Overheating is one of the most common issues in a hydraulic system and is caused by an increase in the hydraulic oil temperature.

Hydraulic oil temperature beyond 82°C is likely to damage the hydraulic component seal compounds; accelerating oil degradation. You can usually tell if the temperature is too high, as the viscosity will be too low for the hydraulic components. Viscosity can also be negatively affected in temperatures below 82°, depending on the oil’s viscosity index. To ensure a stable oil temperature, the hydraulic system must be able to dissipate heat much faster than it is built up.

How to prevent overheating

The two most common ways of preventing overheating in your system are to either reduce the hydraulic oil temperature or increase heat dissipation.

Heat dissipation occurs in the hydraulic reservoir. By checking the reservoir, you can ensure that the fluid level is correct. And if it is too low, simply fill it to the correct level. You must also make sure there is nothing obstructing the air flow into the reservoir. For example, this may be a build-up of dirt or debris.

Heat exchangers

When examining heat exchangers, make sure that the core is not blocked. The heat-exchanger relies on the flow-rate and temperature of the hydraulic oil and the coolant in order to disperse heat suitably. If you experience issues with the cooling circuit then they need to be replaced.

You can use an infra-red thermometer to ensure that the performance and oil flow-rate of the heat exchanger is optimal.

Leakage

If the pressure in a system drops, heat is being generated. Likewise, if any of the components in the system are leaking, they will increase the heat generation. You should be able to identify any components that are leaking internally. They could be anything from a cylinder leaking fluid to a valve that hasn’t been adjusted properly.

If a relief valve is below, or too close, to the pressure setting of a pressure-compensator in a closed-centre circuit, it can lead to increased heat generation and the system pressure cannot reach the pressure compensator setting. Subsequently, the component will continue to move oil thorough the system, passing over the relief valve, which produces heat.

We are the first choice for customers in over 130 countries worldwide, supplying a vast selection of hydraulic brands and components. You are guaranteed impartial, technical advice and optimal solutions. How can we help?

Discover more Free Educational Content from our Fluid Power Technical Knowledge Hub…

How to size a Hydraulic Cooler…

Did you know that overheating is second in the list of most common problems with hydraulic equipment? Leaks rank first.

As a means of power transmission, hydraulics have many advantages, but overall efficiency is NOT one of them.

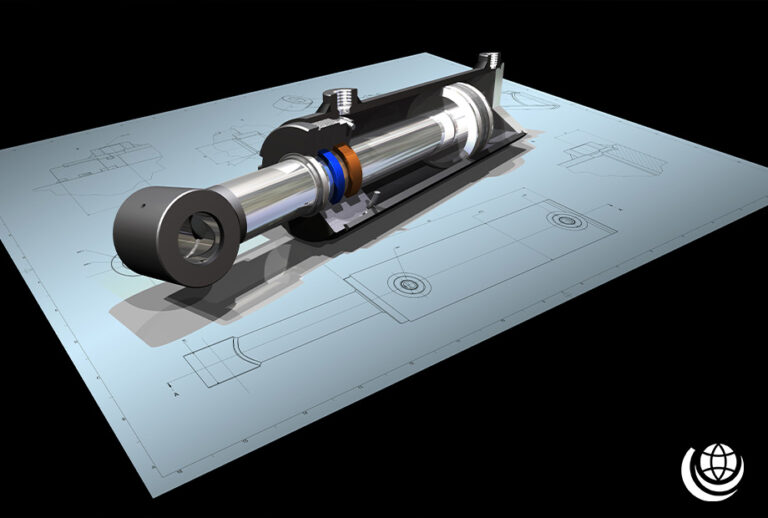

Learn MoreThe Vital Role of Hydraulic Cylinder Seals

Hydraulic cylinder seals are commonly found in applications where components are exposed to liquids. They play a vital role within the hydraulic system, as they enable the transfer of liquid power into linear motion.

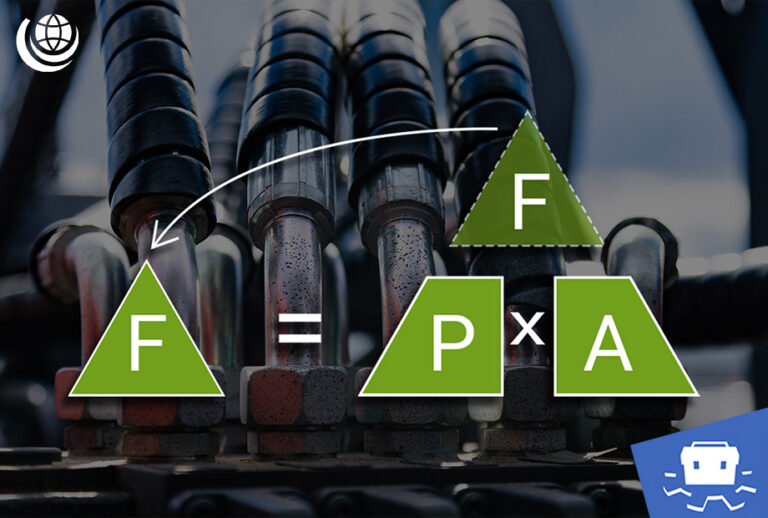

Learn MoreAn Introduction to Hydraulic Pressure and Flow

Hydraulic systems are based on the principles of fluid dynamics; the important branch of science deals with the movement of fluids. An understanding of the key principles of fluid dynamics is essential for anyone who wishes to build or maintain hydraulic systems.

Learn More