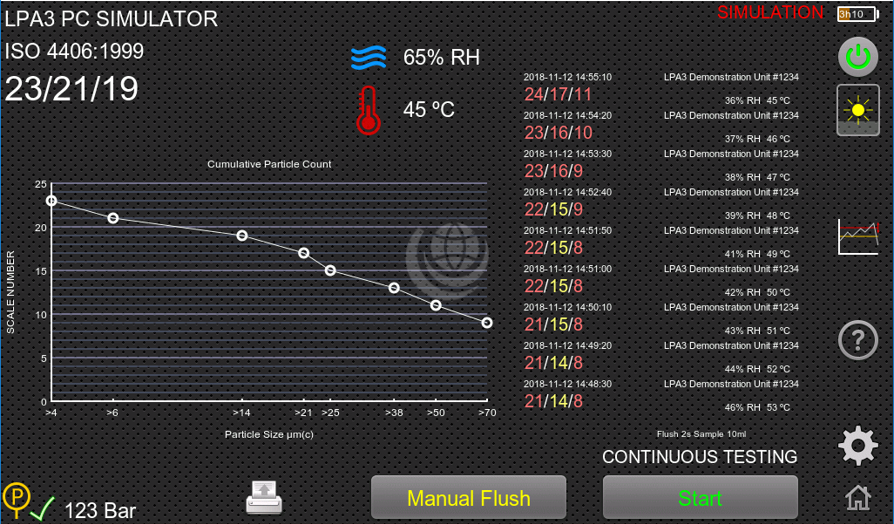

The centrepiece of the new LPA3 is its new 10.1” (25.7 cm) full-colour touch-screen display with QWERTY keyboard.

Its capacitive screen responds instantly to light fingertip touches for a reliable and responsive performance with no need for a stylus. It is also highly durable and delivers a sharp high-resolution image on its 1024 x 600m display.

A fully customisable home screen interface enables operators to tailor the display to show the precise information they need at-a-glance. It also comes with multi-lingual support and regional options such as imperial/metric conversion.