A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. It generates flow with enough power to overcome pressure induced by a load.

Revisiting the basics of hydraulics

Before we continue our introduction to hydraulic pumps by looking at the different types available, it is worth reminding ourselves how hydraulic systems work and the role that a hydraulic pump plays within the system.

Hydraulic systems are designed to transmit power in a controlled way through the use of pressurised liquids. We can trace the use of hydraulic systems back to the Ancient Greeks, but the father of modern hydraulics is Blaise Pascal – a French mathematician who, in 1653, proved that when there is an increase in pressure at any point in a confined fluid, there is an equal increase at every other point in the container.

Understanding this rule made it possible to design systems that use hydraulics to multiply small forces into much bigger forces.

All hydraulic systems are based on this principle.

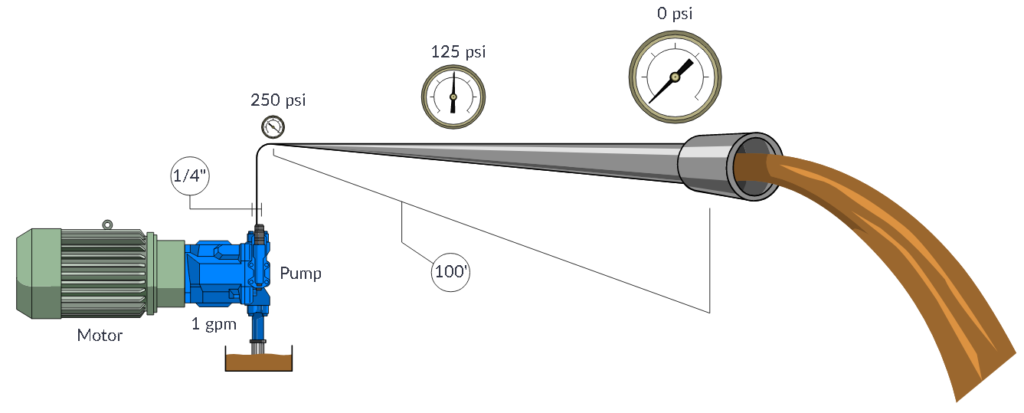

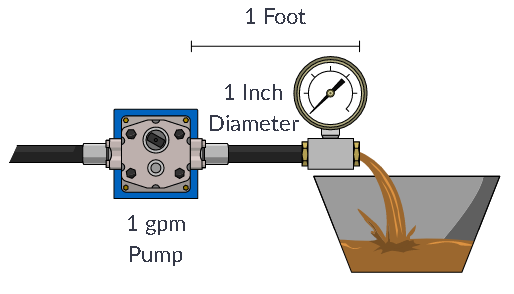

Pressure can be created in a hydraulic system by the careful design of applied forces and the gauge of pipes. Smaller hoses or pipes increase resistance and pressure – as depicted in this image, shared with permission, from LunchBox Sessions’ training platform.

How do hydraulic pumps work?

Since the function of a hydraulic pump in a hydraulic system is to generate flow, it needs to generate flow with enough power to overcome pressure induced by the load at the pump outlet.

A hydraulic pump performs two functions when it operates:

- its mechanical action creates a vacuum at the pump inlet, subsequently allowing atmospheric pressure to force liquid from the reservoir and then pumping it through to the inlet line of the pump;

- its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system.

It’s a common misapprehension that the pump has a role to play in the pressure of a hydraulic system

This is not the case; the pump does not play a role in determining the pressure applied to the hydraulic system. Instead, the role of the pump is to ensure the continued flow of fluid.

You can learn more about pressure and flow in LunchBox Sessions’ online learning. These lessons are free for subscribers to their interactive e-learning platform. Delivered in bite-size sessions, they are a fantastic online resource if you want to know more about how hydraulics and other industrial technologies work.

What are the most common types of hydraulic pumps?

The three most common hydraulic pump designs are: vane pump, gear pump and radial piston pump. All are well suited to common hydraulic uses, however the piston design is recommended for higher pressures.

Most pumps used in hydraulic systems are positive-displacement pumps. This means that they displace (deliver) the same amount of liquid for each rotating cycle of the pumping element. The delivery per cycle remains almost constant, regardless of changes in pressure.

