The FPA Triangle is based on the work of the French mathematician Blaise Pascal and Italian scientist Daniel Bernoulli. You can find out more about the lives of these two influential scientists in our Hydraulics Heroes e-book.

In a hydraulic system, the major function of the hydraulic fluid is to provide energy transmission. It’s also worth noting that, depending on your hydraulic circuit, your hydraulic fluid will also fulfil a number of other important roles, such as: lubrication, heat transfer, fire resistance and contamination control.

The science of fluid dynamics

Hydraulic systems are based on the principles of fluid dynamics; this important branch of science deals with the movement of fluids. An understanding of the key principles of fluid dynamics is, therefore, essential for anyone who wishes to build or maintain hydraulic systems. One of the first concepts that must be understood is how physicists quantify the movement of fluids, namely flow.

The two main factors which affect the flow of fluids are pressure and density, so these concepts are also fundamental to the study of hydraulics.

In this article, we will consider the key concepts of pressure and flow and how they apply to hydraulic systems – as it is the pressure and flow which enable work and motion to be accomplished.

What do we mean by flow?

The flow of a fluid describes the movement of that fluid as it, for example, passes through a pipe or runs along a surface. It has two components: flow rate and flow velocity.

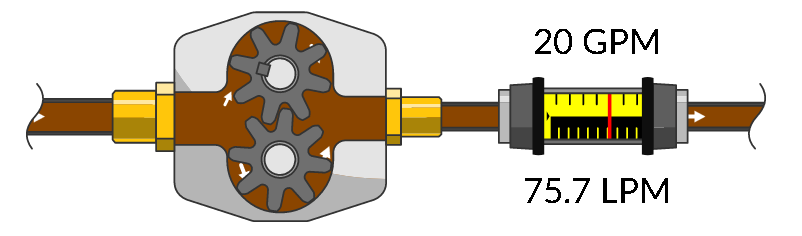

Flow rate is the movement of a specific volume of fluid in a set amount of time. Flow rate is typically measure in litres/minute (lpm), or U.S. gallons per minute (gpm), using a flow meter.

Flow characteristics: laminar flow or turbulent flow?

An understanding of the different ways in which liquid flows – and what causes these differences – is absolutely essential to hydraulic system design.

Flow can be characterised in a number of ways, for example: steady or unsteady flow; laminar or turbulent flow. For a fantastic, visual explanation of these different types of flow, it’s worth heading over to LunchBox Sessions’ website. Their online content is packed with interactive learning materials for paying members. Some of their learning materials are free; you don’t need to sign up – and that’s where the images in this article have been sourced from. LunchBox Sessions have kindly allowed us to reproduce some of their e-learning content here. We encourage you to take a closer look at their site: it’s a fantastic resource if you want to know more about how hydraulics and other industrial technologies work.

We will continue by providing a summary here.

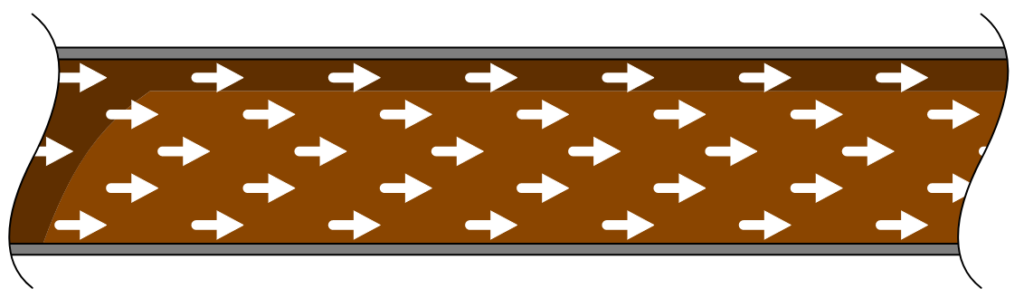

Laminar flow

People usually think that fluid flows as one single mass, but that is not the case in reality. At low speeds, fluid flows in distinct, parallel layers – each of these moves at a slightly different rate. This phenomenon is known as laminar flow.

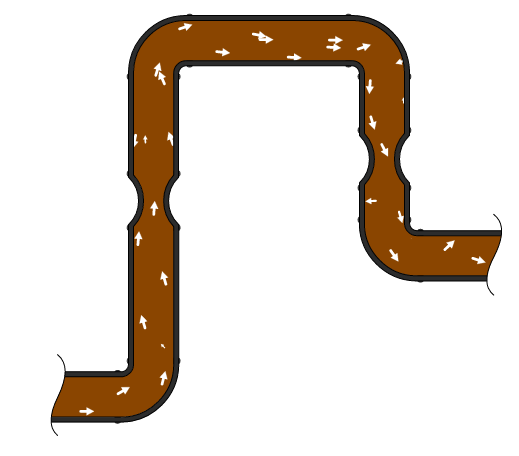

Turbulent flow

As the velocity of a fluid increases, tiny imperfections in the surface of the flow conductor, i.e. the hose, tube or pipe, disturb the flow path. This creates a chaotic state disrupting the otherwise organised layers of laminar flow.

In a hydraulic system, turbulent flow can be found anywhere where bends and restrictions occur. Larger hoses and fittings can therefore help to reduce this effect. The friction of this turbulent flow also leads to an increase in heat.

