Numerous applications and systems require a highly precise adjustment of the pressure and/or the volume flow according to the needs of the particular operating system. This task is performed by proportional valves.

In this article, reproduced with kind permission from ARGO-HYTOS, we look at how proportional valves are used, what types are available and how are they connected and controlled.

What are proportional valves?

Unlike switching valves, proportional valves not only assume an open or closed state, but can also adopt any intermediate positions. The continuous change of state places high demands on the valve design.

In the case of electromagnetic proportional directional valves, electromagnetic actuation systems act on the valve piston and change the opening transverse steps against the return spring and hydraulic forces in proportion to the applied current.

Electromagnetic proportional pressure valves, on the other hand, establish a balance of forces between the actuation system and the hydraulic forces on the effective surfaces via a plug or piston with defined effective surfaces. In this way, pressures can be set, regulated or reduced.

There are three basic types of such proportional valves:

- pressure relief and reducing valves

- directional valves

- flow control valves

These three types are then each divided into further variants of proportional valves. Many of these can be found within the range of ARGO-HYTOS proportional valves.

Here, in addition to directly controlled proportional directional valves such as the PRM2-04, you can also get pilot operated proportional directional valves such as the PRM8-06.

Direct-operated and pilot-operated pressure relief valves such as SR1P2-A2 and pressure reducing valves, for example SP4P2-B3, are available for the common ¾ and ⅞ UNF form bores. Proportional flow control valves such as the SF32P-C3/H, among others, are offered as screw-in valves.

How are ARGO-HYTOS proportional valves connected?

All ARGO-HYTOS valves, including proportional valves, are developed in different designs:

- as flange-mounted valves in ISO 4401

- as installation valves for UNF – shaped bores

- as sandwich plate valves in ISO4401

- supplementary subplates, manifold plates and pipeline housings

Regulation or control concepts of ARGO-HYTOS proportional valves

If the controller of the valve receives an input signal, it activates the corresponding solenoid. This then regulates the valve continuously. The regulation or control can be done in three ways:

- without feedback

- with an internal feedback via a slide position sensor

- including external feedback with a closed-loop sensor

Proportional Directional Valves

This variant according to ISO 4401 is available as 4/2 or as 4/3 proportional directional control valve. These valves are available in sizes from DN 04 to DN 10. Each size can regulate two or three volume flow sizes. A pressure compensator can also be used to achieve load-independent volume flow control.

As with many other valves, direct control is typical here. It takes place via poppet or spool elements. We also have pilot-operated valves in our range. In these, the actuator only operates the control stage. The main stage is actuated hydraulically. This principle allows significantly higher hydraulic outputs to be controlled and regulated.

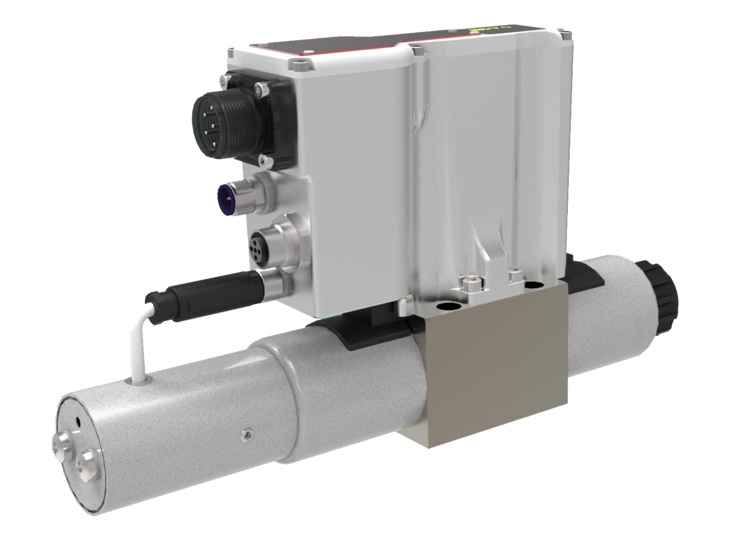

This is impressively demonstrated by the PRM8-06 pilot-operated proportional directional control valve, which is designed for maximum performance. It can handle pressures of up to 350 bar and flow rates of up to 130 liters per minute with a DN-06 size. If you need advanced digital control capabilities in addition to high performance, the PRM9-06 proportional directional control valve, for example, is a good choice.

This valve comes to you with digital onboard electronics including CAN bus communication interface. This makes it ready for the requirements of Industry 4.0.

Proportional pressure relief valves

With pressure relief valves you make a fine adjustment of the maximum pressure in the system. You can also control the valve remotely via a solenoid. For this purpose, our pressure relief valves use the EL6 digital control electronics with DIN plug.

Here too, ARGO-HYTOS, have developed valves with different performance characteristics. They control a flow rate of up to 60 litres per minute – up to a pressure of 350 bar.

Proportional pressure relief valves are offered in versions with rising or falling characteristic. Valves with rising characteristic are characterized by the fact that as the current in the actuating solenoid increases, the system pressure increases proportionally.

In contrast, proportionally operating pressure relief valves with inverse or falling characteristic cause the lowest system pressure through maximum current flow in the actuating solenoid. This is required, for example, for hydraulic fan drives in mobile machinery, as the fan is accelerated to maximum speed in the event of a malfunction.

However, many applications also work with low pressure – above all transmission or clutch controls in mobile equipment. For this purpose, you need adapted proportional pressure reducing valves such as the ARGO-HYTOS PP2P3-W3, which are available from us either directly or pilot operated. The valves are designed for an inlet pressure of up to 50 bar and operate with a maximum control pressure of between 20 and 30 bar.

Solenoids

ARGO-HYTOS cater for single components through to complete system solutions for industrial or mobile hydraulics. For the control of proportional valves or other valves, you often need an electromagnetic actuation system: ARGO-HYTOS actuation systems work as a perfect team with ARGO-HYTOS proportional valves.

With this in mind, ARGO-HYTOS actuation systems boast a number of ideal features thanks to their high-precision manufacturing.

Low hysteresis requires minimal friction and precise guidance of the armature. Here, attention to detail and high-quality manufacturing with precision in the micrometer range are crucial. ARGO-HYTOS design with soldered pole tubes, high-quality materials, modern manufacturing processes and comprehensive quality controls to deliver the required precision and reliability in all their components.

ARGO-HYTOS always think about the simplest possible application or maintenance within your systems and processes. As an example, their solenoid coils are also designed for uncomplicated use. The coils of the actuation systems can be rotated around the longitudinal axis, which allows optimal connector positioning. If a coil needs to be replaced, this can be done easily without having to open the hydraulic circuit.

Please contact our award-winning team for technical advice and configuration options on ARGO-HYTOS proportional valves – we’ll be delighted to help!

Find more Content from Argo Hytos within our Fluid Power Technical Knowledge Hub…

How to use Overcentre Valves Correctly

In the world of hydraulic enginerring, overcentre valves provide precise control and regulation of loads. They provide three essential functions in one component: check valve, pressure relief and cavitation protection. This combination enables efficient, safe and powerful handling of hydraulic systems.

Learn More

Hydraulic Manifolds: Features and Applications

Take a look in detail at the technical properties of manifolds and the various industrial and mobile hydraulic applications that use them.

Read on to learn how these high-precision components significantly influence the operation and performance of machines and systems.

Learn MoreAll you need to know about Pressure Reducing Valves

A pressure reducing valve is used in line or hose systems.

Also known as pressure regulating valves, these components regulate high or fluctuating inlet pressures in the system to a predefined outlet pressure. In this way, the valves keep the pressure constant.

Learn More