Hydraulic actuators cause engineered equipment to move, slide, rotate and lift by converting energy from pressurised fluid and hydraulic power units. Depending on the type of machinery involved and the desired movement needed, there are a variety of linear and rotary actuators available to best match the needs of the designer.

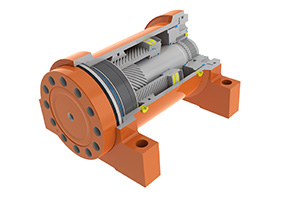

Primarily, there are two prominent groups of actuators: linear and rotary. Linear actuators are by far the most prolific and are comprised of hydraulic cylinders and rams. Rotary actuators are more specialized, including the rack and pinion style, vane type, and helical design often referred to as piston and helix. All these designs are applied to create efficient linear or rotary movement.

The keys to selecting the most appropriate design style of actuator are two-fold: first is understanding the conditions of the application, and second is having good knowledge of the unique characteristics of each actuator design.

For those who deal with heavy-duty applications, helical actuators offer greater performance and durability that is commonly needed in severe conditions and high shock applications. Helical actuators offer high power density with high output torque for maximum productivity in a compact design. Over other actuator styles, helical actuators have low maintenance requirements, high bearing capacity and feature extreme shock resistance making them a great fit for severe-duty applications.

Helical hydraulic actuators can be found in these heavy-duty motion control applications:

- Industrial dumpers

- Ferry loading ramp

- Heavy duty dump gate

- Basket, crane and concrete chute rotation

- Underground rock drills

Each of these applications requires the control of a precise movement to complete the machine’s task.

Industrial dumpers

With industrial bin dumpers, there needs to be enough force to fully invert the bin and allow for the materials to be effectively and completely discharged from the bin. By contrast, hydraulic cylinders operate under geometric constraints that do not allow 180-degree inversion of the bin meaning that contents remain lodged. Implementing dual helical actuators in line with each other gives the machine enough torque to invert the full bin in a full 180-degree arc. In this application, helical actuators can operate as the main torque transmitting device while simultaneously being the structural bearing or pivot point. This decreases the need for additional components, simplifying the arrangement and installation, and allowing machine designers to focus on other aspects of the machine.

Ferry loading ramp

A ferry loading ramp needs to be lifted into a neutral position for the ferry to sail. Achieving a neutral position requires a great amount of torque that helical actuators offer. Helical actuators for this application are implemented in tandem working together to produce the necessary torque to lift the ramp upright and prepare the vessel for sail. Upon reaching the shore, the helical actuators control the load of the descending ramp.

This is achieved by integrated dual counterbalance valves. The function of integral dual counterbalance valves (attached directly to the body of the helical actuators) work as a load-holding device or hydraulic counterbalance, hence the name.

Since the helical actuators feature zero internal leakage, they control the load against gravity without drifting. Positive, drift-free positioning is an important aspect of the actuators’ performance.

Heavy duty dump gate

For dump gates, it’s important to make sure the descending gate is lowered slowly and smoothly, so the materials are deposited in the desired location. Helical actuators are perfect for this application because they also act as mechanical, hydraulic hinges. The result is smooth action of the opening gate. Aside from the actuators doubling as hydraulic hinges for controlled motion, the integration of the actuator’s inherent bearing capacity eliminates the need for additional components such as mechanical bearings, hinges or pins.

Basket, crane and concrete chute rotation

Helical actuators mounted between the tip of the boom and basket of bucket trucks (known in the industry as MEWPs or mobile elevated work platforms) provide 2 critical functions at once: They hydraulically rotate the platform to the desired working position (usually 180-degrees or less) and hold it there without drift via the integral counterbalance (or load-holding) valve. Secondly, they act as the superstructure and support the fully loaded weight of the platform, including the weight of work personnel and their tools & equipment.

Cranes require precise positioning control to place the material where it is needed. This means the rotation of the crane needs to be smooth and slow and helical actuators provide exactly that. Again, the optional load-holding valve and zero internal leakage of the actuator provides the performance characteristics needed in crane positioning applications up to 360-degrees.

For a concrete chute to rotate effectively the machine requires two features from its actuators. The first requirement is the straddle-moment capacity, which is the actuator’s ability to fully support the mass of the chute and the load of the concrete itself. The second requirement is providing enough torque to swing the fully-loaded concrete chute, in some cases up a slight incline or grade. Helical actuators properly achieve both features for the operative use of the concrete chute.

Underground rock drills

Underground rock drills present one of the harshest, most unforgiving environments and worst conditions for engineered equipment. Drive and positioning components are chosen for their rugged characteristics, trouble-free service life and dependability.

Rock drilling machines are commonly referred to as jumbos. At the working end of the jumbos are long, twin drill booms. The booms need to rotate through 360-degrees to create the desired profile of the mine shaft. The booms rotate in a parallel, mirror-like fashion; think of how bird wings flap in opposition to each other. This symmetrical motion is created by a pair of robust helical rotary actuators. The actuators provide drift-free positioning and hydraulically lock the booms in the desired position while the drills are engaged and during drill extraction. The drill feed forces and opposing drill retraction forces are huge and these forces are supported by the helical actuators. The result is smooth, controlled positioning up to 360-degrees and the actuators are essentially a structural extension of the boom.

To create even greater value for our clients, in this application the large-diameter shafts of the helical actuators are held stationary and mounted directly to the end of the machine’s hydraulic booms. The actuator’s housings rotate and are bolt-mounted to the drill-feed assembly which creates a simplified installation.

Helical actuators meet a wide variety of needs for heavy-duty equipment with respect to moving, supporting and rotating large loads. Learn more about designing your equipment with Parker Helac’s line of helical actuators.

This article was contributed by Daniel Morgado applications engineer, Helac Business Unit, Cylinder Division. Licensing for the images came with permission from the Parker Hannifin Media Manager collection.

We are official suppliers for Parker hydraulic equipment and components and trusted by customers in 130 countries worldwide! How can we help?

Discover more free educational content from Parker within our Fluid Power Technical Knowledge Hub…

Check Valves are the Unsung Heroes of Fluid Power

Check valves are unseen and undervalued. These valves are found in just about every mobile and industrial hydraulic system on the planet. Simply put, if there’s a pump, most likely you will find a check valve.

Surprisingly, for a valve that performs such a critical function, a check valve incorporates very few components – the body, poppet, spring and retainer.

Learn More

Three Reasons to choose the Parker V16 Variable Displacement Motor

Parker V16 Series is the next generation of variable displacement, bent-axis motors. It further develops Parker’s well-known V12 and V14 hydraulic motor series.

It is designed for both open and closed circuit transmissions focusing on high-performance machines and demanding mobile applications.

Learn MoreSix things you never knew about Heavy Duty Hydrostatic Piston Pumps and Motors

Parker Gold Cup heavy-duty pumps and motors have long been respected in the industry for technical excellence in hydrostatic transmission applications in marine, drilling, and shredding applications, among others.

But you may not be aware of Gold Cup’s, heavy-duty hydrostatic piston pump and motor value-added features and benefits…

Learn More