

We’re a hydraulics ‘hub’, offering thousands of possibilities… how can we help?

Expand your Hydraulic Knowledge with more content from our Fluid Power Technical Knowledge Hub…

Hydraulic System Contamination

Hydraulic system contamination is responsible for 80% of system failures – whether through the introduction of contaminated fluid or more progressively through, for example, metal surface wear, corrosion or cavitation.

In this article, produced in conjunction with MP Filtri, we look at the effects of each, best practice for prevention and how best to remove contaminants already in your system.

Learn More

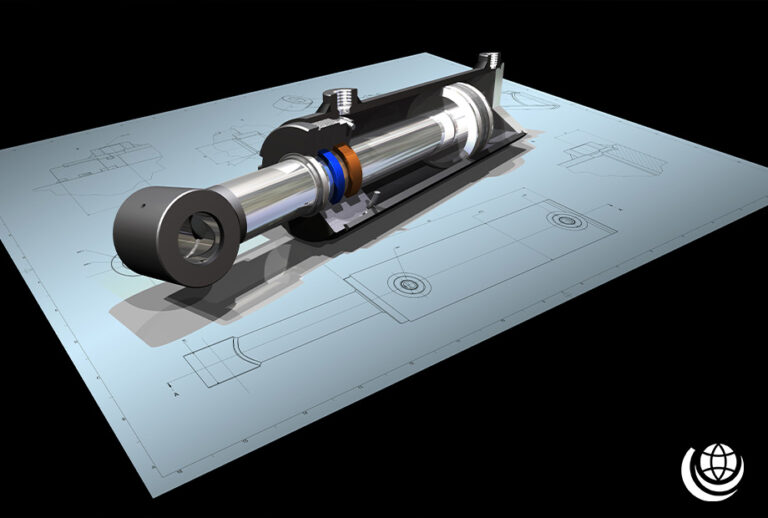

The Vital Role of Hydraulic Cylinder Seals

Hydraulic cylinder seals are far from the boring components they seem to be, performing a vital task within all hydraulic cylinders.

Despite their durability, seals can however fail or cause serious damage if the settings are not correct. Oil contamination, high temperature, chemical erosion or inadequate installation can all cause hydraulic cylinder seals to fail leading to damage in the wider system.

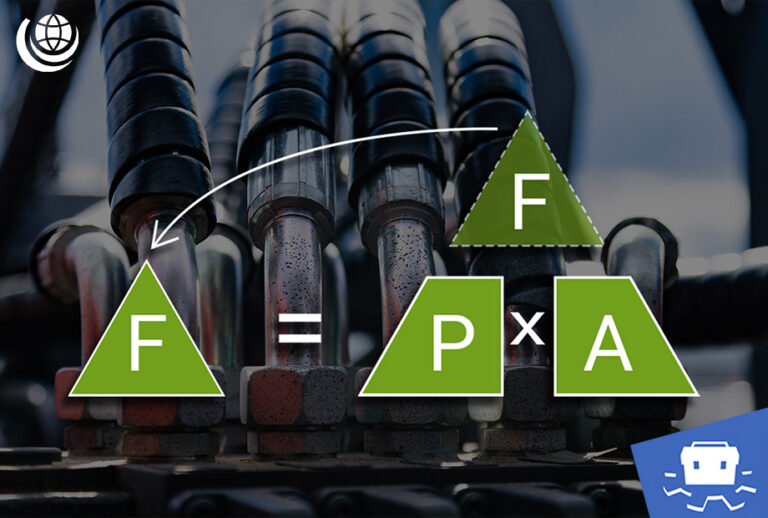

Learn MoreAn Introduction to Hydraulic Pressure and Flow

An understanding of the key principles of fluid dynamics is essential for anyone who wishes to build or maintain hydraulic systems.

In this article, we will consider the key concepts of pressure and flow and how they apply to hydraulic systems – as it is the pressure and flow which enable work and motion to be accomplished.

Learn More