Whatever you design or build to engineer a better world, Parker are known for enabling engineering breakthroughs that lead to a better tomorrow.

Founded in 1918, Parker are a global leader and Fortune 250 company – their innovative solutions have enabled countless technology leaps over the years.

Today, Parker is recognised as the world’s leading fluid motion control manufacturer, operating in 309 locations across 50 countries. With over 100 years of experience, Parker is one of the most trusted brands in the business.

Their innovations help engineers working in many industries and locations worldwide, including: Industrial Manufacturing, Off-Road Machinery, Power Generation, On-Road Transportation, Life Science & Healthcare and Oil & Gas.

Parker Hannifin's Vision – Engineering Your Success

Parker’s vision is to help people solve the world’s greatest engineering challenges – like saving lives, reducing emissions and purifying water.

They offer an unmatched range of technologies including electrification, hydrogen, and alternative fuels. This breadth of expertise, gained from decades supporting 1,000+ markets globally.

Sustainable Operations

The company is actively playing its part to build a cleaner, brighter future by reducing greenhouse gas intensity and energy intensity, cutting water and working safely, in line with their aim of being completely carbon neutral by 2040.

Currently, two-thirds of Parker’s portfolio enables clean technologies, supporting customers’ emission reduction strategies through a broad range of solutions.

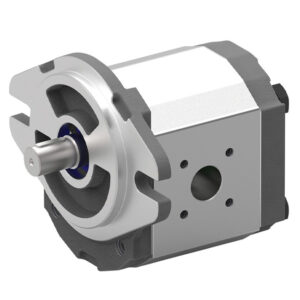

Hydraulics is one of the nine core motion and control technologies that Parker delivers. Their hydraulic product range includes: pumps, motors, valves, fittings and adaptors, alongside other accessories.

Please contact us for further technical guidance or if you cannot see the Parker hydraulic equipment that you need listed below – we’ll be happy to help!

Parker Hydraulics Product Range

Parker Hydraulic Valves

Parker Cartridge Valves

Parker Check Valves

Parker Directional Control Valves

Parker Pressure Reducing Valves

Parker Pressure Relief Valves

Parker Unloading Valves

Parker Valves – Other

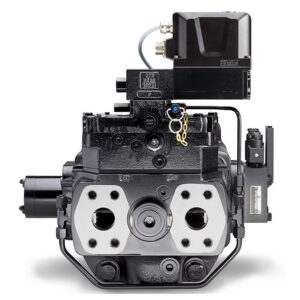

Parker Gold Cup Pumps and Motors

Parker Hydraulic Accumulators

Parker Hydraulic Motors

Parker Bent Axis Motors

Parker Brake Motors

Parker Gear Motors

Parker Gerotor Motors

Parker Radial Piston Motors

Parker Vane Motors

Parker Hydraulic Pumps

Parker Gear Pumps

Parker Gerotor Pumps

Parker Piston Pumps

Parker Vane Pumps

Parker Hydraulics News and Insights

Six things you never knew about Heavy-Duty Hydrostatic Piston Pumps and Motors

Parker Gold Cup heavy-duty pumps and motors have long been respected in the industry for technical excellence in hydrostatic transmission applications in marine, drilling, and shredding applications, among others.

You are also probably aware that the heavy-duty Gold Cup series of pumps and motors represent Parker’s and Denison’s combined expertise in hydrostatic transmission applications.

But you may not be aware of Gold Cup’s, heavy-duty hydrostatic piston pump and motor value-added features and benefits…

10 Frequently asked Questions you should know about Power Take-Offs

A Power Take-Off, or PTO, gives a truck versatility beyond its usual function of providing transportation for materials. It directs power to the auxiliary equipment to perform work at the site and/or enroute.

A PTO can eliminate the need for a second, or auxiliary, engine to power the equipment. Efficiency is gained through a PTO being applied to any form of vehicle transportation application including dump trucks, garbage trucks, snow trucks and many more.

Three reasons to choose the Parker V16 Variable Displacement Hydraulic Motor for your Mobile Application

Parker’s Series V16 is the next generation of variable displacement, bent-axis motors. It further develops their well-known V12 and V14 hydraulic motor series.

It is designed for both open and closed circuit transmissions focusing on high-performance machines and demanding mobile applications. Rigorous product testing and continuous product development help to ensure our hydraulic motors operate at optimum efficiency and outperform in the most demanding environments.

Advantages of Helical Hydraulic Actuators in Heavy-Duty Applications

Hydraulic actuators cause engineered equipment to move, slide, rotate and lift by converting energy from pressurized fluid and hydraulic power units.

Depending on the type of machinery involved and the desired movement needed, there are a variety of linear and rotary actuators available to best match the needs of the designer.

»

»

Rayco Stump Cutter uses Parker Pump and Motor Combination

Following the introduction of more stringent Tier IV diesel engine emissions regulations, Rayco, an environmental equipment designer for the tree care and landscape industries, developed a more efficient, powerful and compact stump cutter, the RG165T-R, centered around a powerful 165 HP gasoline engine.

Check Valves are the Unsung Heroes of Fluid Power

Check valves are unseen and undervalued – despite the fact that these valves are found in just about every mobile and industrial hydraulic system on the planet. Simply put, if there’s a pump, most likely you will find a check valve. Check valves keep the fluids flowing in the desired direction to prevent damaging flow or pressure in the reverse direction.

Read moreHow do Parker Bladder Accumulators Work?

Have you ever wondered how hydraulic accumulators work? This 60-second, high-quality animation by Parker Hannifin makes the inner workings of a bladder accumulator extremely clear and easy to understand!

Parker is the leading manufacturer of bladder accumulators in North America. The bottom repairable design, due to its simplicity and cost effectiveness, has become the de facto “Industry Standard” bladder accumulator.

Subscribe to our newsletter to receive more free technical guides, product insights and resources…

Get in Touch

"*" indicates required fields