Positive-displacement pumps are grouped into fixed or variable displacement. A fixed displacement pump’s output remains constant during each pumping cycle and at a given pump speed. Altering the geometry of the displacement chamber changes the variable displacement pump’s output.

Fixed displacement pumps (or screw pumps) make little noise, so they are perfect for use in, for example, theatres and opera houses. Variable displacement pumps, on the other hand, are particularly well suited in circuits using hydraulic motors and where variable speeds or the ability to reverse is needed.

Gear Pumps

How do hydraulic gear pumps work?

The gear pump was invented by Johannes Kepler around the year 1600. Today, gear pumps are one of the most common types of pump for hydraulic fluid power applications.

Otherwise known as positive displacement pumps, gear pumps always displace the same amount of fluid on each revolution and do not provide a way to change this volume.

Fluid carried between the teeth of two meshing gears produces the flow. The pump housing and side plates, also called ‘wear’ or ‘pressure’ plates, enclose the chambers, which are formed between adjacent gear teeth. The pump suction creates a partial vacuum. Thereafter, fluid flows in to fill the space and is carried around the discharge of the gears. Next, the fluid is forced out as the teeth mesh – at the discharge end.

Some gear pumps are quite noisy. However, modern designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles are much quieter. On top of this, they can mesh and un-mesh more smoothly.

Subsequently, this reduces pressure ripples and other, related detrimental problems.

Catastrophic breakdowns are easier to prevent with hydraulic gear pumps. This is because the gears gradually wear down the housing and/or main bushings – therefore reducing the volumetric efficiency of the pump gradually until it is all but useless. This often happens long before wear causes the unit to suddenly seize or break down.

Can hydraulic gear pumps be reversed? Yes, most pumps can be reversed by taking the pump apart and flipping the centre section. This is why most gear pumps are symmetrical.

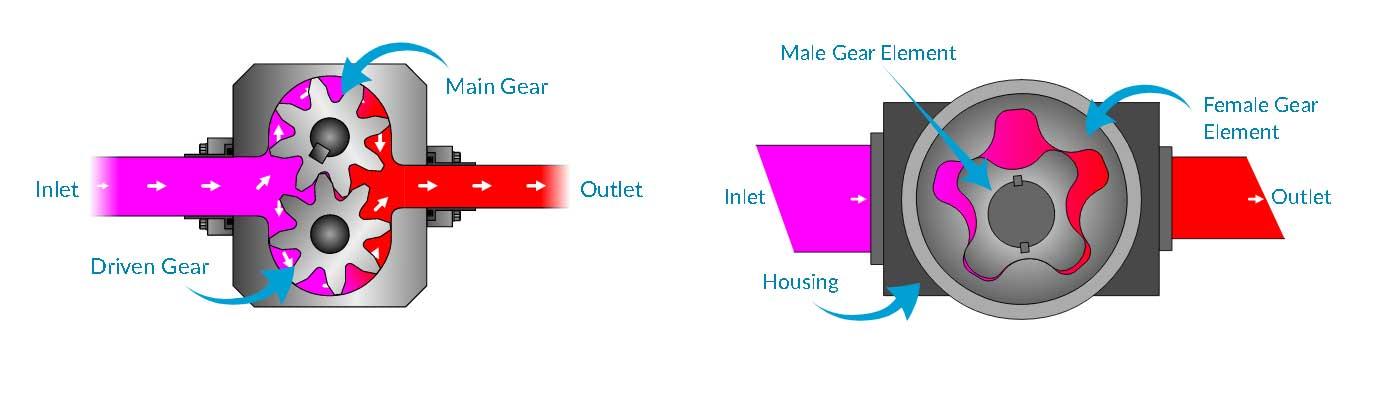

To explain more about these different types of pumps, we’ll now draw on more online hydraulics training resources from Lunchbox Sessions. In their images below the colour key is as follows: pink = vacuum pressure | blue = atmospheric pressure | yellow = low pressure | orange = medium pressure | red = high pressure.

The two main types of hydraulic gear pump

The image here illustrates an external gear pump (left) and internal gear pump (right).

