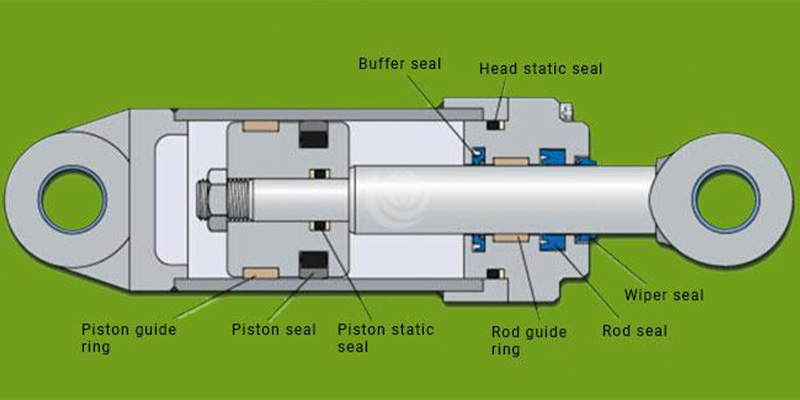

Hydraulic cylinder seals are essential components in any hydraulic system, playing a critical role in converting fluid power into controlled linear motion.

Hydraulic cylinder seals are found in a wide range of applications where components are exposed to pressurised liquids, these seals ensure that hydraulic fluid remains contained – preventing leaks, maintaining pressure, and protecting internal components from contamination.

Manufactured from durable materials such as rubber and polyurethane, hydraulic cylinder seals are designed to withstand extreme operating conditions. However, even the most robust seals can fail if system parameters are not properly maintained. Common causes of seal failure include:

- Oil contamination

- Excessive heat

- Chemical erosion

- Improper installation

When hydraulic cylinder seals fail, the consequences can be severe – ranging from reduced system efficiency to catastrophic equipment damage. That’s why proper seal selection, installation, and maintenance are vital to the long-term performance of any hydraulic system.

Read on to explore these common hydraulic seal failure modes in more detail – including how to identify early warning signs and prevent costly downtime.

Oil Contamination

One of the leading causes of hydraulic cylinder seal failure is oil contamination within the system. Contaminated hydraulic fluid can compromise seal integrity, increase internal leakage, and reduce the precision of flow and pressure control in valves. Over time, this inefficiency can lead to wasted horsepower, reduced system performance, and even overheating.

Contaminants can enter the hydraulic system from multiple sources, including:

- Hydraulic oil itself – if not properly filtered or maintained

- Environmental exposure – such as dust, dirt, or moisture entering the system

- System wear – metal particles or debris from internal component degradation

- Manufacturing or servicing residues – leftover particles from assembly or repairs

- Rod retraction – drawing in contaminants from the external environment

To mitigate these risks, it’s essential to install a rod wiper – a component specifically designed to prevent external contaminants from entering the cylinder as the rod retracts. Additionally, using high-quality filtration systems and regularly monitoring oil cleanliness can significantly extend the life of your hydraulic cylinder seals.

Signs of contamination-related damage include:

- Scratched rods or cylinder surfaces

- Excessive or uneven seal wear

- Visible oil leaks around the cylinder

If any of these symptoms appear, it’s critical to inspect and clean the hydraulic oil immediately to prevent further damage to the system.

Excessive Heat

Another major factor contributing to hydraulic cylinder seal failure is excessive heat. When hydraulic oil temperatures rise beyond the seal’s material tolerance, the seals can become hard, brittle, or begin to erode – especially at the lip or body. Prolonged exposure to high temperatures can cause the seal to lose its elasticity and structural integrity, ultimately leading to leakage or complete failure.

Common signs of heat-related seal damage include:

- Hardened or cracked seal surfaces

- Brittle texture or flaking edges

- Erosion or melting of the seal lip or body

This type of failure can occur for several reasons:

- Incorrect seal material – not rated for the system’s operating temperature

- Excessive friction – from poor lubrication or misalignment

- Proximity to heat sources – such as engines, pumps, or external radiant heat

To prevent heat-related damage, it’s essential to:

- Select temperature-resistant seal materials (e.g. Viton, PTFE, or high-grade polyurethane)

- Ensure proper lubrication and alignment to reduce friction

- Use thermal shielding or reposition components away from heat sources when possible

Monitoring oil temperature and choosing seals designed for your system’s thermal environment are key to maintaining long-term performance and avoiding costly downtime.

