From around the corner to the other side of the world, seven days a week, Hydraulics Online is contacted by customers from all walks of life in a wide variety of industries.

Some customers know precisely what they are looking for; others need all the support they can get. Some are innovating, creating new hydraulic engineering designs and solutions for tomorrow; others desperately need a replacement part ‘yesterday’.

One thing is constant, no matter the customer and the country that they’re contacting us from: each enquiry requires a different solution as you’ll see from the snapshot of hydraulics examples that we’re sharing here…

»

»

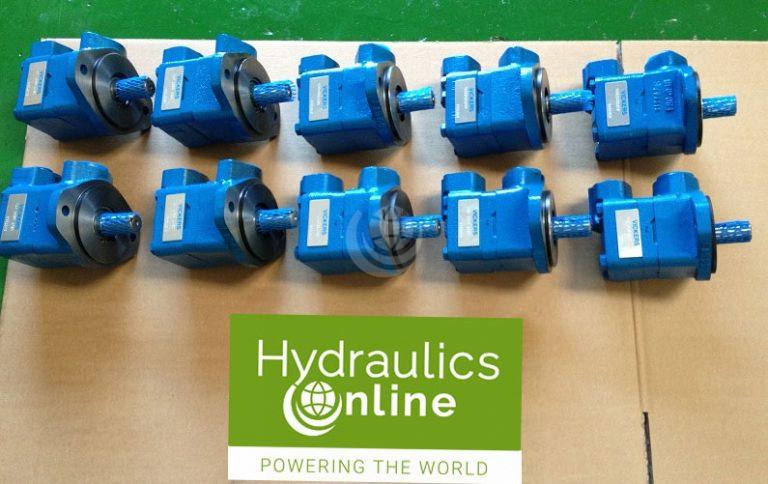

Customer: Marine Services Supplier to the Global Oil and Gas Industry

Task: Hydraulics Online were contacted following the failure of a hydraulic pump on the customer’s vessel in New Zealand.

Solution: A replacement Vickers vane pump was available “ex stock” and collection was arranged for the following morning to take it to London, Heathrow Airport – the beginning of a 11,500 journey. It’s a small world…

»

»

Customer: Original Equipment Manufacturer – Alternative Energy Supply

Task: Hydraulics Online was approached to design a complete hydraulic system for an OEM producing wind turbine masts.

Solution: The system was designed for installing wind turbine masts into remote locations. The system was commissioned, performed well and the customer has since placed repeat orders.

»

»

Customer: Steelworks

Task: Hydraulics Online were contacted to locate an hydraulic pump that the customer had been told was no longer available.

Solution: The Bosch Racine pump was identified and an original, new unit was located and shipped over from the U.S.A. within 48 hours. Downtime was minimised and further orders are pending for additional new hydraulic pumps – keeping re-engineering costs to an absolute minimum.

»

»

Customer: Steel Rolling Mill

Task: A new overseas customer tasked Hydraulics Online to quote for the supply of 8 Bosch Rexroth pump-motor sets.

Solution: The Bosch Rexroth pump-motor sets were quoted but given the long lead time we also proposed a direct equivalent – Danfoss Series 90, 75 kw pump-motor sets at half the lead time of the original units. The customer accepted the alterative and the Danfoss pump-motor sets were shipped as agreed and worked perfectly from day one.

»

»

Customer: Specialist Vehicles Manufacturer

Task: Provide a bespoke hydraulic system to suit the customer’s own specialist and diverse, custom applications.

Solution: The basic functional description was taken from the customer against which the Hydraulics Online design team proposed a complete hydraulic system which was “fit for purpose” from the outset; meeting budget and specialist business design needs without the need for any further re-engineering.

»

»

Customer: Small OEM within Construction Industry

Task: Design and supply a complete hydraulic drive system for a multiple function prototype machine within the construction industry.

Solution: Hydraulics Online designed and supplied a complete power and drive-train system, enabling the customer to take their product to market competitively priced and with functionality that delivered real market advantage.

»

»

Customer: Renewable Energy Engineers

Task: As our customer’s preferred hydraulics company, Hydraulics Online were approached to provide a suitable hydraulic system for the operation of a sluice gate in a remote location within the water power generation industry.