External gear pumps use two external spur gears. Internal gear pumps use an external and an internal spur gear. Moreover, the spur gear teeth face inwards for internal gear pumps. As we have already said above, gear pumps are positive displacement (or fixed displacement). In other words, they pump a constant amount of fluid for each revolution. Some gear pumps are interchangeable and function both as a motor and a pump.

What can hydraulic gear pumps be used for?

Hydraulic gear pumps can be found in a wide variety of industries and applications. The petrochemical industry uses gear pumps to move: diesel oil, pitch, lube oil, crude oil and other fluids. The chemical industry also uses them for materials such as: plastics, acids, sodium silicate, mixed chemicals and other media. As a final example, these pumps are also used to transport: ink, paint, resins and adhesives and in the food industry.

We offer a wide range of hydraulic gear pumps for industrial and mobile applications and, because we are 100% independent, we can specify the model that is best suited to your needs

Piston Pumps

As the name suggests, a piston pump operates through pistons that move back and forth in the cylinders connected to the hydraulic pump. A piston pump also has excellent sealing capabilities.

Unlike gear pumps, piston pumps are usually variable displacement pumps. This means that you can change the amount of fluid displaced during a revolution – so you can control fluid displacement even when running at the same RPMs. As a result, variable displacement pumps are well suited in circuits where variable speeds or the ability to reverse is needed.

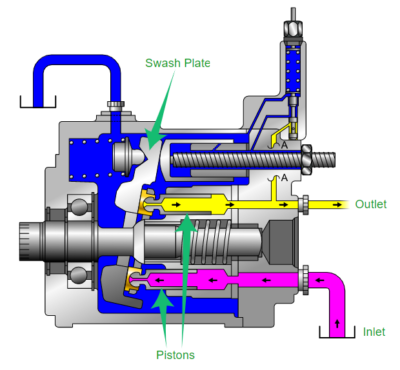

The image to the right depicts a variable displacement, pressure-compensated piston pump.

A piston pump performs flawlessly with large flows at high hydraulic system pressures. Applications commonly using a piston pump include: marine auxiliary power, machine tools, mobile and construction equipment, metal forming and oil field equipment.

A hydraulic piston pump can operate at large volumetric levels thanks to low oil leakage. Some plungers require valves at the suction and pressure ports, whilst others require them with the input and output channels. Valves (and their sealing properties) at the end of the piston pumps will further enhance the performance at higher pressures.

Let’s continue to take a look at axial piston pumps and radial piston pumps…

What are the features of an axial piston pump?

The axial piston pump is possibly the most widely used variable displacement pump. It is used in everything from heavy industrial to mobile applications. Different compensation techniques will continuously alter the pump’s fluid discharge per revolution. Moreover, they also alter the system pressure based on load requirements, maximum pressure cut-off settings and ratio control. This implies significant power savings.

Two principles characterise the axial piston pump. Firstly, the swashplate or bent axis design and, secondly, the system parameters. System parameters include the decision on whether or not the pump is used in an open- or closed circuit.

The return line in a closed loop circuit is under constant pressure. This must be considered when designing an axial piston pump that is used in a closed loop circuit. It is also very important that a variable displacement volume pump is installed and operates alongside the axial piston pump in the systems. Axial piston pumps can interchange between a pump and a motor in some fixed displacement configurations.

How does a bent axis, axial piston pump work?

Bent axis pumps are the most efficient of all hydraulic pumps.

The swivel angle determines the displacement volume of the bent axis pump. The pistons in the cylinder bore move when the shaft rotates. The swashplate, in the swashplate design, sustains the turning pistons. Moreover, the angle of the swashplate decides the piston stroke.

The bent axis principle, fixed or adjustable displacement, exists in two different designs:

- The first design is the Thoma-principle – a maximum 25-degrees angle, designed by the German engineer Hans Thoma and patented in 1935.

- The second design is known as the Wahlmark-principle, named after Gunnar Axel Wahlmark and patented in 1960. The latter features spherical-shaped pistons in one piece with the piston rod and piston rings. And moreover, a maximum 40 degrees between the driveshaft centre-line and pistons.

In general, the largest displacements are approximately one litre per revolution. However, if necessary, a two-litre swept volume pump can be built. Variable-displacement pumps are often used so that oil flow can be adjusted carefully. These pumps generally operate with a working pressure of up to 350–420 bar in continuous work.