Chemical erosion

Chemical erosion is another critical factor that can compromise the performance and lifespan of hydraulic cylinder seals. When seals are manufactured from materials that are incompatible with the hydraulic fluid or its additives, a chemical reaction can occur – leading to degradation of both the seal and the fluid itself.

This chemical breakdown can result in:

- Loss of seal lip integrity – reducing the seal’s ability to contain pressure

- Excessive swelling or shrinkage – altering the seal’s fit and function

- Discolouration – a visible sign that the seal material is reacting with the fluid

Incompatible materials may also accelerate the breakdown of the hydraulic oil, altering its chemical composition and reducing its effectiveness. This creates a feedback loop where degraded oil further damages seals, and vice versa.

To prevent chemical erosion:

- Always select seal materials compatible with your hydraulic fluid (e.g. Nitrile for petroleum-based oils, Viton for aggressive fluids)

- Review fluid additive packages to ensure they won’t react with seal compounds

- Regularly inspect seals for early signs of chemical attack, such as softening, cracking, or colour changes

Choosing the right material for your hydraulic cylinder seals is essential – not just for performance, but for the chemical stability of the entire system.

Inadequate cylinder seal installation

Even the highest-quality hydraulic cylinder seals can fail prematurely if they are not installed correctly. Inadequate installation is one of the most common – and preventable – causes of hydraulic system failure.

Proper installation requires real attention to detail. Key factors to consider include:

- Cleanliness: All components must be thoroughly cleaned before installation to prevent contamination and abrasion

- Seal handling: Avoid scratching, nicking, or overstretching the seal during installation. Even minor damage can compromise performance

- Lubrication: Ensure the entire system is properly lubricated to reduce friction and ease seal insertion

- Correct fit: The seal gland must not be too tight, and no part of the gland should obstruct the seal lip

- Orientation: Installing a seal upside down is a surprisingly common error – always double-check orientation before final assembly

Improper installation can lead to immediate issues such as leakage, pressure loss, or accelerated wear. In the long term, it can cause damage to the cylinder rod, housing, and other critical components.

To avoid these pitfalls, always follow manufacturer guidelines, use the correct tools, and inspect seals carefully before and after installation. A few extra minutes of care can save hours of costly downtime.

We’re a 'truly integrated hydraulics supplier', offering thousands of possibilities, trusted by customers in 130 countries worldwide… how can we help?

Learn more about Hydraulic Cylinders in our Fluid Power Technical Knowledge Hub….

Ultimate Guide to Hydraulic Cylinders

Often called the ‘muscles’ of hydraulic systems, cylinders transform fluid power into precise linear motion—lifting, lowering, pushing, pulling, and locking heavy loads with ease.

This guide explores how they work, the different types available, and what to consider when specifying or maintaining them.

Learn MoreSafe Hydraulic Cylinder Storage

Prevention is better than cure -especially when it comes to hydraulic cylinders.

This guide shares essential tips to help you store cylinders safely and protect against corrosion, contamination, and costly downtime.

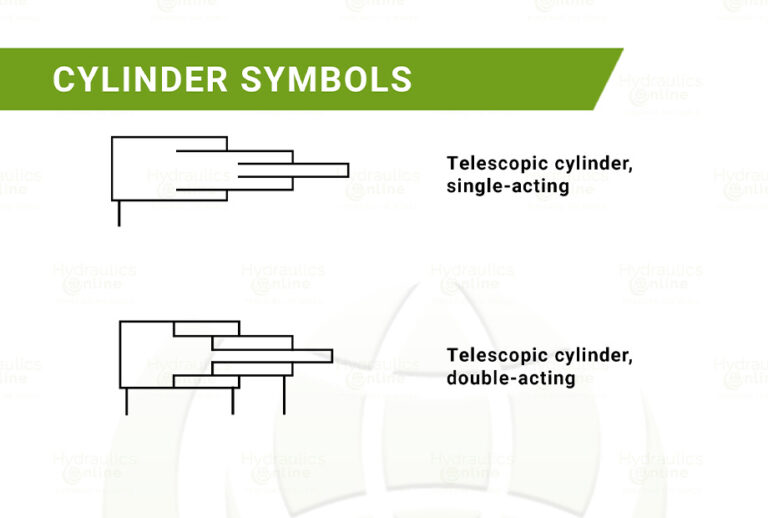

Learn moreLearn about Hydraulic Cylinder Symbols

Hydraulic cylinders play a critical role in fluid power systems, and each type has its own symbol in technical drawings.

This PDF breaks down the most commonly used cylinder symbols – helping you navigate schematics with confidence and accuracy.

Download pdf