Smarter hydraulic pump drive systems offer a range of benefits for industrial applications

Including enhanced energy efficiency, advanced controllability, system versatility, and superior noise and vibration control. Discover how switching to modern pump drive technologies can elevate performance, reduce downtime, and future-proof your operations.

Smart Hydraulic Pump Drive Systems: Meeting the Demands of a Smarter Market

To stay ahead in today’s hydraulic market, upgrading to intelligent hydraulic pump drive technology is no longer optional – it’s essential. Smarter systems enable dynamic control, adaptive performance, and real-time responsiveness, reshaping how industrial machines operate.

Why Intelligence Matters in Hydraulic Systems

- Modern components do more than execute commands – they optimise performance in real-time

- Adaptive drives allow precision control, reduced energy consumption, and improved machine diagnostics

- OEMs are being pushed to adopt smarter designs as end-user expectations rise

In a landscape where “smart” quickly becomes obsolete, innovation is a moving target. Industrial buyers are seeking systems that aren’t just functional – they’re future-ready. That’s why hydraulic pump drive upgrades must centre around intelligence, integration, and efficiency.

Original Equipment Manufacturers should consider at least four main issues when considering a switch to a “smarter” hydraulic pump drive system for their equipment

Reason 1: Efficiency – More Output, Less Input

In today’s performance-driven landscape, “just working” isn’t enough. Smarter hydraulic pump drive systems deliver higher efficiency, enabling machines to complete tasks faster, with less energy, and at reduced operating costs.

What Makes Them More Efficient?

- On-demand power delivery adjusts flow and pressure based on real-time demand – cutting waste

- Energy savings from reduced throttling and heat buildup

- Lower operational costs thanks to better fluid management and extended component life

If your current setup struggles to balance power with productivity, upgrading your hydraulic pump drive can be a game-changing move toward leaner, smarter operation.

Reason 2: Controllability – Precision Power for Every Process Stage

A major leap forward with smart hydraulic pump drive systems is the ability to precisely control every aspect of hydraulic performance. Through strategically placed sensors and intelligent feedback loops, modern pumps can deliver exact flow and pressure tailored to the task at hand.

How Smart Control Boosts Results:

- Sensor integration monitors system demand in real time

- Adaptive flow and pressure control ensures optimal performance at every production stage

- Tighter process control leads to improved product quality and consistent repeatability

- Better energy efficiency by eliminating wasteful overdelivery of fluid power

This elevated controllability transforms hydraulic systems from basic power units into responsive, efficient workhorses – perfect for applications where accuracy, repeatability, and speed all matter.

Reason 3: Versatility – Smarter Pump Drives Adapt on Demand

Not every operation calls for full-throttle performance 24/7. Smart hydraulic pump drive systems bring the kind of flexibility that allows your machinery to scale output based on real-time needs – delivering operational versatility that traditional systems simply can’t match.

Flexible Performance Advantages:

- Multi-mode operation lets pumps switch between full power, standby, and energy-saving modes

- Adaptability to changing specs or cycle stages improves responsiveness and throughput

- Optimised energy usage – only deliver what’s needed, when it’s needed

- Perfect for processes with variable load profiles, intermittent demands, or multi-tasking workflows

Whether you’re powering heavy-duty manufacturing or managing lighter, variable operations, a smarter hydraulic pump drive system adjusts without compromise – giving you power when you need it, and savings when you don’t.

Reason 4: Noise and Vibration Control – Compliance Meets Precision

Smart hydraulic pump drive systems are engineered for quiet efficiency. By reducing unwanted noise and vibration, they help meet evolving noise regulations while creating a more stable, accurate, and operator-friendly work environment.

Sound and Vibration Benefits:

- Reduced workplace noise contributes to safer, healthier conditions for employees

- Improved equipment stability leads to more precise finished products and fewer production defects

- Lower maintenance costs by decreasing wear and tear on components vulnerable to excess motion

- Helps manufacturers remain compliant with noise emission standards and site-specific acoustic limits

Noise control isn’t just about comfort – it’s about protecting people, enhancing product quality, and ensuring long-term equipment reliability. When your hydraulic pump drive system runs smooth and silent, everything else runs better too.