About radial piston pumps

Radial piston pumps are typically used for high pressure and relatively small flows. Pressures of up to 650 bar are normal.

Plungers are connected to a floating ring. A control lever then moves the floating ring horizontally by a control lever and thus causes an eccentricity in the centre of rotation of the plungers. The amount of eccentricity is controlled to vary the discharge. Shifting the eccentricity to the opposite side seamlessly reverses the suction and discharge.

Radial piston pumps are the only pumps that work continuously under high pressure for long periods of time. Examples of applications include: presses, machines for processing plastic and machine tools.

Variable displacement is possible.

Vane Pumps

Vane pumps come in two different configurations: variable displacement or fixed displacement.

The type of displacement supported by a hydraulic pump is an important consideration that will impact the design of your hydraulic system. For example, if you want to change the displacement in a hydraulic system that uses a gear pump, you will need to change the speed of the prime mover in order to change the RPM of the pump.

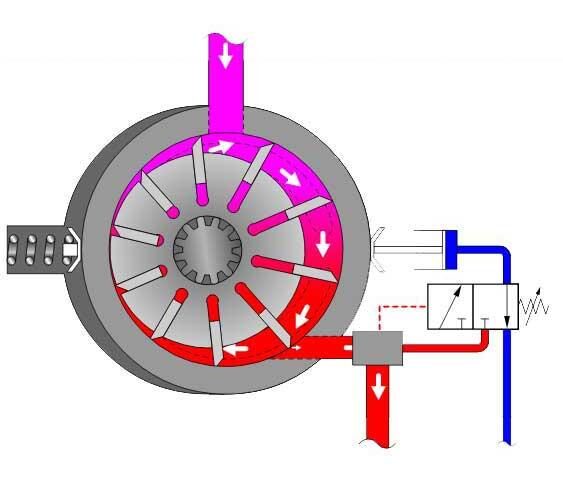

The image below is of an unbalanced, variable displacement, pressure compensated vane pump.

A vane pump uses the back and forth movement of rectangle-shaped vanes inside slots to move fluids. They are sometimes also referred to as sliding vane pumps.

The simplest vane pump consists of a circular rotor, rotating inside a larger circular cavity. The centres of the two circles are offset, causing eccentricity. Vanes slide into and out of the rotor and seal on all edges. This creates vane chambers that do the pumping work.

A vacuum is generated when the vanes travel further than the suction port of the pump. This is how the oil is drawn into the pumping chamber. The oil travels through the ports and is then forced out of the discharge port of the pump. Direction of the oil flow may alter, dependent on the rotation of the pump; this is the case for many rotary pumps.

Vane pumps operate most efficiently with low viscosity oils, such as water and petrol. Higher viscosity fluids on the other hand, may cause issues for the vane’s rotation, preventing them from moving easily in the slots.

Where are hydraulic vane pumps used? Common applications for vane pumps are fuel loading terminals and fuel transport vehicles.

Gerotor Pumps

A gerotor is a positive displacement pump. The name is derived from “generated rotor”. A gerotor unit consists of an inner and outer rotor.

Mathematical calculations are key to any type of hydraulic motor or pump design, but are especially interesting in the gerotor design. The inner rotor has N teeth, where N > 2. The outer rotor must have N + 1 teeth (= one more tooth than the inner rotor) in order for the design to work.

Learn more about hydraulic pumps

If you’d like to access more information about an introduction to hydraulic pumps, we highly recommend that you visit LunchBox Sessions’ website and make use of the fabulous resources available there.

Some of the sessions are free; you don’t need to sign up. However, if you are serious about expanding your knowledge of hydraulic systems, we recommend you consider signing up for a subscription to the entire LunchBox Session service. This way, you get full access to all the interactive training materials, tests and simulations for just $29 per month. Students are entitled to a 60% discount off this price when they share their college or university ID.

If you’re looking for more information and advice on hydraulic pumps suitable for your own hydraulic system, please get in touch with our helpful team for guidance and quotations. Contact us here.

We’re a hydraulics ‘hub’, offering thousands of possibilities… how can we help?

