Parker Gold Cup heavy-duty pumps and motors have long been respected in the industry for technical excellence in hydrostatic transmission applications in marine, drilling, and shredding applications, among others.

You probably know that the heavy-duty Gold Cup series of pumps and motors represent Parker’s and Denison’s combined expertise in hydrostatic transmission applications.

The tried and true design incorporates features such as, integral servo and replenishing pump, hot oil shuttle, and a unique servo control system; all of which combine to provide a rugged self-contained package that can withstand the harshest of conditions and continue to perform with trouble-free long life.

But you may not be aware of Gold Cup’s, heavy-duty hydrostatic piston pump and motor value-added features and benefits listed below:

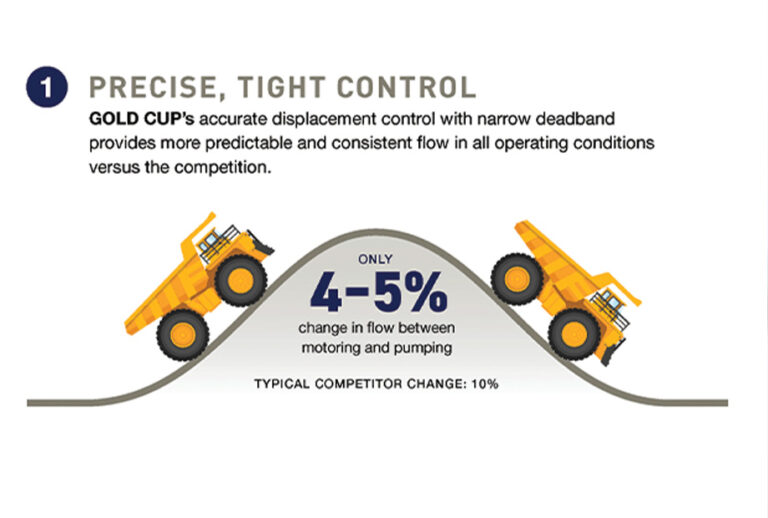

- Precise, tight control only results in a 4-5% change in control between motoring and pumping, versus the typical competitor product change of 10%.

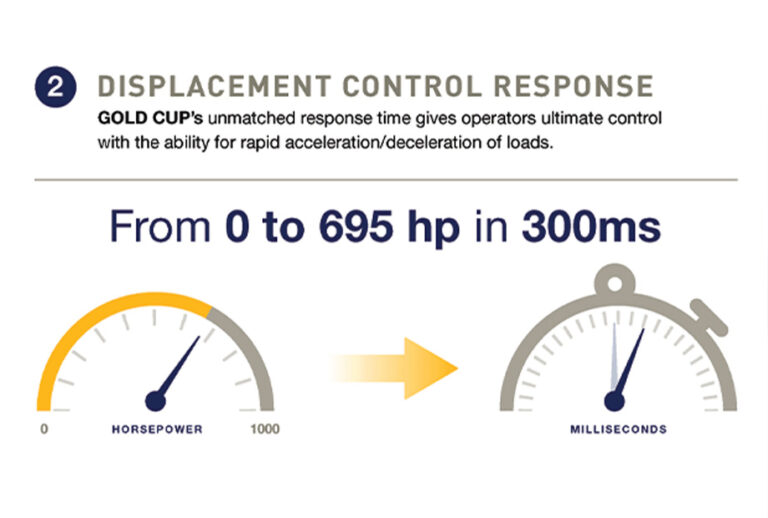

- Displacement control response can ramp up from 0 to 695 hp in 300 ms.

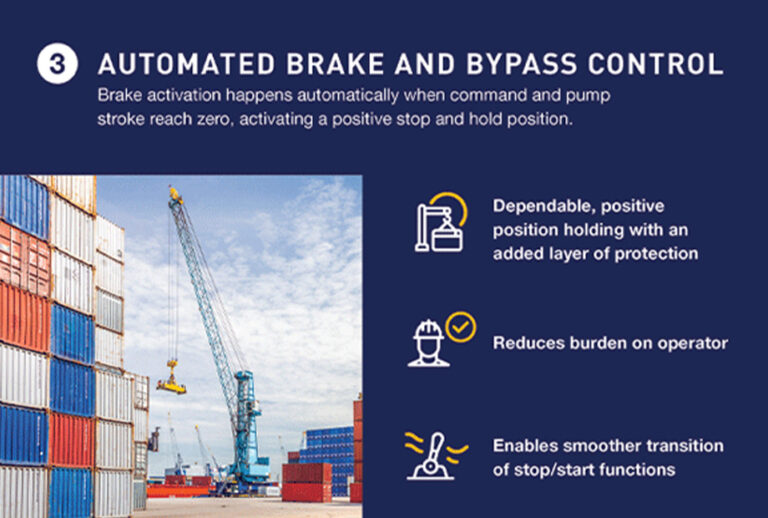

- Automated brake and bypass control provides smoother stop and start transitions, reducing the operator burden.

