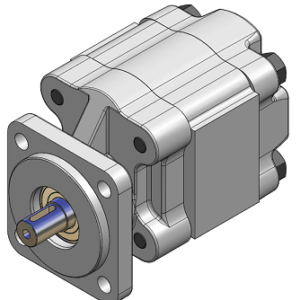

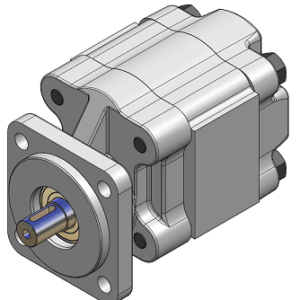

External Gear Motors – Compact, Efficient Hydraulic Drive

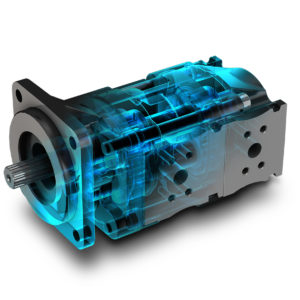

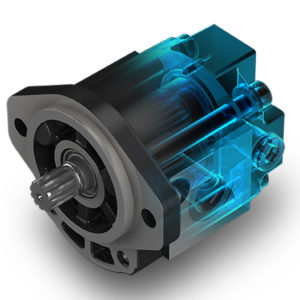

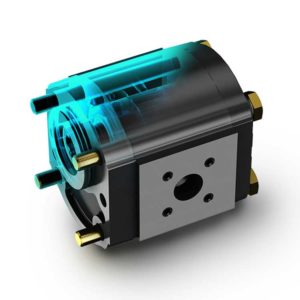

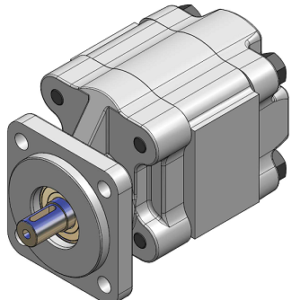

External gear motors are widely used in hydraulic systems that demand a compact footprint and dependable performance. These fixed displacement units convert hydraulic energy into rotary motion using two precision-cut gears: a driven gear linked to the output shaft, and a free-spinning idler gear.

Operating Principle

Pressurised fluid enters the motor body and travels around the gear profiles, between the gear tips and the housing wall, toward the outlet. As the gears interlock, they block reverse flow – maintaining consistent torque. A small volume of oil is diverted for internal lubrication, routed through hydrodynamic bearings and vented either to the low-pressure side or via a dedicated drain port.

Performance Highlights

- Fixed displacement for consistent output

- Compact, lightweight construction

- Operating pressures typically between 100–150 bar (up to 250 bar in newer models)

- Handles a wide range of temperatures and fluid viscosities

- Cost-effective with flexible speed options

- Wears gradually over time – reducing risk of sudden failure

- Available in unidirectional and reversible formats

Sound Profile

External gear motors may produce more noise than other hydraulic motor types due to gear interaction. However, their simplicity, reliability, and low cost make them a practical choice in many systems.

Explore Our Ultimate Guide to Hydraulic Motors

Curious about how hydraulic motors work or which type suits your application? Our free Ultimate Guide to Hydraulic Motors introduces the key motor types, their operating principles, and typical use cases – helping you make informed, confident decisions.

Worldwide Supply & Brand Flexibility

We provide independent access to over 80 leading hydraulic brands, including Bosch Rexroth, Parker, Vivolo, Eaton, Salami, Permco, and many more. Whether you need a standard gear motor or a tailored configuration, our team will help you source the right part – quickly and without bias.

With recognised export capabilities to over 130 countries, we support professionals across 20+ industries – from agriculture and marine to manufacturing and energy.

Frequently Asked Questions

What is an external gear motor used for? These motors are ideal for hydraulic systems where space is limited and consistent torque is needed – commonly found in mobile and industrial machinery.

Can external gear motors run in reverse? Yes. Reversible models feature a symmetrical build and dedicated drain ports, enabling bidirectional flow and series circuit compatibility.

Are external gear motors noisy? They can be louder than other motor types due to gear meshing, but their durability and simplicity often outweigh this drawback.

Need Help Choosing the Right Hydraulic Motor?

Our award-winning technical team is here to help. Whether you’re replacing a unit, designing a new system, or comparing brands, we’ll guide you to the best-fit solution – quickly and confidently.

We supply:

Hydraulic Pumps | Hydraulic Valves | Hydraulic Cylinders | Hydraulic Filters | Custom Hydraulic Power Packs | Hydraulic Motor Repair Service | …and more Hydraulic Components and Accessories

Our website showcases just a selection of what we supply. For impartial advice and access to thousands more hydraulic components, contact our expert team – wherever you are.

Product Categories

-

Aluminium Gear Motors

40 products

-

Cast Iron Gear Motors

65 products

Can’t find what you’re looking for? Contact us.

Products

Can’t find what you’re looking for? Contact us.