Frequently asked questions and answers about hydraulic pumps

Which hydraulic pump brands do you provide?

We have direct access to over 80 leading hydraulic brands. This means that we offer agile and flexible solutions to suit every customer’s budget, lead-time and specifications. Some of our bestselling brands include: Bosh Rexroth pumps, B&C Hydraulics pumps, Casappa pumps, Danfoss pumps, Dowty pumps, Parker Hannifin pumps and Vivolo Vivoil pumps and Voith pumps. Our team will work closely with you to advise on the best hydraulic pump for your system and application.

Can you get hold of an identical pump to the one that we’re already using?

Yes, if you have the manufacturer’s name and product number, we can source any pump still listed in the market. If the pump is now obsolete, our skilled team are able to source direct equivalents. In some instances, this means we can also offer better lead-times and reduced cost.

Do you manufacture custom-made hydraulic pumps?

We do not manufacture our own pumps. However, our independence allows us to access leading and niche hydraulic pump manufacturers. We are confident that we will be able to source a pump, which meets your exact requirements.

You are welcome to get in touch. We can also help with bespoke cylinders or bespoke power pack builds.

What is your lead-time for a new pump?

We don’t just shift boxes. Our technical expertise, industry knowledge and independence combine to ensure that we are second to none when it comes to agility. In most cases we can deliver a new pump within days, or even the same day where possible.

Do you ship worldwide?

Yes! If it’s hydraulic we can design it, supply it, solve it, repair it… and ship it worldwide! To date, we have supported customers in 130 countries and are viewed as the UK’s hydraulics solutions “gateway” to the rest of the world. In 2019, the UK Government’s Department for Business and Trade appointed Hydraulics Online as a Northern Powerhouse Export Champion.

Do you repair pumps?

Of course! Many of our repaired and refurbished hydraulic pumps are virtually indistinguishable to a brand-new unit. Our service includes a free consultation. Thereafter our technical engineers can proceed with a full diagnosis and will contact you to discuss all options available and identify the best solution for your specific needs.

If applicable, our team will also offer recommendations on how to future-proof your pump’s performance to save costs and minimise system downtime in the future.

Return to our Hydraulic Pumps Catalogue

More hydraulic pump guidance from our Technical Knowledge Hub…

Preventing Hydraulic Pump Cavitation with better Inlet Maintenance

You may know that properly maintaining a hydraulic pump will ensure maximum efficiency and prevent damage, but did you know that it is especially critical to regularly monitor inlet conditions?

Poor inlet conditions can result in cavitation—the second leading cause of pump failure. So what is pump cavitation and how can you prevent it?

Learn moreSelecting Hydraulic Fluid for your Hydraulic Pump

The hydraulic fluid is one of the most important components in the system yet it is often overlooked…

The fluid is the medium for the transmission of power and without sufficient fluid, no work can take place. It also performs functions such as lubrication, heat transfer and allows the conveyance of debris and contamination.

Read moreParker Gold Cup: Six Things you never Knew about Heavy Duty Hydrostatic Piston Pumps and Motors

You probably know that the heavy-duty Gold Cup series of pumps and motors represent Parker’s and Denison’s combined expertise in hydrostatic transmission applications. But you possibly don’t know of these six value-added features and benefits…

Discover moreExplore our other collaborations with Lunchbox Sessions…

An Introduction to Hydraulic Pressure and Flow

An understanding of the key principles of fluid dynamics is, essential for anyone who wishes to build or maintain hydraulic systems.

One of the first concepts that must be understood is how physicists quantify the movement of fluids, namely flow.

Learn MoreDiagnosing Problems using Pressure Readings

Effective troubleshooting of problems in hydraulic systems requires a good understanding of flow and pressure readings.

In this article, we look at how pressure and flow can vary depending on the type of hydraulic system and what implications this has for hydraulic system troubleshooting.

Learn moreTroubleshooting Hydraulic Systems: the Reservoir, Breather and Fluid Contaminants

The hydraulic reservoir plays a crucial role in hydraulic circuit design – storing hydraulic fluid when it isn’t being pushed through the hydraulic system.

While a “fluid storage tank” might seem like a very simple concept, the design and implementation of the reservoir is very important.

Learn more