Hydraulic filtration technology plays a fundamental role in the range of components and systems offered by ARGO-HYTOS. Quite simply, the company’s numerous innovative solutions in the fields of industrial and mobile hydraulics would not be possible without filtration. But how exactly does filtration technology work, and what role does it play in plant and machinery?

In this article, reproduced with kind permission from ARGO-HYTOS, we answer these questions and more.

How does a hydraulic filter work?

Filters act like a screen. They retain solids from fluid or gas streams. In the case of screens, a solids-free filtrate and a filter cake are produced from the captured solids.

However, the separation does not occur autonomously, but only as a result of the pressure difference in the transport medium upstream and downstream of the filter medium. For this pressure difference, the medium can be forced through the filter with positive pressure or sucked through it with negative pressure. Likewise, hydrostatic pressure or centrifugal force provides the drive of a filtration.

Hydraulic filtration principles

In hydraulics, surface filtration and depth filtration are the most common.

Surface filtration filters have geometrically defined gaps; the particles are separated on the surface. In the case of very high dirt accumulation, a filter cake grows on the filter (screen mesh), which acts like an additional filter as its thickness increases. This filter cake should be removed regularly to maintain control over the filtration process.

Depth filtration filters use nonwovens with chaotically arranged fibres, between which the solid particles are separated in depth. Cleaning of the filter material (e.g. glass fibre fleece) is not possible. Therefore, the filters must be replaced when they are completely contaminated. Depth filtration is mainly used where only the fluid is to be reused. Dirty filter inserts are disposed of.

The science behind filtration

For filtration, filter media are selected whose gaps, or pores, are smaller than the size of the particles to be separated. In addition, the inertia of the dirt particles in fluid flows ensures separation on the filter material. In the case of gases, electrostatics also support filtration. For this purpose, the nonwoven filters used there receive an electrical charge in all their fibres.

Various filter media

Nonwovens made of cellulose, glass fibre, or plastic are not only used for the filtration of gases. They are used just as much for the filtration of fluids as for:

- fabrics made of plastic or metal wires,

- porous solids (mostly sintered metals) and

- bulk materials.

In the future, nanofilters will provide even more refined filtration.

Often, modern filter materials are still chemically, or physically, treated to increase or optimize their natural filter properties.

Which filter media does ARGO-HYTOS use?

In their suction filters for tank installation, for example, you will find screen mesh made of closely woven polyester wires. This has a mesh size of 135 micrometers or 0.135 millimeters, for example.

Other filters, such as the ARGO-HYTOS return flow filters for in-line installation, achieve even more. With multilayer glass fibre fleeces, they even retain particles smaller than ten micrometers or 0.01 millimeters in size.

These two examples from the ARGO-HYTOS portfolio of hydraulic filtration technology show you the precision that is possible today – a portfolio that is constantly being developed further.

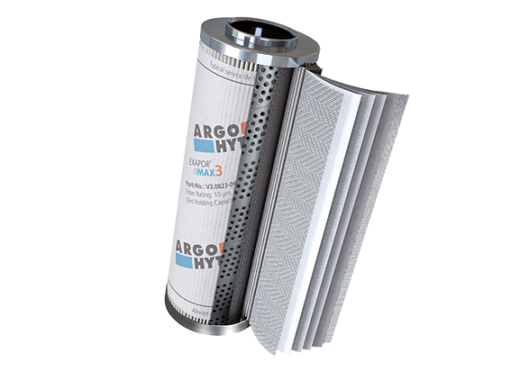

This is done, for example, with the EXAPOR®MAX 3 filter elements, the successors to the successful EXAPOR®MAX 2 model. The third generation of this filter design reduces pressure loss by up to 20 percent once again. It also has up to 15 percent greater dirt-holding capacity and many other advantages.

You can realise these benefits day-after-day in your plant and machinery: with higher machine availability, longer maintenance intervals and lower operating costs.

Important features of a filter

The quality or efficiency of a filter can be recognised by various specifications or features. These are discussed briefly below.

Filtration ratio and separation efficiency:

The filtration quotient ß is calculated, similarly to an efficiency, as the ratio of the particle count before the filter and the particle count after the filter. The filtration efficiency processes the filtration quotient to show as a percentage how efficiently a filter separates dirt particles from a fluid.

