Proper hydraulic equipment assembly is essential for system reliability, performance, and safety. Whether you’re building a new setup or replacing components, this guide shares practical advice to help you avoid contamination, reduce downtime, and extend the life of your system.

Why Assembly Matters

By assembling your hydraulic equipment correctly, you protect your investment and ensure optimal performance from day one. Improper assembly can lead to:

- Leaks and pressure loss;

- Component damage or premature failure;

- Contamination of hydraulic fluid;

- Reduced system efficiency and safety risks.

Follow these hints and tips to avoid unnecessary problems and system downtime when assembling your hydraulic equipment:

Prepare a Clean Workspace

Most importantly – maintain cleanliness; contamination is the reason for many hydraulic problems.

- Seal all reservoir openings after cleaning to prevent airborne debris

- Avoid grinding or welding near components. Keep cylinders, valves, hoses, and pumps capped until final installation

- Store mineral spirits in certified safety containers to reduce contamination risk

- Use dry, filtered air hoses for cleaning fittings—unfiltered air introduces moisture and debris

- Check out our guide on air contamination for more details

Pre-Install Checks and Connections

- Inspect fittings and hose assemblies – remove burrs, dirt, and scale

- Ream tubing ends to improve flow and prevent turbulence

- Avoid Teflon tape on straight thread connections – it can lead to system leaks and debris entry

Pumps, Motors and Alignment Tips

- Align coupling halves within 0.007 inch for optimal fit; use 1/32 to 1/16 inch clearance on flexible couplings per manufacturer specifications

- Never hammer or force-fit couplings – they should slide on or be shrunk with hot hydraulic oil

- Use dry spray-on lubricant on splines to prevent premature wear

- When using double universal joints, ensure shafts are parallel and yokes aligned

V-Belt Pulley Installation

- Line up pulleys precisely and install with minimal overhang – closer proximity to the pump or motor face extends bearing surface life

By following these simple yet essential tips, you can ensure your hydraulic equipment is assembled cleanly, safely, and with long-term reliability in mind. Whether you’re working on a new installation or maintaining an existing system, attention to detail during assembly helps prevent costly downtime and protects the integrity of your components. A little care at the start goes a long way.

We’re your go-to hydraulics hub – thousands of possibilities, one trusted team. How can we support you today?

Discover more Free Educational Content including more hydraulic tips and tricks from our Fluid Power Technical Knowledge Hub…

The Ultimate Hydraulic Oil Guide

Hydraulic oil is the lifeblood of any hydraulic system – essential for performance, yet often underestimated. Regular checks and maintenance are vital to avoid contamination, wear, and costly downtime.

Explore our comprehensive guide to understand what hydraulic oil does, how to choose the right type, and how to keep your system running smoothly.

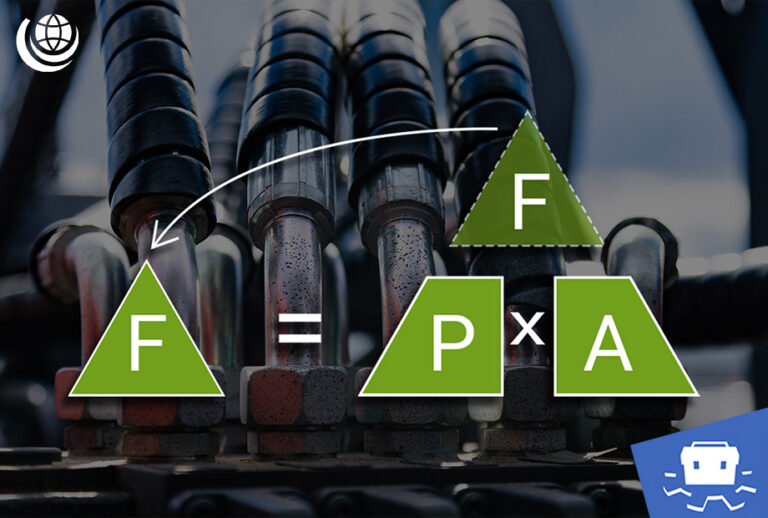

Learn MoreAn Introduction to Hydraulic Pressure and Flow

A solid grasp of fluid dynamics is key to building or maintaining hydraulic systems. This guide outlines how pressure and flow interact to drive motion, covering essential principles like laminar versus turbulent flow, Bernoulli’s Principle, and the FPA Triangle.

Whether you’re starting out or refreshing your knowledge, it’s a practical dive into the science behind fluid power.

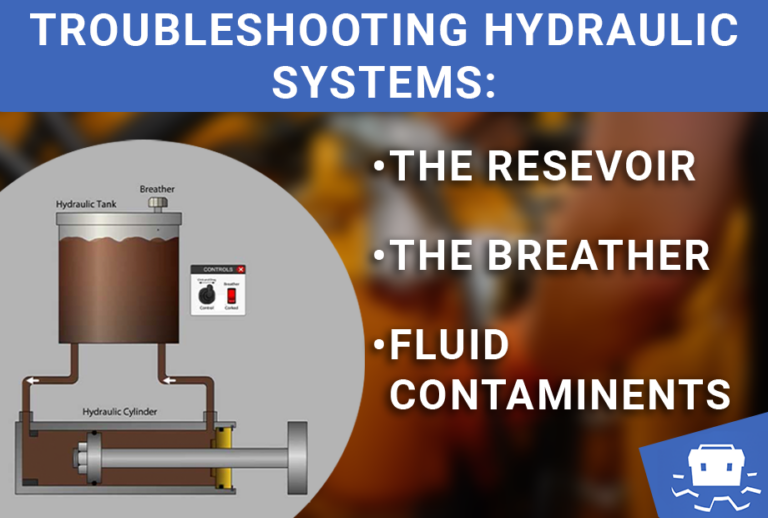

Learn MoreTroubleshooting Hydraulic Systems: The Reservoir, The Breather and Fluid Contaminents

The hydraulic reservoir does far more than store fluid – it regulates temperature, traps contaminants, and protects system integrity.

This guide explores how reservoir design, breather function, and filtration choices impact performance, and how poor implementation can lead to costly failures.

Learn More