Smarter Hydraulic Pump Drive Systems — Automating Fluid Power with Intelligence

Modern hydraulic pump drive systems – such as the Eaton X20 series – embody the shift from brute force to smart functionality. By balancing power generation, control, and energy consumption, these systems help elevate performance while streamlining operations.

Reproduced with kind permission from Eaton Hydraulics. Authorised and regulated by Eaton. All rights reserved.

Hydraulics Online is the first choice for customers worldwide – supplying a huge range of hydraulic brands and components and guaranteeing you impartial, technical advice and optimal solutions. How can we help?

Expand your Knowledge with more Free Content from our Technical Knowledge Hub…

Selecting Hydraulic Fluid for your Hydraulic Pump

The hydraulic fluid is one of the most important components in the system yet it is often overlooked…

The fluid is the medium for the transmission of power and without sufficient fluid, no work can take place. It also performs functions such as lubrication, heat transfer and allows the conveyance of debris and contamination.

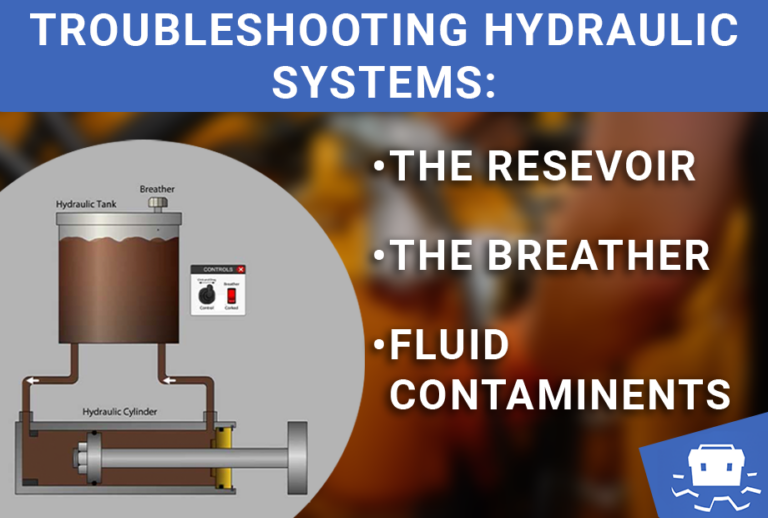

Learn MoreTroubleshooting Hydraulic Systems:

While a “fluid storage tank” might seem like a very simple concept, the design and implementation of the reservoir is very important.

The efficiency of even the most well-designed hydraulic system can be undermined by poor hydraulic reservoir design.

Learn More

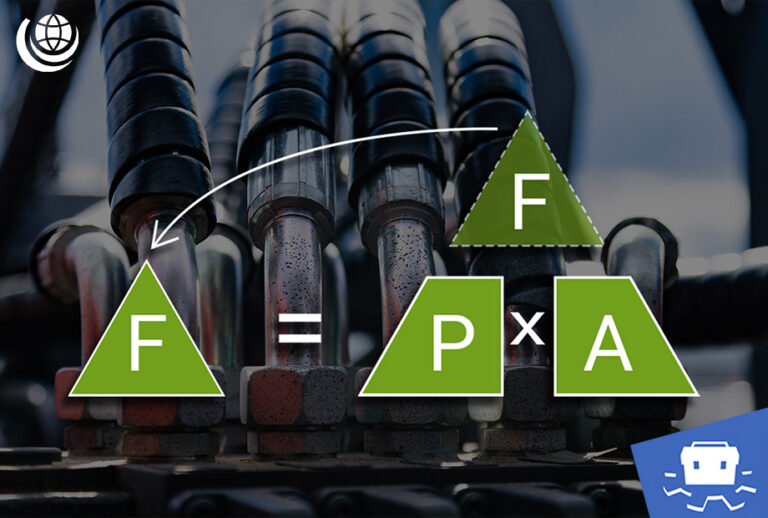

An Introduction to Hydraulic Pressure and Flow

Hydraulic systems are based on the principles of fluid dynamics; this important branch of science deals with the movement of fluids.

An understanding of the key principles of fluid dynamics is, therefore, essential for anyone who wishes to build or maintain hydraulic systems.

Learn More