Description

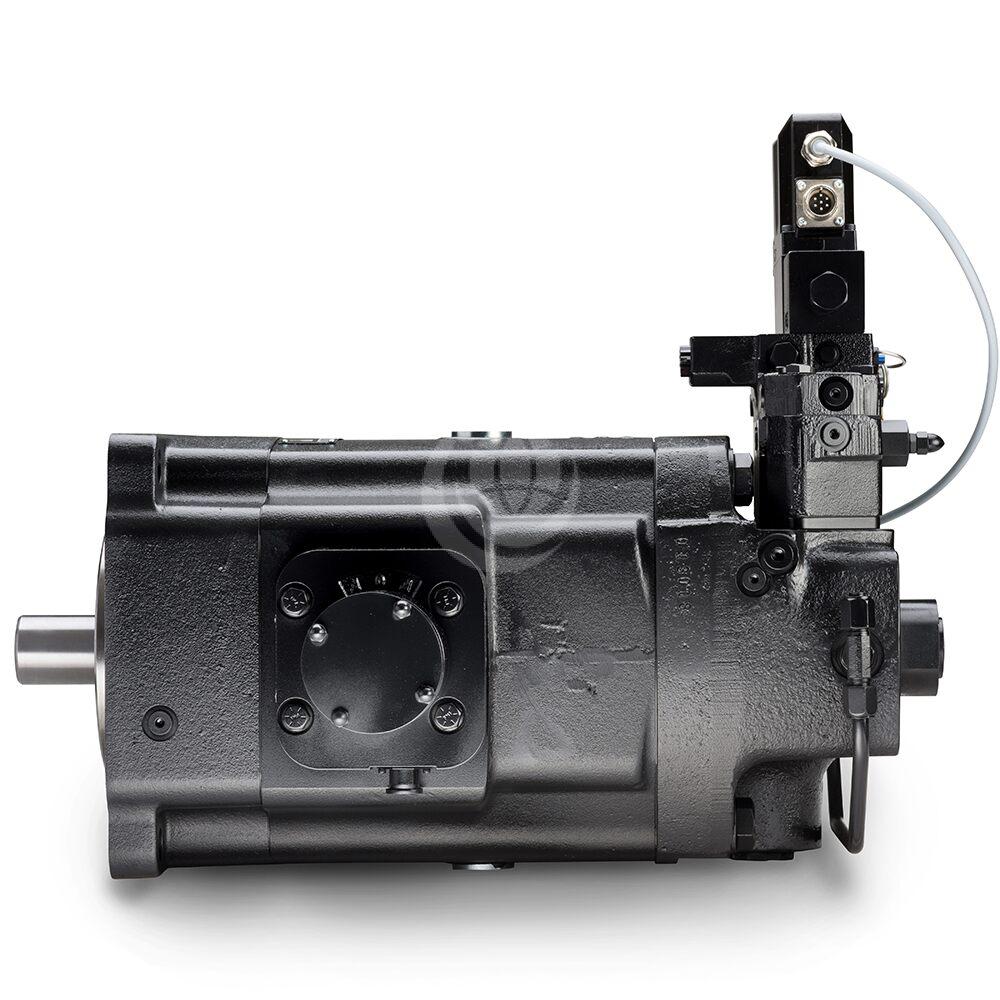

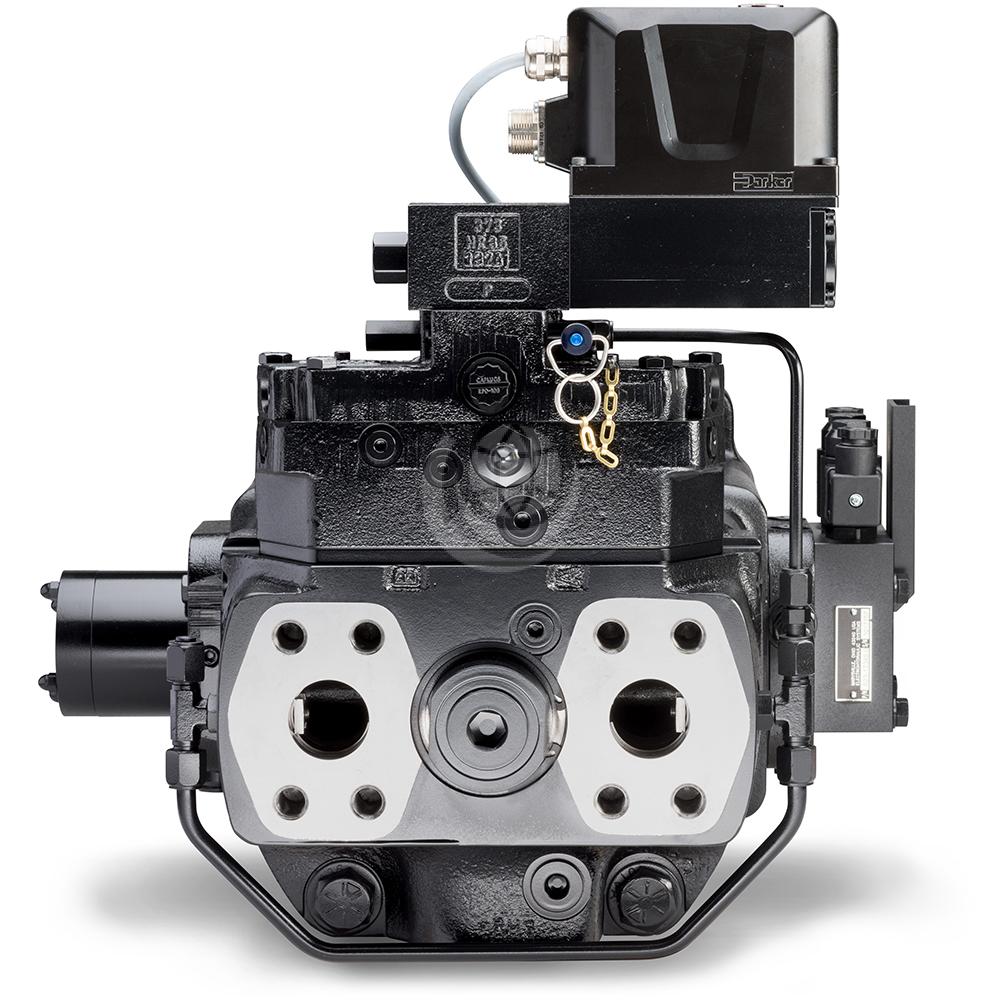

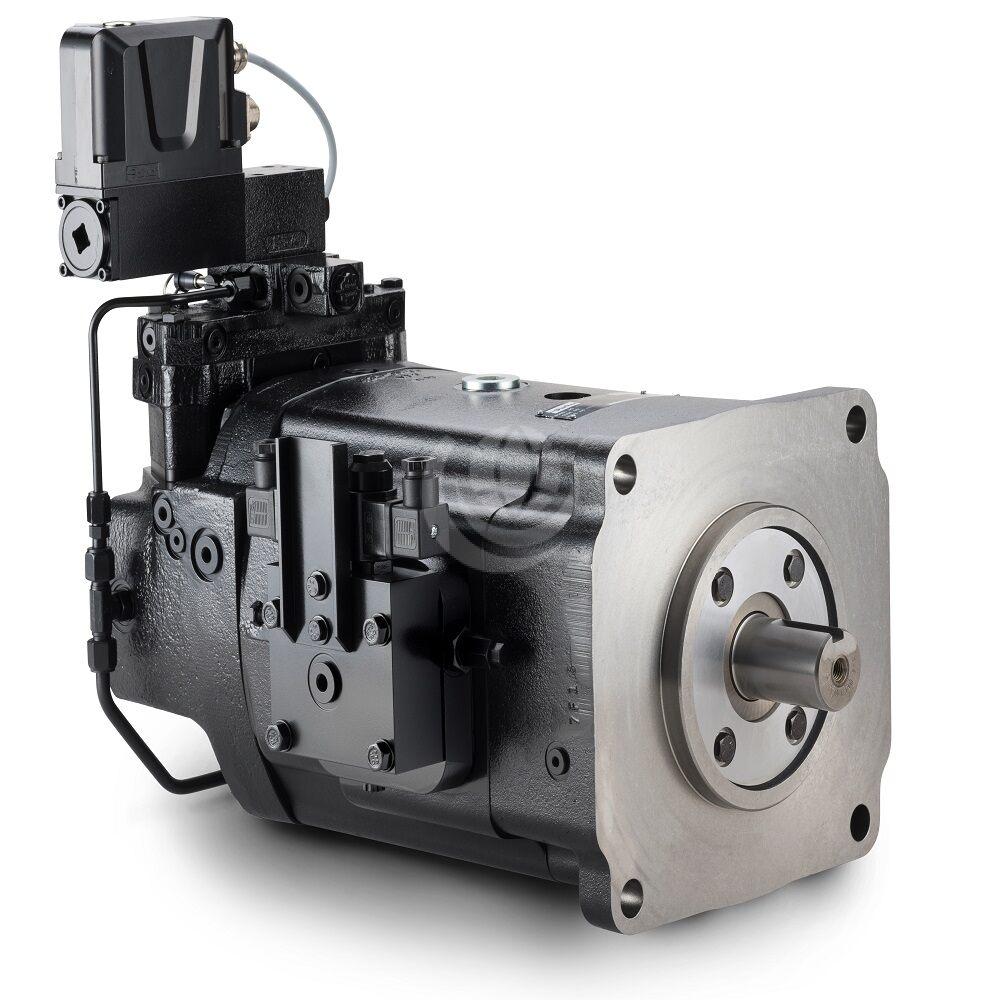

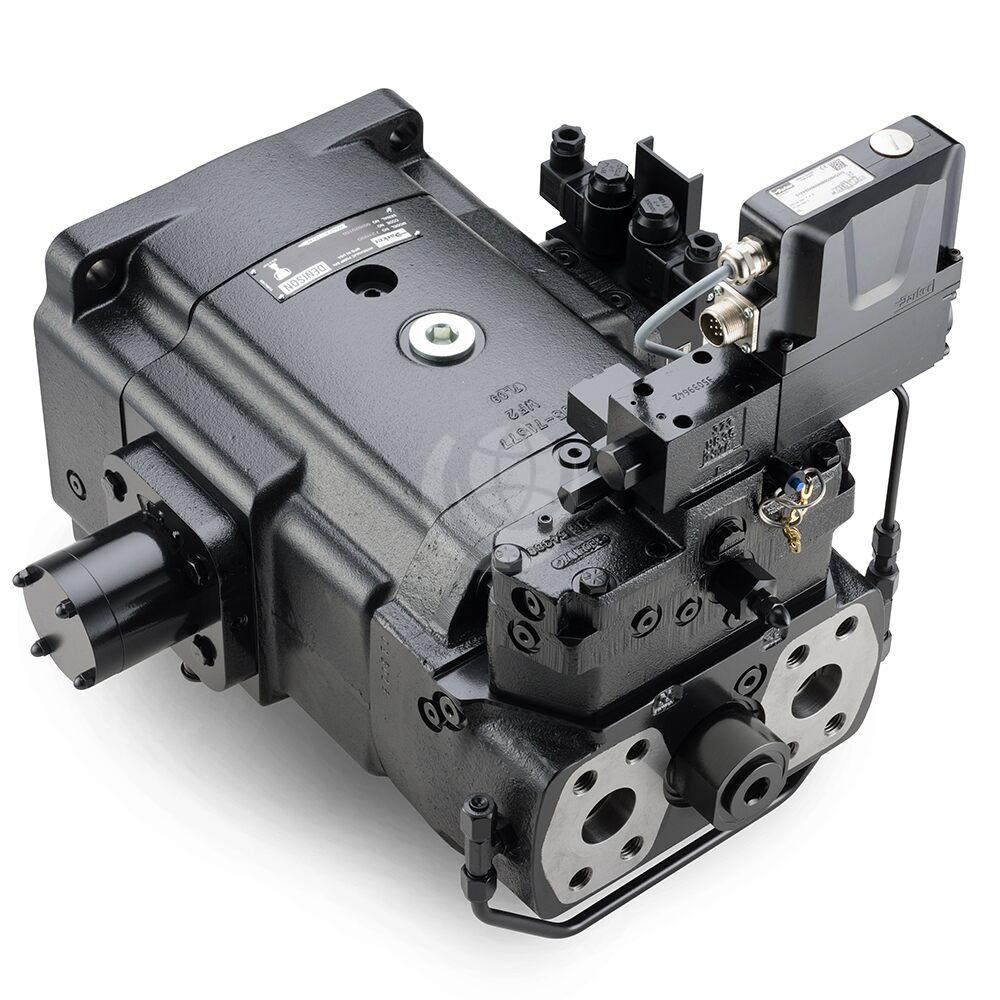

Parker Denison GOLD CUP axial piston pumps / motors are variable displacement and of an unparalleled rugged design. Capable of withstanding the harshest of conditions, the Denison GOLD CUP series has been designed to operate in a wide range of industries needing closed-loop control, high pressure, high power density including: blast hole drill rigs, cranes, marine, military, mining, power generation, pulp and paper and shredding.

Rated to 500 psi (350 bar) continuous pressure and continuous duty, the Denison GOLD CUP design has the unique feature of an internal servo/replenish and the ability to utilize system over pressure to directly control