With a single-acting cylinder when fluid flow is applied to a port in the closed end, the shaft extends until the collar or piston reaches the shaft end.

When an external weight or load is placed on the shaft, the shaft will retract into the chamber until the piston or collar reaches the closed end. The cylinder will produce an output force at the shaft end in proportion to its internal closed end area multiplied times the pressure potential of the fluid power system.

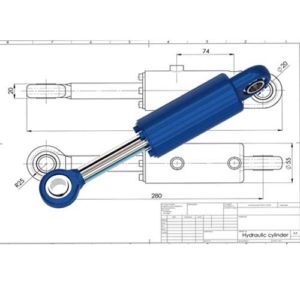

We can supply custom design single-acting cylinders tailored to your specific application and operating parameters – just complete our Hydraulic Cylinder Design Form with as much detail as you can, and we’ll then be in touch to confirm your requirements in full.

Product Categories

Can’t find what you’re looking for? Contact us.

Products

Can’t find what you’re looking for? Contact us.