Dirt-holding:

There are two specifications for this feature: absolute dirt holding capacity in grams, and specific dirt holding capacity in milligrams per square centimeter. Both are only used in connection with depth filters.

Pressure drop:

When fluids flow through a filter, there is regularly a pressure drop. There is an initial pressure drop for any filter that is not yet in use. The more dirt is retained, the greater the pressure rise at the filter. This effect is also used by clogging indicators to indicate the optimum time for filter maintenance.

Cleaning:

Robustly constructed surface filters by ARGO-HYTOS can be cleaned up to 3 times. Depth filters, used for medium dirt accumulation and flowed through with nominal volume flow, can be used for at least 1000 operating hours. In principle, replacement is recommended once a year. By the way: 1000 operating hours correspond to a mileage of 60,000 km for a passenger car.

Which hydraulic filtration technology does ARGO-HYTOS offer?

ARGO-HYTOS gear pumps for industrial and mobile hydraulics operate with various oils and lubricants. Even in optimum quality, new oils contain too many contaminants and should not be used without being filtered. The size of these dirt particles is usually only in the range of a few micrometers, which makes them invisible to the human eye. Nevertheless, this is enough to cause long-term damage to plant or machinery.

The first thing that then happens is more frequent plant breakdowns with the need for repairs and expensive downtime. Overall, the service life of the machines decreases, causing further high costs. In contrast, the investment in a suitable filter system is marginal. ARGO HYTOS integrate suitable filters directly into their systems or machines. However, they also offer individual filters for installation or retrofitting in your systems.

»

»

Suction filters:

Suction filters are installed in tanks, on a suction connection or directly on the suction line of pumps. Suction filters protect precisely these pumps from contaminants that are sucked in from the tank. When planning a system, you must always take into account how the filters affect pump performance.

Suction filters are also not very suitable for fine filtration. In this case, they create too much negative pressure in the suction line.

»

»

Return filters:

ARGO-HYTOS return filters are available as tank top filters, in-tank filters and in-line filters. In order to clean the returning oil before it enters the tank, the use of a return filter is recommended. It is installed directly on the tank or at the end of the return line.

»

»

Pressure filters:

You integrate pressure filters directly after a pump in the pressure line. The filters then protect all downstream components. In addition to pressure filters up to approximately 100 bar operating pressure, ARGO-HYTOS also offer high-pressure filters.

»

»

Filling and ventilating filters:

You place these filters directly on your hydraulic tank. There, they provide filtration of the incoming air and thus prevent the entry of dirt from the atmosphere. The filter fineness of the ventilating filter should be finer than that of the finest filter in the hydraulic circuit.

»

»

Filter units:

Off-line units filter the pressure fluid in a separate circuit. In this way, you relieve the filters in the main stream. This allows you to operate the entire system more efficiently.

ARGO-HYTOS Products

Click below to discover more from ARGO-HYTOS including their hydraulic filtration products, pumps, manifolds, pressure switches, valves, solenoid systems and accessories.

ARGO-HYTOSWhat are the selection criteria for filter technology?

When selecting hydraulic filtration, it is crucial to pay attention to:

- Filter fineness – derived from the required oil cleanliness,

- Differential pressure or filtration stability,

- Size/duration and other installation criteria,

- Media compatibility as well as viscosity,

- Design conditions and

- Hydraulic conditions.

Finally, check the operating conditions regularly and change the filter element according to the manufacturer’s specifications, or at least once a year. The cost of this will quickly pay for itself compared to that of defective equipment.

We’re a hydraulics ‘hub’, offering thousands of possibilities… how can we help?

More articles from Argo Hytos…

How to use overcentre valves correctly

In the world of hydraulics, overcentre valves provide precise control and regulation of loads. They provide three essential functions in one component: check valve, pressure relief and cavitation protection. This combination enables efficient, safe and powerful handling of hydraulic systems.

Learn MoreAll you need to know about a pressure reducing valve

A pressure reducing valve is used in line or hose systems. Also known as pressure regulating valves, these components regulate high or fluctuating inlet pressures in the system to a predefined outlet pressure. In this way, the valves keep the pressure constant.

Learn moreProportional valves: designs and operation methods

Numerous applications and systems require a highly precise adjustment of the pressure and/or the volume flow according to the needs of the particular operating system. This task is performed by proportional valves.

Learn more