the stroking chambers. Controls are completely modular in design and can be configured to meet most any system requirements with standard factory options. All internal wear surfaces are hydrostatically balanced and/or hydraulically linked allowing for a long and serviceable life. The GOLD CUP pump also has the ability to run in many open circuit applications and also has digital (flow/pressure) capability for the most difficult of control requirements.

Summary technical data for the P8 GOLD CUP pump is as follows:

- Maximum displacement: 8.00 in³/rev / 131.1 cm³/rev

- Continuous pressure: 5000 psi / 350 bar

- Intermittent pressure: 5000 psi / 350 bar

- Maximum speed: 2700 rpm at full stroke

Parker Denison GOLD CUP pumps / motors also features such as:

- Modular controls and quick change valve block – easy to service or replace

- Versatile controls – located on either side of the pump for maximum freedom of design

- Dampened low inertia rocker cam – more stable, quieter and faster than other designs

- Exclusive zero-backlash rotary servo design, offering lifetime accuracy

- Field adjustable compensator override, easily adjusted without removing from machinery

- Precision barrel bearing – permits high speeds, high pressure and long life

- Ring-style replenishing – checks fastest operation with no sliding poppets or parts and low pressure drop

- Hot oil shuttle available – fast, reliable operation

- Auxiliary pump – can be changed without disassembling the transmission

- Standard SAE keyed or splined drive shafts

- High pressure mechanical shaft seals can be changed without disassembling the transmission (excluding the P24 and P30 models) with double lip seals also available

- One piece stroking vane/cam – no lost motion, zero backlash, better control, and no linkages to wear out

- Stroking vane seals are pressure loaded for longer life

- Standard compensator vent ports for a wide variety of controls

- Rocker cam displacement indicator helps troubleshoot the system

- Modulated servo pressure saves power

- Standard Code 62 SAE split flange connections;

- Fastest compensator response: gives maximum of 10% pressure overshoot at rated conditions (guaranteed times under all conditions, faster response times possible depending upon application)

- Certification approvals: ATEX, ABS, MIL-P-17869A and MIL-S-901-C Grade A

Download the P8 Gold Cup Technical Catalogue>>>

Contact us for further technical details and configuration options.