Solution: Hydraulics Online proposed, built and supplied a suitable self-contained, portable hydraulic power pack / hydraulic power unit system thus enabling our customer to fulfil their contract requirements.

»

»

Customer: International Waste Management Services Company

Task: Hydraulics Online received a brief email enquiry for a bespoke 3-stage telescopic, double-acting hydraulic cylinder.

The Solution: After numerous telephone calls and emails Hydraulics Online’s hydraulic engineers were able to determine the exact specification against which the customer placed their order. The 3-stage telescopic, double-acting hydraulic cylinder was completed within the required time frame.

»

»

Customer: Power Transmission Equipment Manufacturer

Task: Provide a complete hydraulic system and bespoke cylinder for a tipping hopper application.

Solution: Hydraulics Online specified and supplied a complete hydraulic system including hydraulic power pack and hydraulic actuator. Custom hydraulic cylinders and mounts were made and the whole package was delivered within budget and time constraints.

Take a deeper dive into the world of Hydraulics Online, by exploring more high-profile and in-depth hydraulics examples and case studies!

»

»

Customer: Power Transmission Engineering Products Company

Task: Hydraulics Online were contacted after a blue-chip client’s critical gearbox / hydraulic motor had failed, our customer having been unable to source a replacement hydraulic motor from their existing suppliers within an acceptable lead time.

Solution: The hydraulic motor was identified immediately and an identical, replacement hydraulic motor was sourced and air-freighted within 48 hours to minimise downtime for the end customer.

»

»

Customer: National Household Power Generation Company

Task: The team were contacted following the failure of the main hydraulic starter (radial piston) motor on a LM6000 GT package. The original unit, a Bosch-Rexroth motor, was on a long lead time.

Solution: A hydraulic engineer visited site within the hour; identified the hydraulic motor and specified a suitable equivalent Italgroup hydraulic motor. This was delivered to site the same day, minimising downtime once again.

»

»

Customer: High Quality Plastic Card Manufacturer

Task: Hydraulics Online were called to site to fault-find a critical piece of hydraulic equipment and provide a speedy solution to production problems.

Solution: An off-line, compatible, high pressure (700 bar) hydraulic system was installed enabling the customer to meet production targets and agreed service levels and avoid severe third-party penalties were avoided. Win, win, win!

»

»

Customer: Petroleum Refinery Company

Task: Hydraulics Online conducted a joint site visit to examine old hydraulic systems in need of a major overhaul. The area in question was a highly explosive ATEX Zone 1 application which also required all solenoid control valves to be replaced on key hydraulic power units.

Solution: Hydraulics Online specified and delivered the required hydraulic components within the customer’s time and budget constraints and have since supplied additional ATEX equipment on numerous occasions.

»

»

Customer: Major OEM of Construction Equipment

Task: Hydraulics Online were asked to design and quote for a special high-flow low pressure, low-flow high pressure hydraulic power pack / hydraulic power unit for a system fitting clutches into gearboxes on construction equipment.

Solution: Our team designed and built a bespoke mini-hydraulic power unit with a 2 bar low-pressure system, 250 bar high pressure system. The unit is now installed and operational on our customer’s main production line.

»

»

Customer: 24/7 On-Site Hydraulic Service and Installation Company

Task: An old, failing, pneumatic and manually- operated 6 tonne press was part of a critical production line and needed to be converted to a hydraulic function with a simple control panel. Delivery was critical.

Solution: Hydraulics Online engineers designed, built and supplied the hydraulic power pack within three working days. The unit was installed and commissioned without a hitch and within less than a week had been proven to have increased output.

»

»

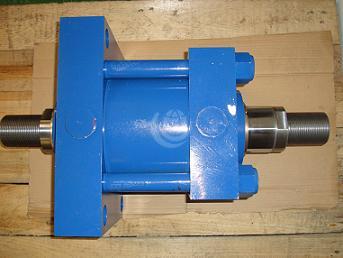

Customer: Management, Engineering and Procurement Services Company to Offshore, Sub-sea and Oil and Gas Industries

Task: The customer asked Hydraulics Online to specify and quote for a bespoke application requiring a through-rod (double-rod) hydraulic cylinder / actuator. The design parameters were given for a competitor’s product.

Solution: Hydraulics Online quoted for, and then supplied, an equivalent bespoke through-rod hydraulic cylinder with exactly the same technical specification but with a much more attractive price tag and lead time for the customer.

