Follow these hints and tips to avoid unnecessary problems and systems downtime when assembling your hydraulic equipment…

Tip 1

Most importantly – maintain cleanliness; contamination is the reason for many hydraulic problems.

Tip 2

All openings in the reservoir should be sealed after cleaning.

Tip 3

No grinding or welding should be undertaken in the area where hydraulic components and systems are being installed. All cylinder, valve, pump and hose connections should be sealed and/or capped until just prior to use.

Tip 4

Mineral spirits should be kept in safety containers.

Tip 5

Air hoses can be used to clean hydraulic fittings and other components. However, the air supply must be filtered and dry to prevent contamination of the parts. Read our guide on air contamination here.

Tip 6

Examine pipe fittings and hose assemblies prior to use to ensure that burrs, dirt and/or scale are not present; all pipe and tubing ends should be reamed to prevent restriction and turbulent flow.

Tip 7

Never use Teflon tape on straight thread connections.

Tip 8

When installing hydraulic pumps or motors, always align coupling halves as closely as possibly, within 0.007 inch. When using flexible couplings, follow the manufacturer’s recommendations or allow 1/32 to 1/16 inch clearance between the coupling halves.

Tip 9

Do not drive couplings on pump or motor shafts; they should be a slip fit or shrunk on using hot hydraulic oil.

Tip 10

Always use a dry spray-on lubricant on splines when installing. This prevents wear and adds to the useful life of the splines. Moreover, when using double universal joint couplings, the shafts must be parallel and the yokes must be in line.

Tip 11

When installing V-belt pulleys on pumps or motors, line up both pulleys as closely as possible. Always install the pulleys with a minimum amount of overhang as close to the pump or motor face as possible – this increases bearing surface life.

We’re a hydraulics ‘hub’, offering thousands of possibilities… how can we help?

Discover more Free Educational Content including more hydraulic tips and tricks from our Fluid Power Technical Knowledge Hub…

The Ultimate Hydraulic Oil Guide

Hydraulic oil is the life-blood of a hydraulic system and yet it is so often overlooked.

It is crucial that hydraulic oil is regularly checked and maintained. Find out how in our ultimate guide to hydraulic oil…

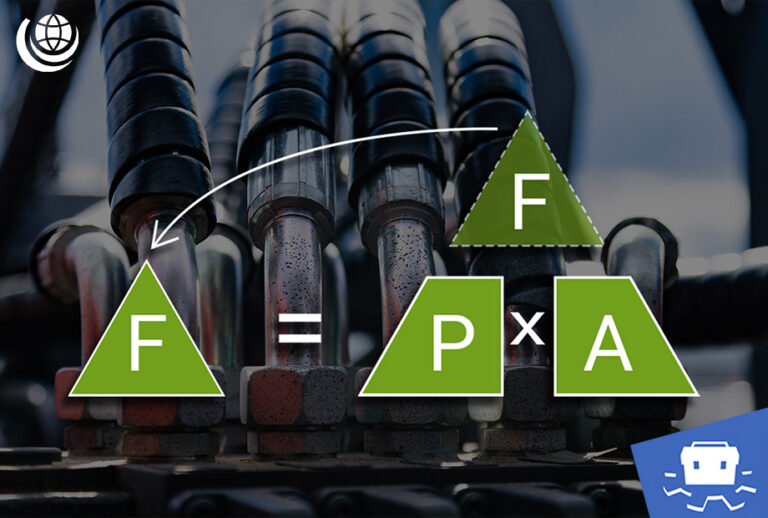

Learn MoreAn Introduction to Hydraulic Pressure and Flow

An understanding of the key principles of fluid dynamics is, essential for anyone who wishes to build or maintain hydraulic systems.

One of the first concepts that must be understood is how physicists quantify the movement of fluids, namely flow.

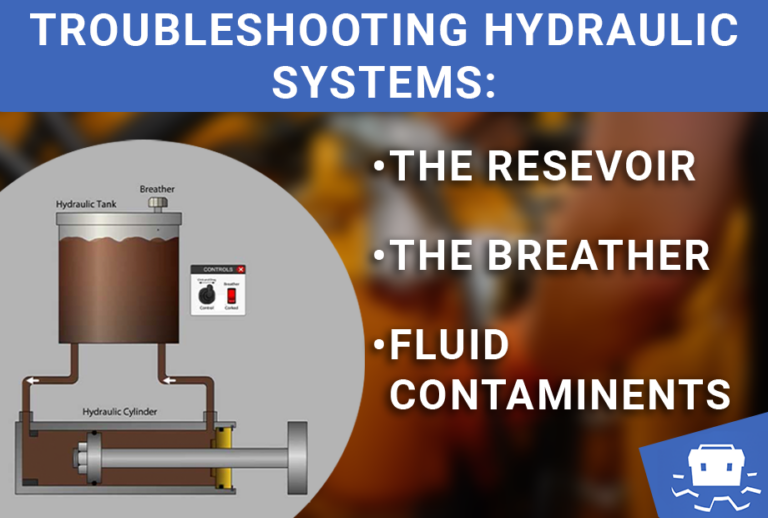

Learn MoreTroubleshooting Hydraulic Systems: The Reservoir, The Breather and Fluid Contaminents

The hydraulic reservoir plays an important part in hydraulic circuit design – storing hydraulic fluid when it isn’t being pushed through the hydraulic system.

While a “fluid storage tank” might seem like a very simple concept, the design and implementation of the reservoir is very important.

Learn More