A worldwide leader in hydraulic filtration and contamination monitoring technology, MP Filtri UK offers a comprehensive range of innovative products that protects and enhances the performance of equipment; reduces downtime, service and maintenance costs; and lowers the risk of system failure.

Hydraulic systems are integral to the way we live today – with critical applications everywhere: from aerospace to agriculture, energy to manufacturing. Most hydraulic failures are caused by particle contamination, and the quality of filtration is therefore the most important factor in a hydraulic machine’s long-term health.

Part of the MP Filtri Group based in Milan, Italy, which has nearly 60 years’ experience in creating market-leading filtration products, the UK operation acts as the company’s fluid contamination monitoring arm – designing and manufacturing a range of high-tech hydraulic particle counters and accessories for portable, in-line, and laboratory applications.

Key products and support materials include:

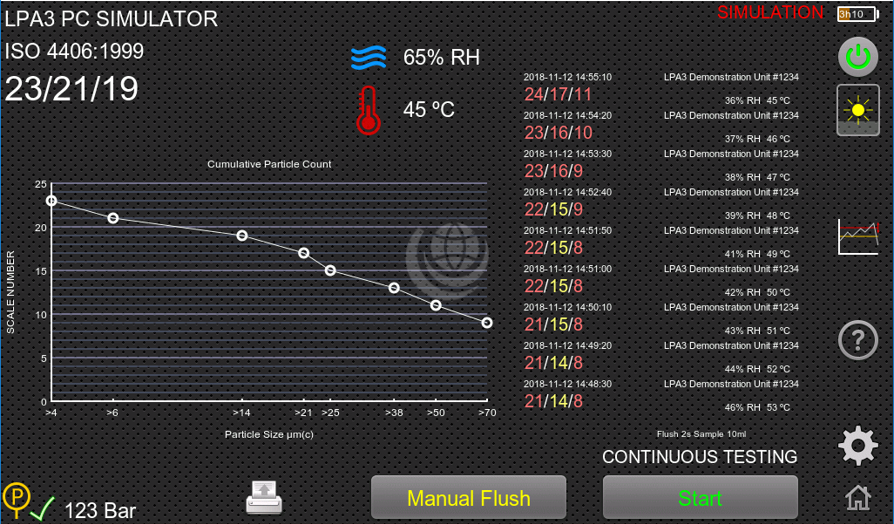

- The LPA3 portable particle counter, featuring the latest optical and photodiode technology. It delivers a fast and accurate hydraulic health check – enhancing the reliability and longevity of hydraulic systems.

- The ICM 2.0 Inline Contamination Monitor, which automatically measures and displays particulate contamination, moisture and temperature levels in various hydraulic fluids – providing vital early warning of particle build up. A wifi-enabled version – the ICM 4.0 – is also available.

- New CMP View analytical software, which delivers all the contamination data you need at-a-glance on a single screen. Eye-catching and simple to master, the software makes analysis easier than ever before and is compatible with our full range of particle counters.

- A comprehensive range of high-performance filtration products, including: Suction filters and strainers, return filters, Low and Medium pressure filters, High-pressure filters, spin-on filters, return/suction filters, stainless steel filters, and a comprehensive selection of accessories.

- A wide choice of power transmission products including bell housing and couplings that are tailor-made for maximising the power from the electric pump to the hydraulic motor – delivering peak performance and efficiency.

Please contact us for further technical guidance or if you cannot see the filters and hydraulic equipment that you need listed below – we’ll be happy to help!

MP Filtri Product Range

MP Filtri Filtration Accessories

MP Filtri High Pressure Filters

MP Filtri LMP Low & Medium Pressure Filters

MP Filtri Offline Filtration Units

MP Filtri Particle Counters

MP Filtri Return Filters

MP Filtri Return Suction Filters

MP Filtri Spin-On Filters

MP Filtri Stainless Steel Filters

MP Filtri Suction Filters/Strainers

MP Filtri News and Insights

Contamination Management

Up to 80% of all failures on hydraulic systems are due to contaminants in the hydraulic fluid. Solid contamination is the main cause of malfunction, early degradation failure and in hydraulic systems. It is impossible to remove completely, but it can be effectively controlled by appropriate devices.

Find out moreSizing Hydraulic Filters

Choosing the right hydraulic filter depends on the characteristics of other system components and their sensitivity to contamination, as well as a number of other key factors.

Benefits of proper positioning and sizing include great system reliability, longer fluid and component life and reduced failures.

Fluid Condition and Filtration

Hydraulic fluid acts as both a lubricant and a power transmitting medium. The presence of solid contaminant particles in the liquid inhibits the ability of the hydraulic fluid to lubricate and causes wear to the components. The extent of contamination in the fluid also affects the performance and reliability of the system.

Discover moreParticle Counters Handbook

This handbook provides information and practical examples of contamination measurement technologies and particle counters in use. It covers various topics including: the importance of particle counting in preventive maintenance; an explanation of the solid contamination control device; reference standards and further details on MP Filtri’s product range.

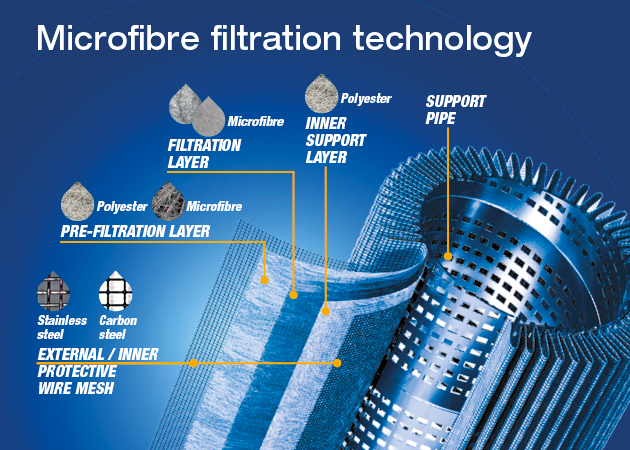

Discover moreFiltration and Element Technology

Filters are constructed by fibre interlacing. This forms different shaped and sized pathways that trap particles when the find apertures that are too small. Depth filters are generally produced with papers impregnated with either resins, metal or inorganic fibres. In inorganic fibre filtration, filtering layers are often overlapped to increase the ability of the filter to retain the contaminant at an even lower mm level.

Find out moreHydraulic System Contamination

Whether through the use of contaminated fluid or caused over time by surface wear, corrosion or cavitation, contamination is the biggest source of system failure.

It can triggered by the presence of solids, other liquids, or gases in the hydraulic fluid. Here we look at the effects of each, best practice for prevention and how to remove contaminants already in your system.

Subscribe to our newsletter to receive more free technical guides, product insights and resources…

Get in Touch

"*" indicates required fields