Flow control valves are the invisible heroes in a hydraulic system. They play a crucial role in controlling the volume flow of the hydraulic oil within the circuit and have a direct influence on the speed of the oil flow and the connected actuator. An efficiently operating flow control valve ensures that the flow remains constant despite changing loads.

There are a large number of varying designs that can be used, depending on the application and required functionality, that differ in their design, operating and adjustment principles.

In this article, reproduced with kind permission from ARGO-HYTOS, we take a closer look at the different types of flow control valves that are available. In addition, we provide hints and tips on how to correctly use the highly specialized valves from the ARGO-HYTOS range.

What are flow control valves used for?

ARGO-HYTOS flow control valves perform an essential function in hydraulic systems. They control the volume flow of the hydraulic oil and thus the speed of the connected actuator. This can be a hydraulic motor, a cylinder or another hydraulic consumer. In this way, the valves enable precise control of the speed of hydraulic movements.

Of particular note is the ability to maintain constant flow in the system, even when load conditions change. This ensures continuous and reliable system performance. In special cases, such as proportional flow control valves, the adjustment of flow is electromagnetic. This provides extremely sensitive and smooth control.

Other variants, such as 3-way flow control valves, selectively discharge surplus flow, minimising energy losses and increasing system efficiency. Flow dividers and unifiers enable volume flows to be split or merged in complex hydraulic systems.

Possible applications and examples of flow control valves

The diversity of flow control valves means that they can be used in a wide range of applications and fields of use in hydraulic systems engineering. They play a decisive role in controlling the volume flow of the hydraulic oil. In addition, they have a direct influence on the speed of the oil flow and the connected actuator. In this next section we will look at some specific examples.

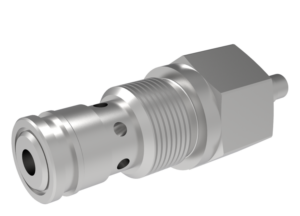

Restrictor valves

Restrictor valves limit the flow of the hydraulic oil by narrowing the cross-section and generate a back pressure on the supply side. Depending on the pressure difference upstream and downstream of the component, a corresponding volume flow is established.

Restrictor valves are particularly suitable for use in uncompensated systems and can be used as shut-off valves by closing completely. They are often used in hydraulic cylinders that operate under relatively constant load conditions.

One example of restrictor valves from the ARGO-HYTOS portfolio is the ST21A-B2 needle restrictor valve. This hydraulic needle restrictor valve is designed as a screw-in cartridge and allows throttling of the volume flow in both directions. The valve is primarily used in uncompensated systems or as a shut-off valve.

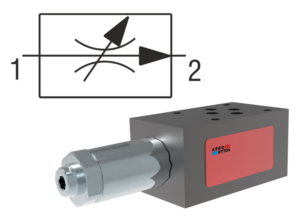

2-way flow control valves

2-way flow control valves allow controlled flow in one direction only. They can be used, for example, in hydraulic motors to regulate the speed or in hydraulic cylinders to control the speed of movement. By controlling the flow direction in this specific way, they allow effective control of the system.

With the SF2C2A-K2/I, ARGO-HYTOS offers a pressure compensated 2-way flow control valve with check valve. It is often used for the control of volume flows – independent of pressure and temperature. This valve is best suited for applications where speed changes due to load changes are not necessary.

3-way flow control valves

Unlike 2-way flow control valves, 3-way flow control valves have three ports. They direct surplus flow to the tank or other consumers, causing less energy loss than 2-way valves. With this type of valve, the control flow has priority, which allows accurate control of the system.

The VSS1-306 3-way flow control valve, for example, is optimized to deliver a controlled volume flow to the consumer even when system pressure fluctuates. The valve prioritizes the volume flow, while surplus pressurized oil is returned to the tank.

Flow divider and unifier

Flow dividers and unifiers are special valves that evenly divide the flow between two outlets. They are used in hydraulic systems where the flow is to be divided between two consumers (inlet control). However, they can also be used as flow unifiers to concentrate the flow (outlet control).

The SFD2F-B4/I is a flow divider and unifier from ARGO-HYTOS that splits a pump flow to two actuators even with different loads. This valve is used in synchronous controls and differential locks and offers highest accuracy even with load and pressure differences.

Proportional flow control valves

Proportional flow control valves represent a high-tech option. With them, the adjustment of the controlled oil flow is electromagnetic, made possible by process variables and a controller. They allow stepless control of flow by converting an electric current into an internal hydraulic manipulated variable. As a result, they provide precise and flexible control of the hydraulic system.

Construction principles and designs

The versatility and flexibility of flow control valves are evident in their application possibilities and functions together with their different design principles and construction forms. When selecting the right valve for your hydraulic system, the specific functionality requirements must be taken into account. The requirements for installation and control options are also important.

Construction principles

There are four main construction principles used in the design of flow control valves: mechanically directly controlled, mechanically pilot operated, proportional direct electrical control and electrically proportionally pilot-operated.

- Mechanical direct operated valves respond directly to mechanical influences, for example by manual actuation or by the hydraulic pressure itself. They offer a robust and reliable solution but are limited in volume flow range and precision.

- Mechanically pilot operated valves use a smaller control stage to actuate a larger operating stage. This allows more precise control of the flow rate and a faster control flow range than direct operated valves.

- Electrically proportional direct operated valves allow precise and stepless control of the volume flow. They respond directly to an electrical signal and convert it into a corresponding hydraulic action.

- Electrically proportional pilot operated valves combine the precision of electrical actuation with the force transmission of hydraulic pilot control. This enables high control accuracy even with large volume flows.

Designs

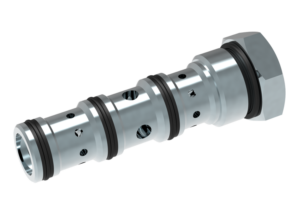

In terms of design, a distinction is mainly made between two types of flow control valves. These are screw-in valves for block installation and plug-in valves (also called slip-in valves) for block installation.

- Screw-in valves for block installation are compact and are particularly suitable for systems with limited space.

- Slip-in valves for block installation are plugged directly into corresponding holes in the hydraulic block. They allow easy assembly and disassembly and also offer high power density.

Intermediate plates for vertical stacking, in accordance with ISO 4401, allow valves to be installed in a valve stack configuration. This provides high flexibility in hydraulic system design and allows parallel control of multiple hydraulic functions.

The different design principles and styles of flow control valves offer a wide range of options for precise control of flow in the hydraulic system. By choosing the right valve for your individual application, you can optimize the efficiency and performance of your system.

Flow control valves are essential building blocks in hydraulics, enabling sensitive and precise control of oil flows. With a diverse range of valves, ARGO-HYTOS offer customized solutions for your applications and systems. Whether mechanically direct-controlled, pilot-controlled or electrically proportionally controlled, flow control valves contribute significantly to the efficiency and reliability of hydraulic systems.

Please contact our award-winning team for technical advice and configuration options on ARGO-HYTOS flow control valves – we’ll be delighted to help!