»

»

Customer: Multi-National Production Facility

Task: An old, failing, critical piece of production equipment was employed on a continuous 24/7 run. But the old hydraulic circuits and leaking, obsolete valves meant that the customer spent more time on fixing regular breakdowns than on production itself.

Solution: Hydraulics Online were asked to attend site and designed a far simpler, yet more cost-effective, solution to upgrade the hydraulic power pack. Work was completed on schedule and a backlog in production was tackled and the customer is now able to complete orders on time.

»

»

Customer: Original Equipment Manufacturer of Mobile Harvesting Equipment

Task: Hydraulics Online were approached to review the customer’s existing system design and to highlight areas for possible improvement.

Solution: A number of areas were identified and a revised systems design was proposed. The major changes centred on a new pump motor drive system together with all directional controls. These were implemented and, as promised, delivered significant improvements to systems’ performance and efficiency.

We are the first choice for customers in over 130 countries worldwide, supplying a vast selection of hydraulic brands and components. You are guaranteed impartial, technical advice and optimal solutions. Every time.

»

»

Customer: Luxury Overseas Yacht

Task: To identify, source and supply a replacement main steering drive hydraulic pump.

Solution: Despite there being no identifying marks or plates on the worn-out hydraulic pump, Hydraulics Online recognised the unit from pictures emailed to the team. An identical replacement pump was on long lead time, but Hydraulics Online sourced a direct equivalent which was then received by the customer within 48 hours – massively minimising down time.

»

»

Customer: OEM to the Livestock Industry

Task: To help with hydraulic systems redesign to enable a move to a direct hydraulic drive system.

Solution: Hydraulics Online successfully completed the hydraulic systems redesign and suggested further changes to enable greater efficiency and cost-effectiveness of all hydraulic equipment used within their product range. The result: greater reliability and productivity of an already “tried and tested” vehicle, bringing real competitive advantage to our customer.

»

»

Customer: National Distributor of Industrial Maintenance and Repair Products and Services

Task: Hydraulics Online engineers were called to site and tasked with fault-finding on a production line where all activity had ceased.

Solution: The cause, an obsolete hydraulic pump unit, was identified and a new, modern, more readily available unit was proposed, sourced and flown into the UK within a 48 hour period.

»

»

Customer: Household Name in Frozen Food Manufacturing

Task: Three Continental PVR50 hydraulic vane pumps had failed on main production lines and were beyond economical repair. New hydraulic pumps were required urgently to restore production.

Solution: Hydraulics Online sourced and imported the hydraulic pumps within 2 days. They were then delivered to site the same day, enabling downtime on the production line to be kept to a minimum.

»

»

Customer: Offshore Fishing Vessel

Task: The customer’s trawler was stranded, unable to operate and therefore earn revenue. Hydraulics Online were approached to supply an alternative hydraulic motor to a competitor’s product which was on a long lead time.

Solution: Hydraulics Online sourced an “off the shelf” equivalent motor which was then flown into UK within 48 hours, thus minimising the loss in revenue to the customer. No major re-engineering was required.

»

»

Customer: The University of Edinburgh

Task: To provide a hydraulic system (as a concrete testing machine) for destruction tests within the construction industry.

Solution: Hydraulics Online specified and built a suitable high-pressure hydraulic power pack / hydraulic power unit including actuators which was then supplied to the customer within tight time and budget constraints.

»

»

Customer: Household Name Distribution Company

Task: Hydraulics Online were asked to identify an unmarked hydraulic power pack / hydraulic power unit and to specify a new, more efficient, cost-effective system.

Solution: The team submitted a proposed specification and quotation. The bespoke hydraulic power units were built and delivered within the customer’s required shutdown / maintenance period and all are now installed and working in a busy distribution depot.

»

»

Customer: Shredding and Data Disposal Company

Task: Hydraulics Online were contacted to design and supply an efficient hydraulic system to run a mobile compactor and crusher.

Solution: Hydraulics Online proposed a hydraulic system using Italgroup radial piston motors. The vehicle was delivered to Hydraulics Online’s premises and our team installed the PTO-driven power source and hydraulic control valves. A second vehicle has since been fitted to the same specification.