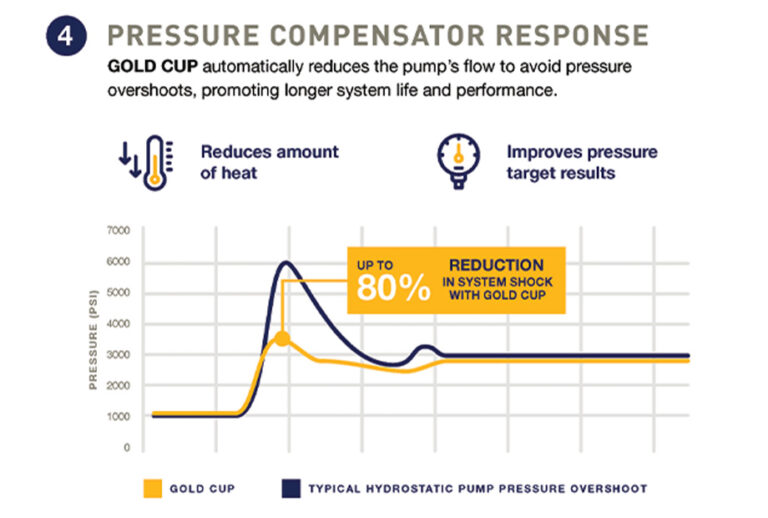

- Pressure compensator response reduces heat and results in an 80% reduction in system shock.

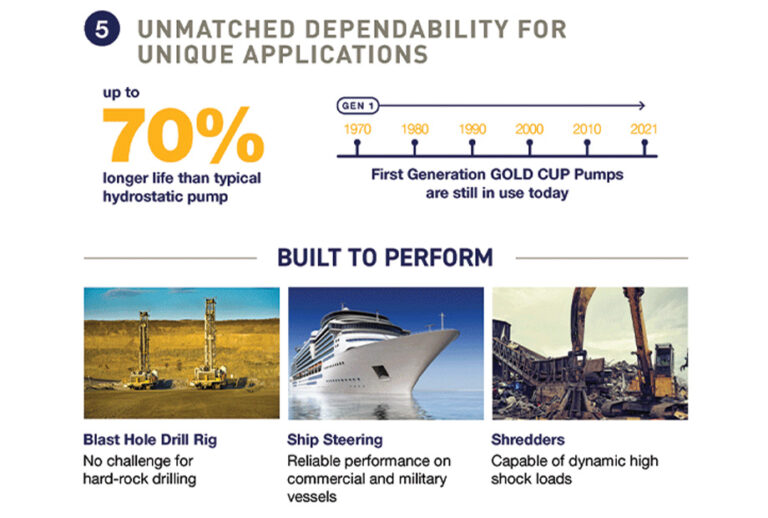

- 70% longer life than a typical hydrostatic pump. Since Gold Cup’s inception over 50 years ago, these first-generation pumps and motors are still in use.

- Numerous certifications and qualifications ranging from military-grade to ATEX.

For more details, check out Parker’s hydraulic pump and power system’s “You probably didn’t know about Gold Cup” infographic series below.

»

»

Precise, tight control

»

»

Displacement control response

»

»

Automated brake and bypass control

»

»

Pressure compensator response

»

»

Dependability for unique applications

»

»

Certified and qualified

This article was contributed by Parker Hannifin’s US Hydraulic’s Team. Licensing for the images came with permission from the Parker Hannifin Media Manager collection.

We are official suppliers for Parker hydraulic equipment and components and trusted by customers in 130 countries worldwide! How can we help?

Discover more free content from Parker in our Fluid Power Technical Knowledge Hub…

Check Valves are the Unsung Heroes of Fluid Power

Check valves are unseen and undervalued. These valves are found in just about every mobile and industrial hydraulic system on the planet. Simply put, if there’s a pump, most likely you will find a check valve.

Considering its wide use, engineers, maintenance technicians and even end users should have a basic understanding of the function that this essential component serves in their systems.

Learn MoreAdvantages of Helical Hydraulic Actuators in Heavy-Duty Applications

Hydraulic actuators cause engineered equipment to move, slide, rotate and lift by converting energy from pressurised fluid and hydraulic power units.

Depending on the type of machinery involved and the desired movement needed, there are a variety of linear and rotary actuators available to best match the needs of the designer.

Learn MoreThe Parker V16 Variable Displacement Motor

Parker V16 Series is the next generation of variable displacement, bent-axis motors. It further develops Parker’s well-known V12 and V14 hydraulic motor series. It is designed for both open and closed circuit transmissions focusing on high-performance machines and demanding mobile applications.

Here’s three reasons to choose this efficient hydraulic motor for your mobile application.

Learn More