From efficiency, controllability and versatility to noise and vibration control, learn how smarter hydraulic pump drive systems can benefit industrial applications.

To remain a competitive player in today’s hydraulic market, users must begin to upgrade to the technology that allows systems to work smarter, not just harder. The ability to dynamically control machines is game-changing. Technology is making it possible to design and build machine components that do more than simply react to the commands we give them.

More and more end users in industrial applications are looking for machines with smarter components. Expectations are being elevated and it’s becoming clear that today’s smart is tomorrow’s not-so-smart. Pump suppliers and end users are expecting original equipment manufacturers (OEMs) to recognise these technology differences and incorporate smarter technology in the machines of today and tomorrow to help perform their functions in a more efficient way.

OEMs should consider at least four main issues when considering a switch to a “smarter” hydraulic pump drive system for their equipment:

1. Efficiency

Just getting the job done isn’t enough anymore. Smarter machines provide the capability to improve efficiency – getting more work done faster at a lower cost. If efficiency is an issue with your application, you might want to consider upgrading your hydraulic pump to a smarter one.

2 – Controllability

Smart hydraulic pumps allow for a high degree of control over the entire hydraulic system. Strategic placement of sensors within the system allows the pump to provide the exact flow and pressure needed in accordance with the specific demands of each stage of the production cycle. This allows for enhancements in product quality, energy usage and overall machine efficiency.

3 – Versatility

Sometimes, your application needs operational flexibility. Smart pumps are capable of running in different modes depending on your specs and requirements. Maybe your manufacturing process requires full power, all the time. Or, maybe it doesn’t need a pump to run full bore and could save energy usage by using a pump that knows when to hold back on power.

4 – Noise and Vibration Control

In order to meet the latest noise pollution regulations and protect your employees, you need a pump drive system that minimizes noise and vibration. An additional benefit of this reduction can be more precise finished products because of increased equipment stability. Maintenance costs can also decrease due to less wear and tear on parts not susceptible to unnecessary movement.

Smarter hydraulic pump drive systems

Smarter hydraulic pump drive systems – like the Eaton X20 series of mobile open circuit pumps – balance power generation and control with power consumption.

They help automate the many micro-decisions in the hydraulic system work circuit so that when the operator pushes a button or pulls a lever, the machine adapts and responds smoothly and efficiently.

Reproduced with kind permission from Eaton Hydraulics. Authorised and regulated by Eaton. All rights reserved.

Hydraulics Online is the first choice for customers worldwide – supplying a huge range of hydraulic brands and components and guaranteeing you impartial, technical advice and optimal solutions. How can we help?

Expand your Knowledge with more Free Content from our Technical Knowledge Hub…

Selecting Hydraulic Fluid for your Hydraulic Pump

The hydraulic fluid is one of the most important components in the system yet it is often overlooked…

The fluid is the medium for the transmission of power and without sufficient fluid, no work can take place. It also performs functions such as lubrication, heat transfer and allows the conveyance of debris and contamination.

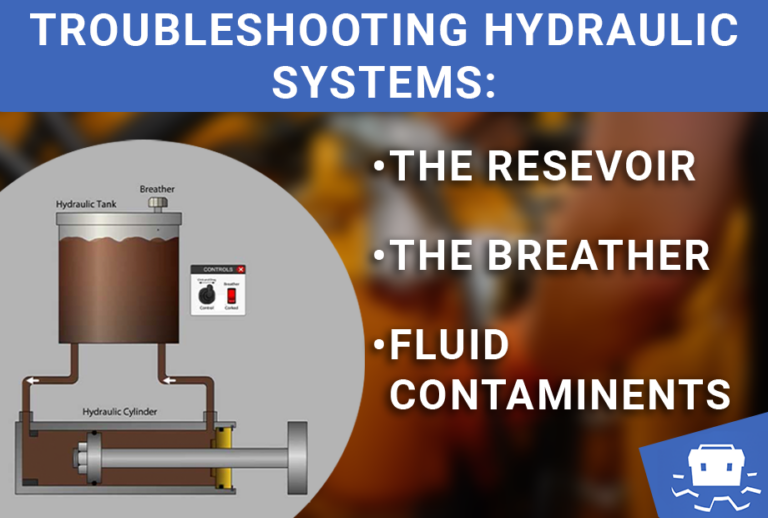

Troubleshooting Hydraulic Systems:

While a “fluid storage tank” might seem like a very simple concept, the design and implementation of the reservoir is very important.

The efficiency of even the most well-designed hydraulic system can be undermined by poor hydraulic reservoir design.

Learn More

An Introduction to Hydraulic Pressure and Flow

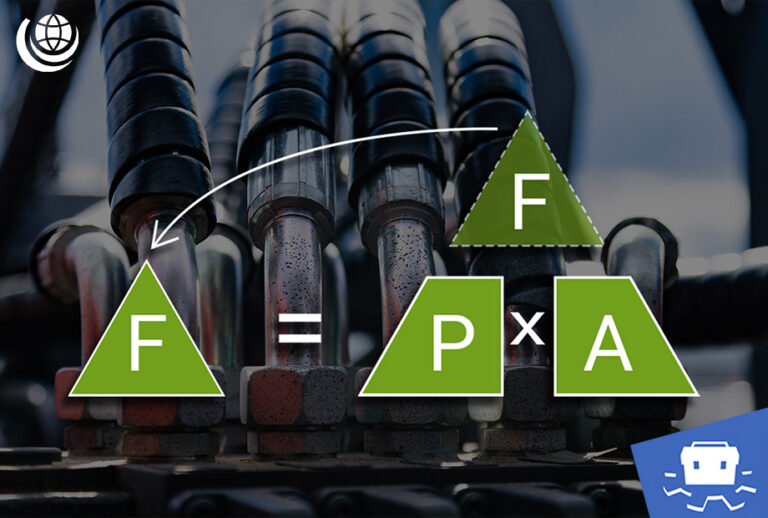

Hydraulic systems are based on the principles of fluid dynamics; this important branch of science deals with the movement of fluids.

An understanding of the key principles of fluid dynamics is, therefore, essential for anyone who wishes to build or maintain hydraulic systems.

Learn More