»

»

Customer: Bespoke Construction and Engineering Company

Task: Hydraulics Online were asked to design and supply a complete hydraulic system for use in a disabled household to open and close loft and office access doors hydraulically.

Solution: A suitable hydraulic system was designed, built and supplied with a complete hydraulic power pack including all relevant hydraulic hoses and fittings. The hydraulic system is now installed and working on a daily basis.

It's all about YOU. Whether it’s a small one-off job, or an enduring relationship delivering complex hydraulic services, we want you to feel delighted that you have found us.

»

»

Customer: Compactor Manufacturer

Task: Hydraulics Online were consulted to help simplify an existing hydraulic circuit with the specific objectives of increasing reliability whilst reducing purchasing costs.

Solution: The team completed the hydraulic system redesign, within budget. As a result, the customer chose to rationalise their supplier accounts for their entire product range and made Hydraulics Online their chosen hydraulics company and single source of supply with a competitive pricing structure and, in many cases, reduced costs.

»

»

The Customer: Key Production Plant to the Brewery Industry.

Task: To re-engineer and supply a more efficient hydraulic power pack, within 3 days, as a major production line was down.

Solution: Within 2 hours one of our team attended site and specified a new system. The customer ordered immediately and the power pack was built, tested and installed within 72 hours; downtime and lost production was minimised. Within a further 48 hours all lost production was recovered and new productions was ahead of schedule thanks to greater efficiency from the hydraulic power pack.

»

»

Customer: Alternative Energy Power Company

Task: Hydraulics Online were approached as the customer’s previous hydraulic supplier had failed to meet expectations. The customer supplied outline requirements and asked Hydraulics Online to propose a brand new hydraulic system.

The Solution: A bespoke hydraulic power pack was designed and built with many modifications to the original, inherited specification. This resulted in a much more stable and controllable system which was far more suitable to the application.

»

»

Customer: Steel Works

Task: Hydraulics Online were asked to provide a new hydraulic system capable of moving a 7000kg tool slide in a controlled and timed “stop-start” movement, and also to lift and lock the associated mandrils as required in a continuous cycle.

Solution: The team designed a complete bespoke hydraulic system proposing improvements to the customer’s original proposals and incorporating proportional valve control of the 100- and 80 litre/minute pumps that were fitted to the power pack. The complete system was manufactured, installed and commissioned without a hitch!

»

»

Customer: Leading Manufacturer of Concrete Products, Ireland

Task: Hydraulics Online were asked to design a complete hydraulic system that would meet the customer’s exact requirements.

Solution: A full system was designed and supplied comprising single-acting, telescopic lift cylinders and complete power pack. It was successfully installed and commissioned and is now in use in daily production.

»

»

Customer: Power Generation Control Systems and Package Maintenance Company, Middle East

Task: To design and supply a highly efficient hydraulic lubrication filtration system for multiple gas turbine power generation systems to power a desalination plant within the Middle East.

Solution: Hydraulics Online proposed and delivered multiple low- and high- pressure Duplex high-flow, high efficiency hydraulic lubrication filtration systems – thus enabling a multi-million pound installation contract to be successfully completed.

»

»

Customer: Leading Producer of Concrete Products to Civil Engineering, Construction and Agricultural Sectors

Task: Hydraulics Online were approached to replicate an existing, ageing hydraulic system that was no longer available.

Solution: Despite working with minimal information, the team proposed a much more modern and efficient hydraulic system. This enabled the customer to order and install multiple sets of hydraulic equipment, realising major cost savings in the process.

»

»

Customer: Leisure and Fairground Attraction Provider, UK

Task: Our customer was due to attend a prestigious national event when their attraction’s main hydraulic drive failed. The identical replacement product was on a four-week lead time, meaning that the ride would be out of operation for the whole event and all revenue lost.

Solution: Hydraulics Online proposed a suitable direct replacement, sourced from Italgroup, and this was flown into the UK within 48 hours, with no re-engineering required. The customer was able to meet their commitment for the major weekend event and, critically, to protect revenue. Happy days!