As we can see from these LunchBox Sessions’ illustrations, the way the fluid flows through our hydraulic system will affect our system design in many ways, namely the: choice of fluid; number of restrictions; size of hoses; size of fittings; heat dissipation and cooling systems.

We measure and explain this flow phenomenon using a statistic called the Reynolds number. This equation was developed by physicist George Gabriel Stokes and named after the nineteenth century scientist Osborne Reynolds. A low Reynolds number indicates a smooth, laminar flow and a high Reynolds number usually indicates a flow that is more turbulent.

What do we mean by pressure?

In a hydraulic system, pressure is usually created by restricting the flow of the fluid, or by gravity. Click through to LunchBox Sessions again to see this illustrated using two common everyday examples.

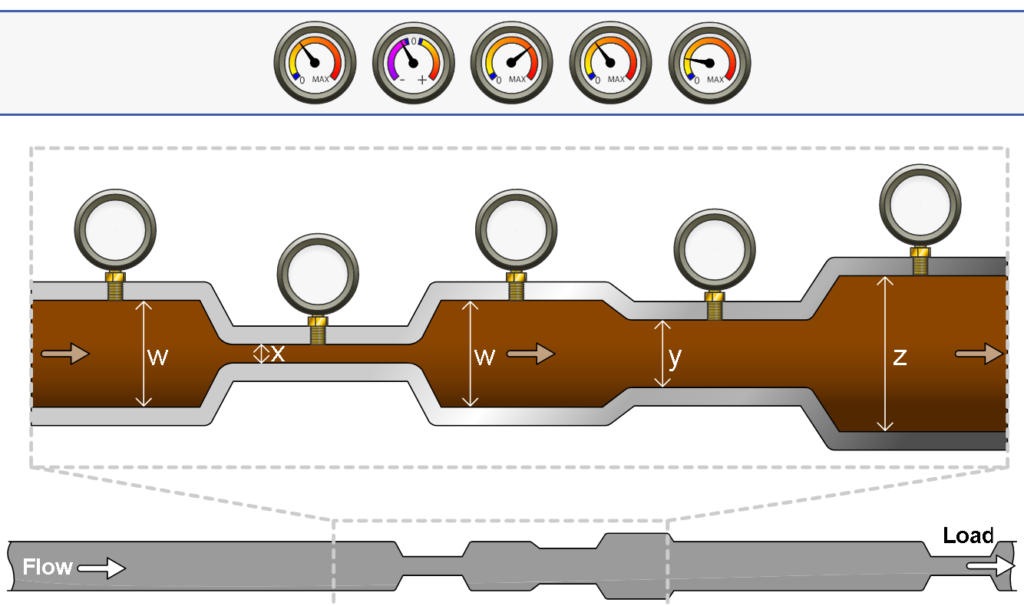

Bernoulli’s Puzzle

For an interactive explanation of how these phenomena are used within a hydraulic system, you can also check out this puzzle on LunchBox Sessions’ website to test your own understanding.

As fluid flows through this oddly shaped section of pipe, Bernoulli’s Principle predicts that the pressure will fluctuate as the pipe’s diameter changes. If you click on the image here you can visit LunchBox Sessions website to drag and drop the gauges to indicate the relative pressure of each section.

Once we understand this, we can begin to see how pressure is used in a hydraulic system to create the force that drives the motion or work the system is designed to do.

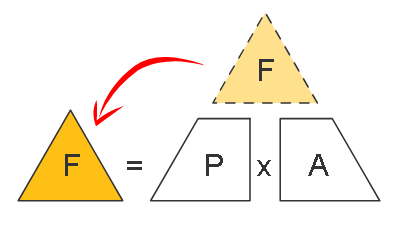

The FPA Triangle

There is a direct mathematical relationship between the:

- force that a hydraulic system is capable of transferring;

- pressure of the system and;

- surface area of the component being driven.

This relationship is often expressed using the FPA Triangle. Take a look at this explanation from LunchBox Sessions.

You can continue this session by downloading another of our ebooks: the Beginner’s Guide to Hydraulics. This provides a detailed explanation of the relationship between pressure and force and how they are used within a hydraulic system.

If you’re looking for hydraulic system design expertise, please get in touch with our helpful team for guidance and quotations. Contact us here.

If you enjoyed this introduction to hydraulic pressure and flow you should explore our other collaborations with Lunchbox Sessions…

Specifying Hydraulic Hoses

Hydraulic hoses convey the hydraulic fluid around the hydraulic system; they are not minor accessories.

No matter how big or small, a hose burst failure on a hydraulic system is always a catastrophic incident. Careful consideration must always be given to their specification and installation.

Learn moreUsing Pressure Readings to Diagnose Problems

Effective troubleshooting of problems in hydraulic systems requires a good understanding of flow and pressure readings.

In this article, we’re going to look at how pressure and flow can vary depending on the type of hydraulic system and what implications this has for hydraulic system troubleshooting.

Learn MoreTroubleshooting Hydraulic Systems: the Reservoir, Breather and Fluid Contaminants

The hydraulic reservoir plays an important part in hydraulic circuit design – storing hydraulic fluid when it isn’t being pushed through the hydraulic system.

While a “fluid storage tank” might seem like a very simple concept, the design and implementation of the reservoir is very important.

Learn more