»

»

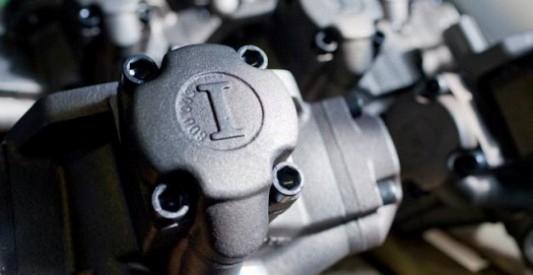

Customer: Transport Industry

Hydraulics Online were approached by one of the most respected names in the global transport industry and asked to quote for regular supplies of Vickers hydraulic vane pumps. And the rest, as they say, is history.

We love working with original equipment manufacturers, helping them to create a quality product and strengthen their brand. But given that this customer’s vehicles operate throughout the world, we’re rather proud to be “doing our bit” to keep the world moving too – quite literally!

We’re a hydraulics ‘hub’, offering thousands of possibilities… how can we help?

»

»

Hydraulic Power Pack Design

We love the vast array and contrast of applications and hydraulic projects that we are involved with every day. Take our hydraulic power pack design services – one week we’re designing the system to make the first UK Concorde “droop nose” work again and the next we’re working on a project to make mud bricks in Africa.

A new customer approached the technical team with a proposed design for a machine to make mud bricks to aid the construction of huts and basic housing in Africa; the whole project was being funded by a local charity/welfare group. The machine was to compress the mud in large, brick-shaped moulds before the bricks were then baked and used to build the huts.

Drawing on their extensive technical knowledge, our team suggested some modifications to the customer’s original suggestions before building a hydraulic power pack design that would meet the system requirements exactly.

The picture above shows the complete machine and the hydraulic power pack in situ and below we have a “thank you” from the customer:

“Thanks for all your support and your prompt replies to my queries and for providing the best hydraulic power pack design and equipment… unlike the substandard components from China used by others. Our client is very happy with the overall performance of the equipment.”

»

»

Hydraulic Power Packs for OEMs

We recently had an enquiry from an original equipment manufacturer (OEM) in New Zealand; the company were looking for a hydraulic power pack manufacturer in the UK… to provide a quality, British product. The team at Hydraulics Online have a wealth of experience in building and supplying hydraulic power packs, so we knew exactly what design and specification would work best in the customer’s application (a single-acting, 12v DC hydraulic power pack with flow control) and were able to quote instantly. The customer requested a trial power pack, which we proceeded to build and ship the same day.

“We approached Hydraulics Online 18 months ago for assistance in the design and supply of bespoke hydraulic control systems. As a result of their vast technical knowledge and wide product range available, we were able to develop a system which was both competitively priced and completely tailored to suit our application.

Since our initial projects with Hydraulics Online, we have worked together to develop further systems to complement our product range, further heightening our position in the market place. They have also been a valuable technical partner assisting our engineering personnel on site with issues faced in the field. Overall, a valuable tool for any business. – An appraisal from another satisfied OEM customer.”

»

»

Leading Global Energy Company

Hydraulics Online were contacted late on 17th June with a requirement for a number of Denison proportional amplifier cards. They were needed for one of our customer’s exploration rigs in Angola and, as is often the case, it was urgent… there was no time to spare.

The customer was quoted the following morning, the lead time being 8-10 weeks. The customer placed their order on 20th June, acknowledging that their target date for delivery (4th July) had been somewhat ambitious and would not be achieved. Or so it had it seemed.

Keen to improve on delivery if at all possible, the sales team approached a potential alternative supplier and successfully negotiated expedited delivery of the goods within the same week. Cue one happy customer who took delivery of their Denison proportional amplifier cards on 30th June… 4 days ahead of their original, hugely ambitious, schedule!

»

»

Offshore and Marine Hydraulic Services

The Hydraulics Online sales and technical team have proven their worth as far as marine hydraulics and offshore applications are concerned; an increasing number of businesses are looking our way to source marine and offshore hydraulic equipment… and often they are up against incredibly tight deadlines too, i.e. they really needed it “yesterday”!

A large offshore oil company enquired about a Commercial Hydraulics P365/P330 tandem pump – they were in a breakdown situation on one of their accommodation rigs. The Commercial pumps were on an 18-week lead time, not the news the customer wanted to hear, but the good news was that we could offer a direct equivalent from stock: a quality product, built and tested here in the UK. The customer placed their order immediately. The pump was built, tested and ready for dispatch within 24 hours and then transported by helicopter to its new home on the accommodation rig the following day.